System and method for treating Qinghai-Tibet-plateau low-temperature and anoxic slaughter wastewater

A technology of slaughter wastewater and treatment system, which is applied in the direction of filtration treatment, multi-stage water treatment, energy wastewater treatment, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

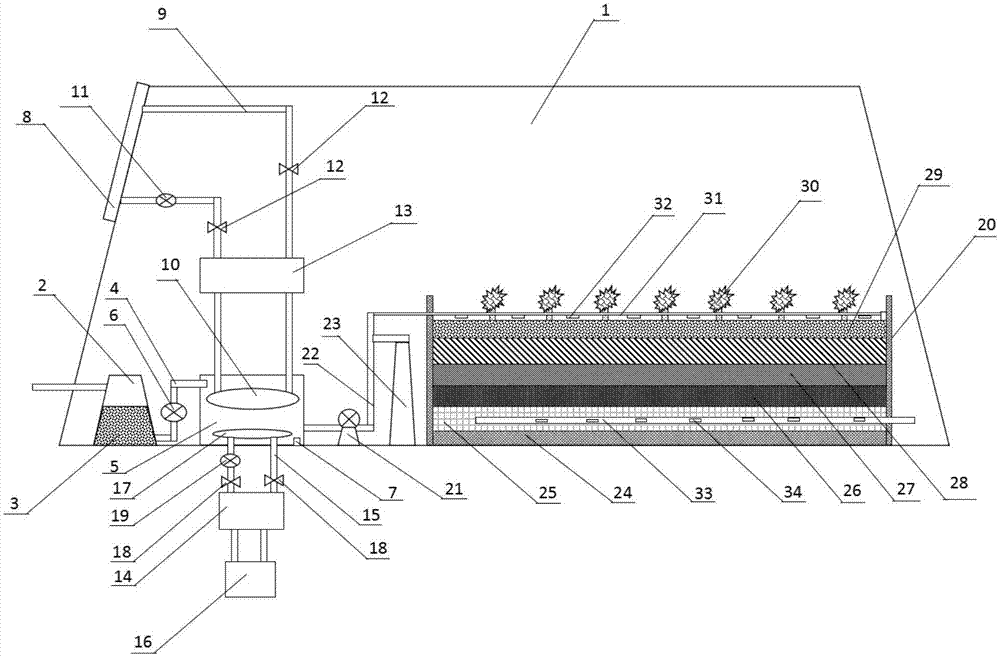

[0050] A method for treating Qinghai-Tibet Plateau low-temperature anoxic slaughter wastewater, comprising:

[0051] Transport the low-temperature anoxic slaughter wastewater from the Qinghai-Tibet Plateau to the slaughter wastewater pretreatment device of the greenhouse system 1, pass through the gravel filter layer 3, and then transport the filtered slaughter wastewater to the water temperature adjustment pool 5 through the first water pump 6, and in the water temperature adjustment pool The temperature sensor 7 detects the temperature of the slaughter wastewater, and transmits the temperature signal to the PLC control system. After the control system receives the temperature signal, it compares it with the preset upper and lower limit temperatures in the control system. When it is lower than the set upper and lower limit temperature (15 ℃), the control system controls the opening of the first circulating water pump 11 and the first valve 12, and heats the circulating water i...

Embodiment 2

[0058] The preparation method of the heavy metal adsorption layer is in parts by weight: by weight, take 25 parts of biogas residue, 8 parts of humus, 4 parts of biochar, 4 parts of diatomaceous earth, 4 parts of sodium lignosulfonate, 100 parts of hot water Put the spherical container in a stainless steel spherical container, place the spherical container on a four-axis grinder, turn on the four-axis grinder, drive the stainless steel spherical container to rotate randomly for 30 minutes, and then directly dry and crush the reacted mixed solution to obtain a composition of heavy metal adsorption layer of powder; the feed port of the stainless steel spherical container is sealed by a threaded cap, and the threaded cap is sealed and connected flush with the surface of the stainless steel spherical container; the driving shaft speed of the four-axis grinder is 120rpm, and the random transition frequency is 30s;

[0059] It is identical with process parameter and process and in e...

Embodiment 3

[0062] The preparation method of the heavy metal adsorption layer is in parts by weight: by weight, take 30 parts of biogas residue, 10 parts of humus, 3 parts of biochar, 5 parts of diatomaceous earth, 3 parts of sodium lignosulfonate, 120 parts of hot water put the spherical container on the four-axis grinder, turn on the four-axis grinder, drive the stainless steel spherical container to rotate randomly for 60 minutes, and then directly dry and crush the reacted mixed solution to obtain the composition of heavy metal adsorption The powder material of layer; The feed inlet of described stainless steel spherical container is sealed by threaded cap, and the surface of the stainless steel spherical container is flush with the threaded cap sealing connection; The driving shaft speed of described four-axis grinder is 150rpm, and random conversion frequency is 60s;

[0063] It is identical with process parameter and process and in embodiment 1.

[0064] The method of this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com