Method for determining acceleration factors in EM testing structure

A technology of test structure and acceleration factor, which is applied in the direction of electronic circuit test, measuring circuit, measuring device, etc., can solve the problems of occupying too many experimental resources and cumbersome operation, and achieve the effect of saving experimental resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

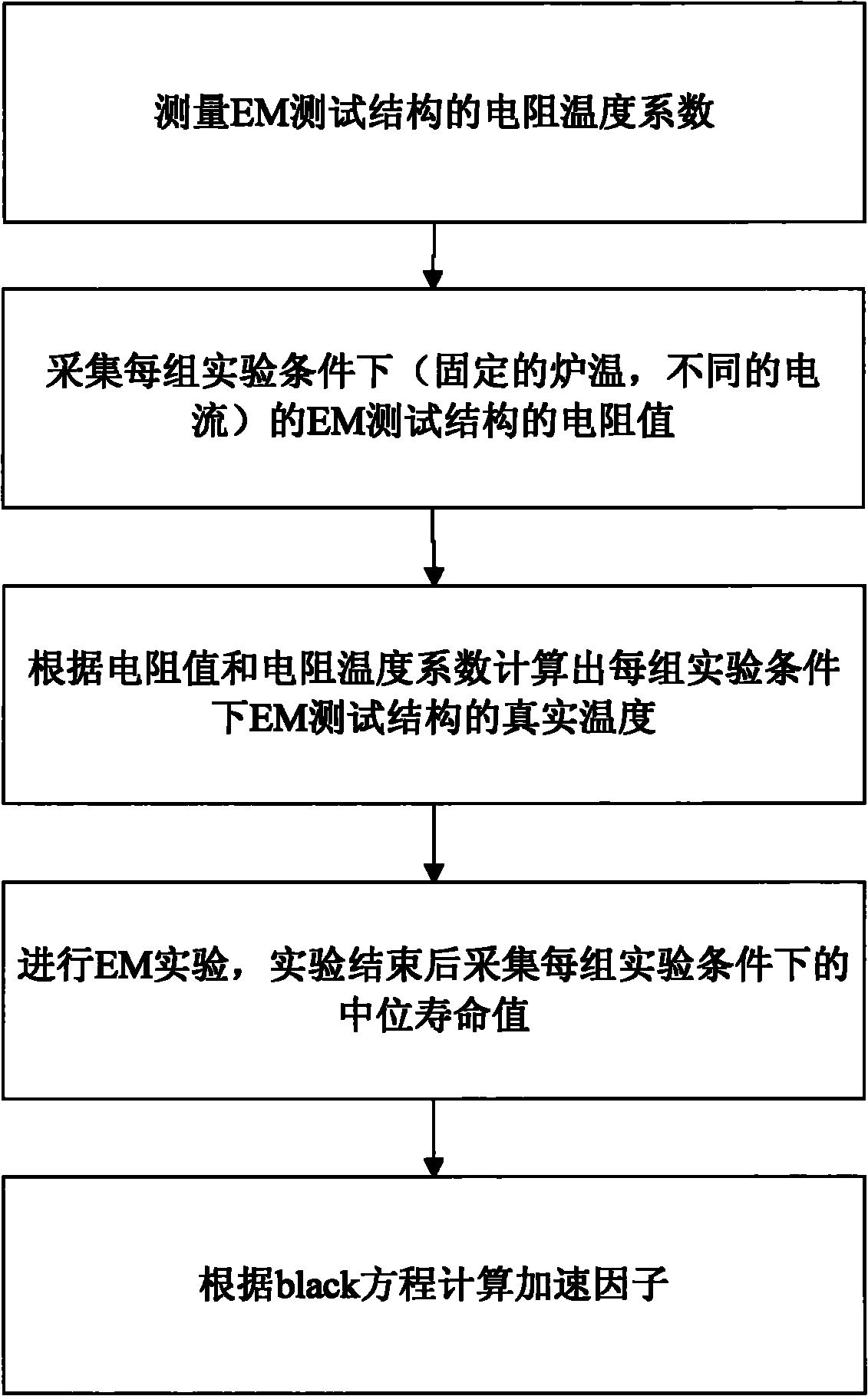

[0032] The method of determining the acceleration factor in the EM test structure of the present invention is also carried out in a commonly used furnace chamber, which is to set the temperature of the furnace chamber at a fixed temperature, and add different current densities to the EM test structure. carry out testing.

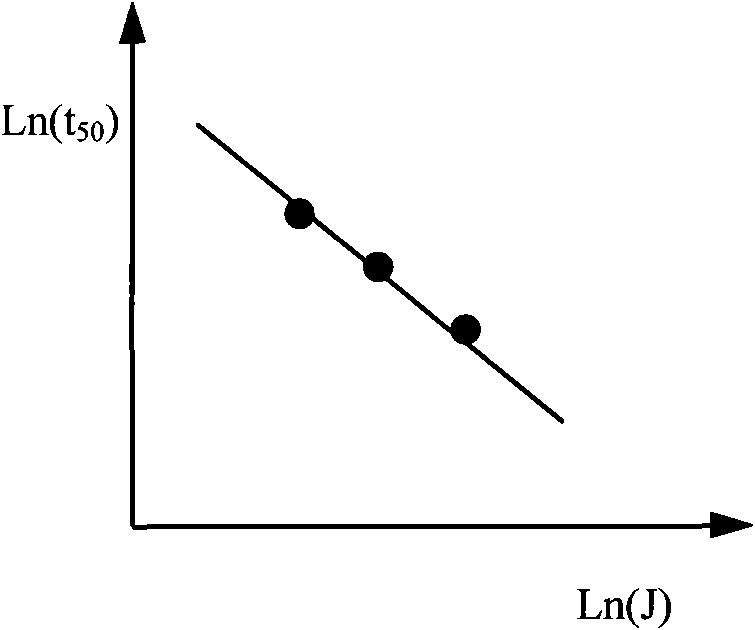

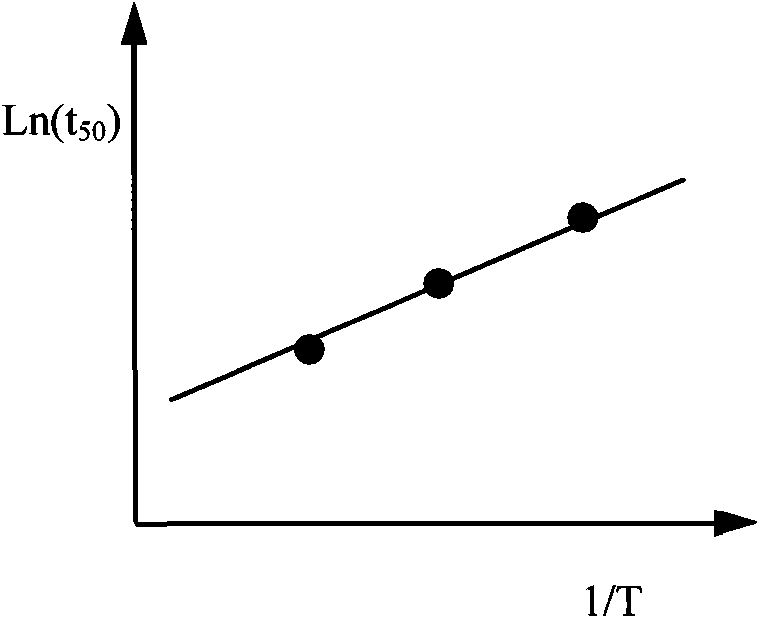

[0033] Such as image 3 As shown, the present invention includes the following steps:

[0034] First, in the process of heating the furnace chamber to the set temperature, measure the voltage across the EM test structure at a certain temperature through a small current, and then calculate the resistance, and calculate the EM based on the temperature and the measured resistance. Test the temperature coefficient of the structure.

[0035] In the above process, in order to accurately measure the temperature coefficient of resistance, in addition to using some resistance-temperature data, it is also necessary to control the size of the current, so that no Joule heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com