Sheet heat polyunit with real-time temperature control function

A lamination device and control function technology, applied in the field of thin sheet thermal lamination devices, can solve the problems of large covering range, fast heat loss, and large volume of heat conduction box 22, and achieve the effects of cost reduction, quality improvement, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

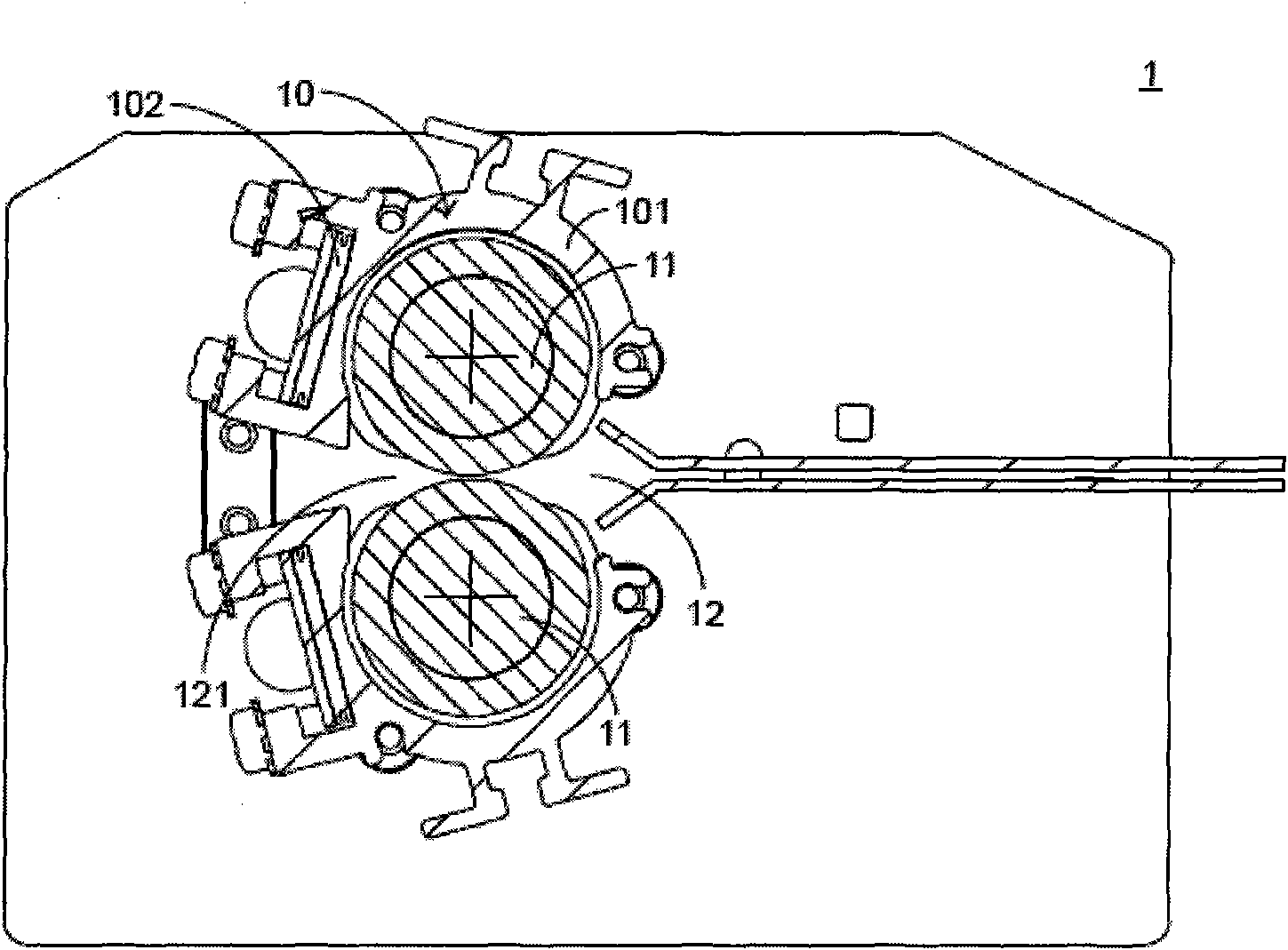

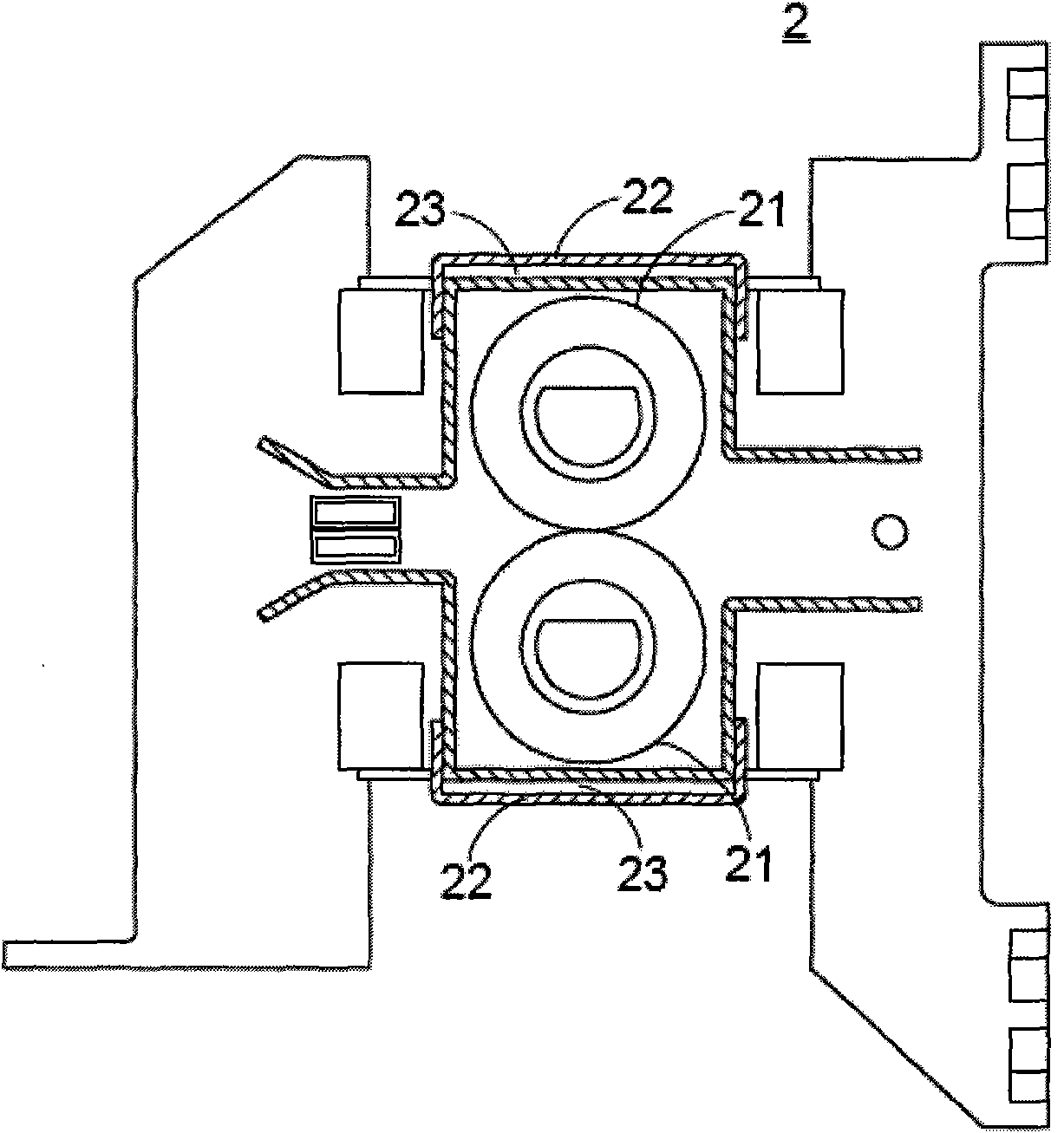

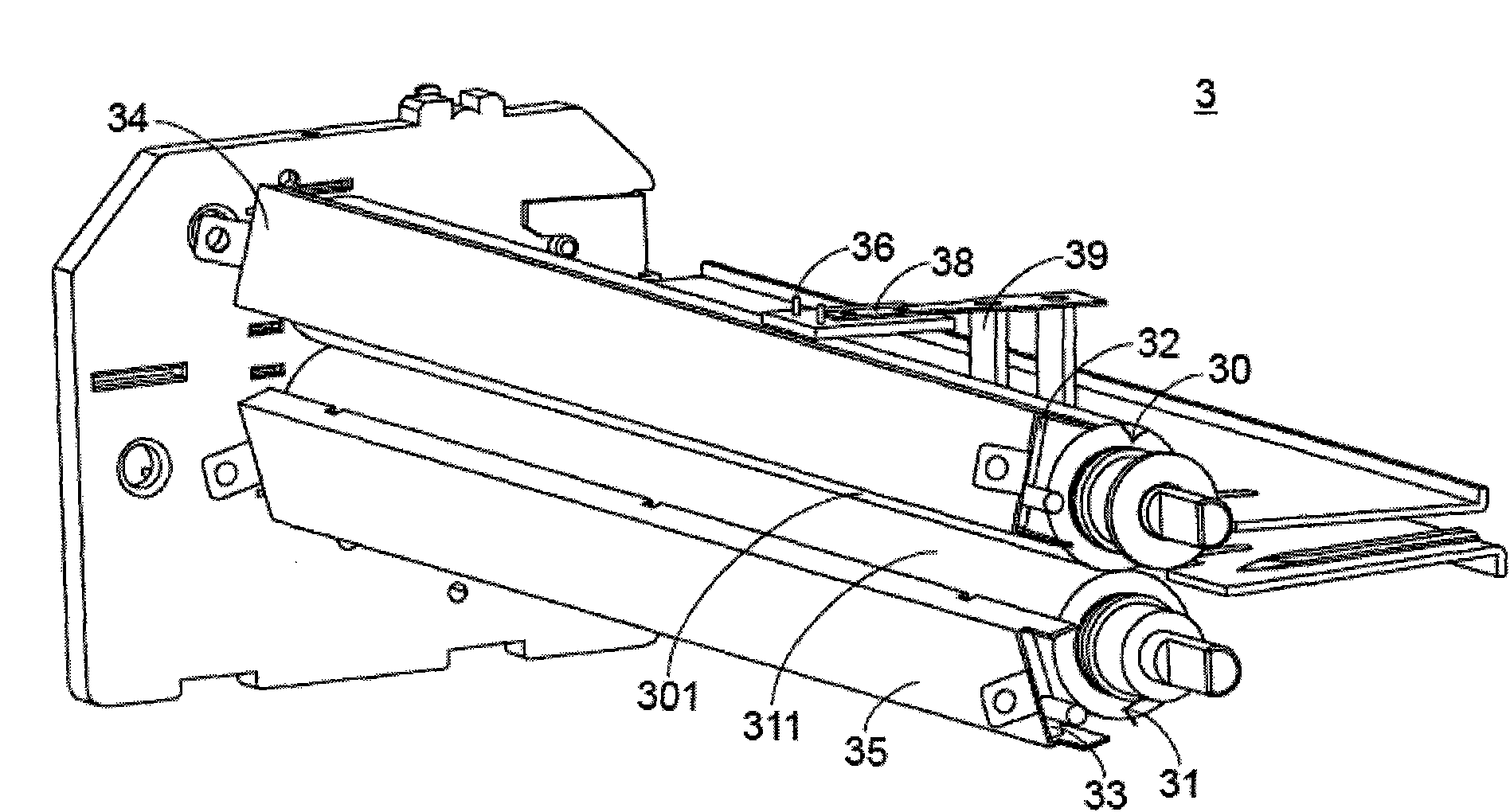

[0027] see image 3 and Figure 4 , image 3 It is a schematic diagram of the appearance structure of a preferred embodiment of the sheet thermal lamination device with real-time temperature control function in the present invention, Figure 4 It is a side view of the appearance structure of a preferred embodiment of the thermal lamination device with real-time temperature control function of the present invention. Sheet thermal lamination device 3 includes a first elongated roller 30 with a first roller surface 301, a second elongated roller 31 with a second roller surface 311, first and second elongated metal sheets 32, 33, a first With the second electric heating box 34,35, contact sensor 36 and controller 37 (see Figure 5 ).

[0028] Wherein, the first roller surface 301 is in contact with the second roller surface 311 . And the first elongated metal sheet 32 is covered by the first electric heating box 34, and is positioned at one side of the first elongated rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com