Double-deck container flat car

A container and flat car technology, applied in the direction of trucks, transport buses, transportation and packaging, etc., can solve the problem of not being able to carry road semi-trailers, and achieve the effects of safety and high adaptability, improving safety and reliability, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention is further described below in conjunction with embodiment. The examples serve to illustrate the invention, but do not limit the invention in any way.

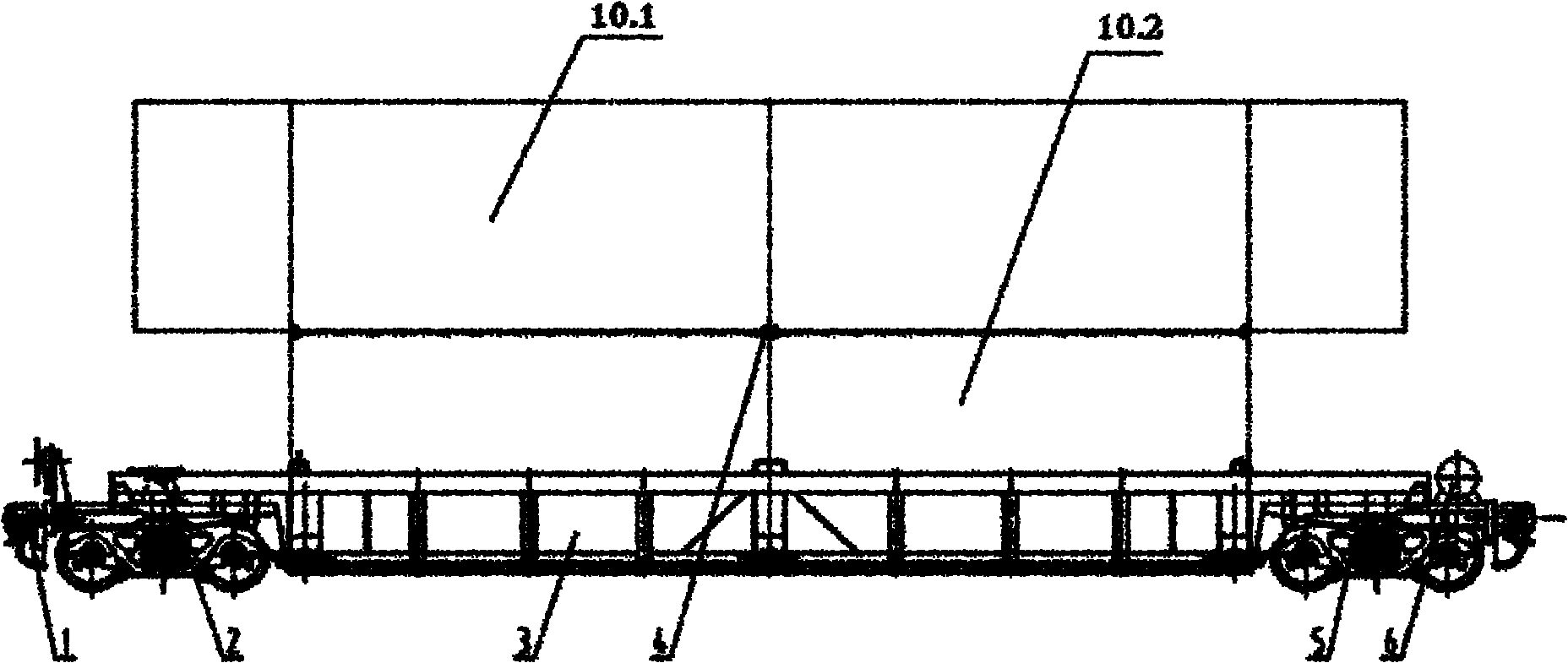

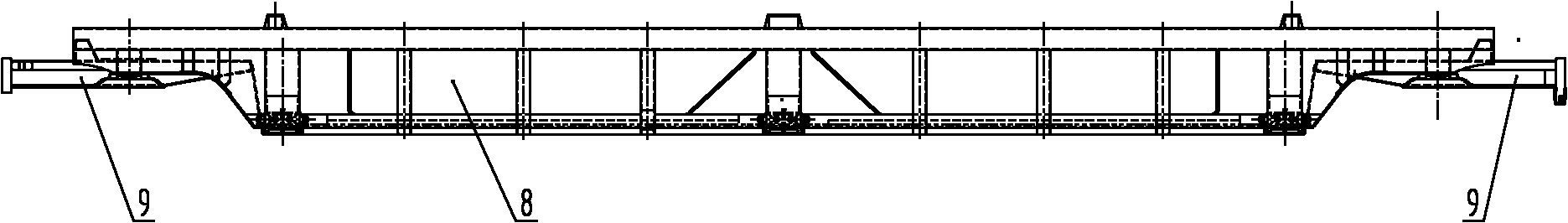

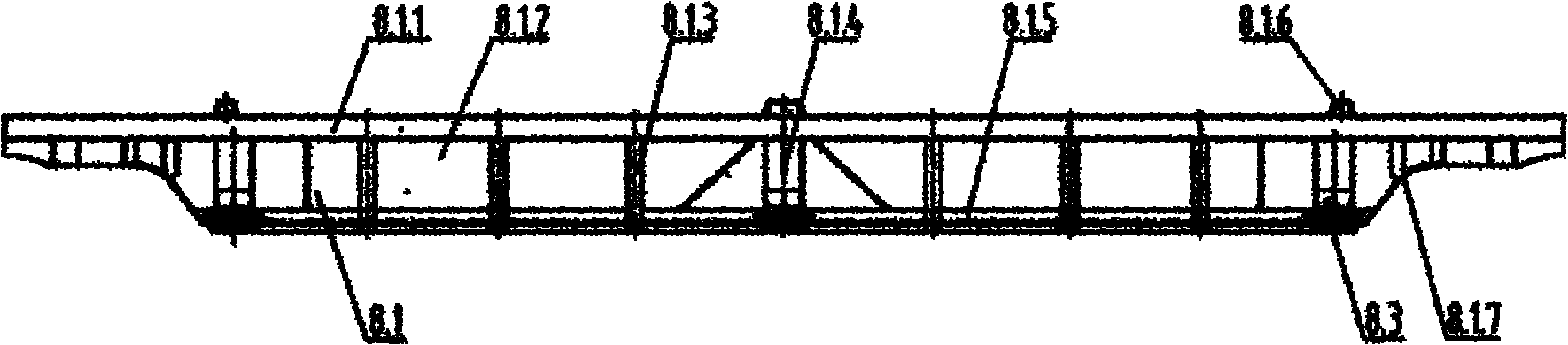

[0048] figure 1 It is a schematic diagram of the state of carrying double-deck containers in the present invention, figure 2 It is a schematic diagram of the vehicle body longitudinal side structure of the present invention. As shown in the figure, the double-deck container flat car of the present invention includes a coupler buffer device 1, a semi-trailer support seat 2, a car body 3, an upper and lower container locking mechanism 4, a bogie 5, a braking device 6 and a container fixed lock Mechanism 7, wherein, the car body 3 includes a large underframe 8 and a sleeper pulling device 9 . The illustration in the figure shows the working condition of loading and fixing a total of four 20ft containers on the upper and lower floors, which is only a combination of loading conditions in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com