Guiding device of counterweight housing of elevator

A technology of guiding device and counterweight frame, which is used in elevators, transportation and packaging, elevators and other directions in buildings, which can solve the problems of long guide rails, complex structure, and difficulty in ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

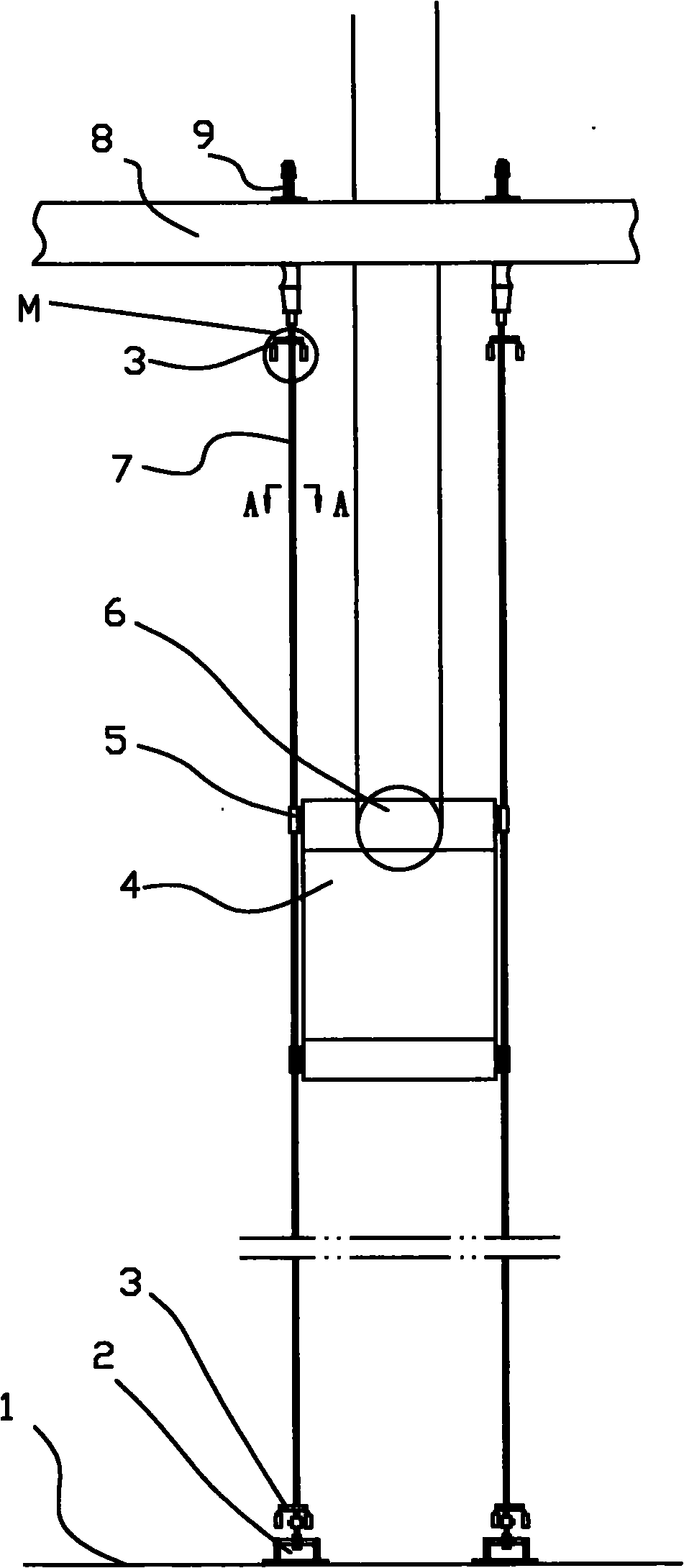

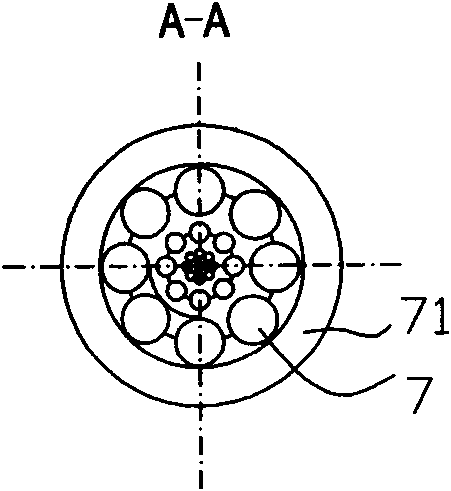

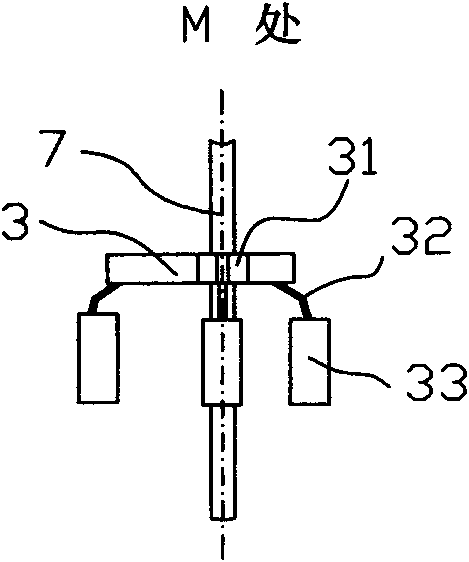

[0018] The present invention as Figure 1-4 As shown: the counterweight frame 4 is set in the elevator shaft, and its upper end is connected to the lifting device 6, and the counterweight frame 4 runs between the bottom 1 and the top 8 of the building, and between the top 8 and the bottom 1 of the elevator shaft There is a pair of guide cables 7, the two sides of the counterweight frame 4 are connected with the guide cables 7 through the guide sleeves 5; the guide cables 7 are tightened by the locking chuck 2 at the lower end and the guide cable tightening device 9 at the upper end Between the bottom of the building 1 and the top of the building 8; the upper part of the locking chuck 2 and the guide cable 7 of the lower part of the guide cable tightening device 9 are fixedly connected with a shock absorber 3; the shock absorber 3 includes a disc-shaped body 31, and two to four weights 33 are connected to the outside of the body 31 through elastic steel cables 32 respectively. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com