Method for weaving shedding-resistant velvet knitted fabric

A knitted fabric, velvet velvet technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of not full plush, not full bottom yarn and veil, thin density, etc., to achieve solid internal quality and human health. Beneficial, firmness-increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

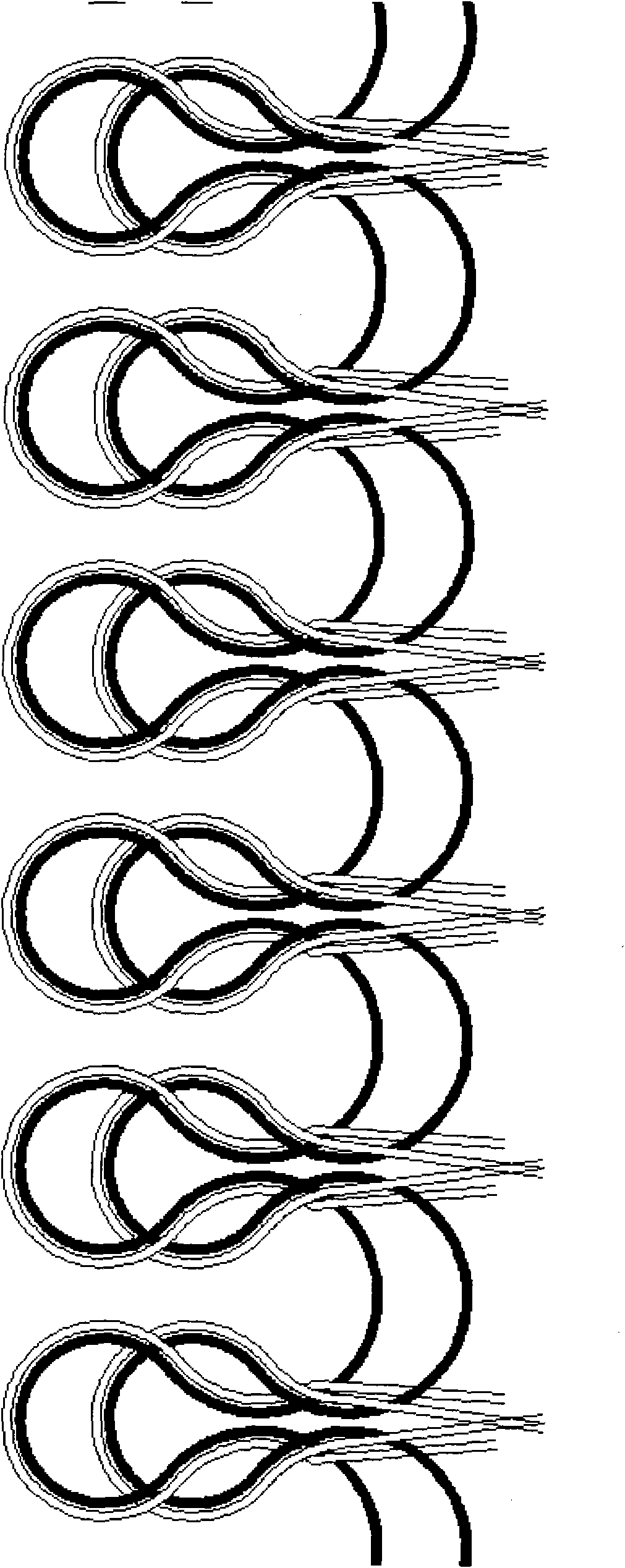

[0040] A method for weaving a velvet knitted fabric that prevents velvet from falling off according to the present invention. The velvet knitted fabric includes a bottom surface formed by a ground yarn and a suede surface formed by a veil. There are two knitting needles between the pile parts, the first knitting needle and the second knitting needle simultaneously hook the top yarn and the bottom yarn to form a fixed yarn loop;

[0041] Specific steps are as follows:

[0042] (a), drive the hook yarn knitting needle to the yarn feeding position, and feed the veil bottom yarn into the hook yarn knitting needle;

[0043] (b), drive the pile machine to the yarn feeding position, and feed the veil into the pile machine;

[0044] (c), the hook yarn knitting needle is retracted to the loop-off position;

[0045] (d), driving the napping mechanism to the plush forming position;

[0046] (e), move the pile machine part in parallel for a distance between knitting needles, and repeat...

Embodiment 2

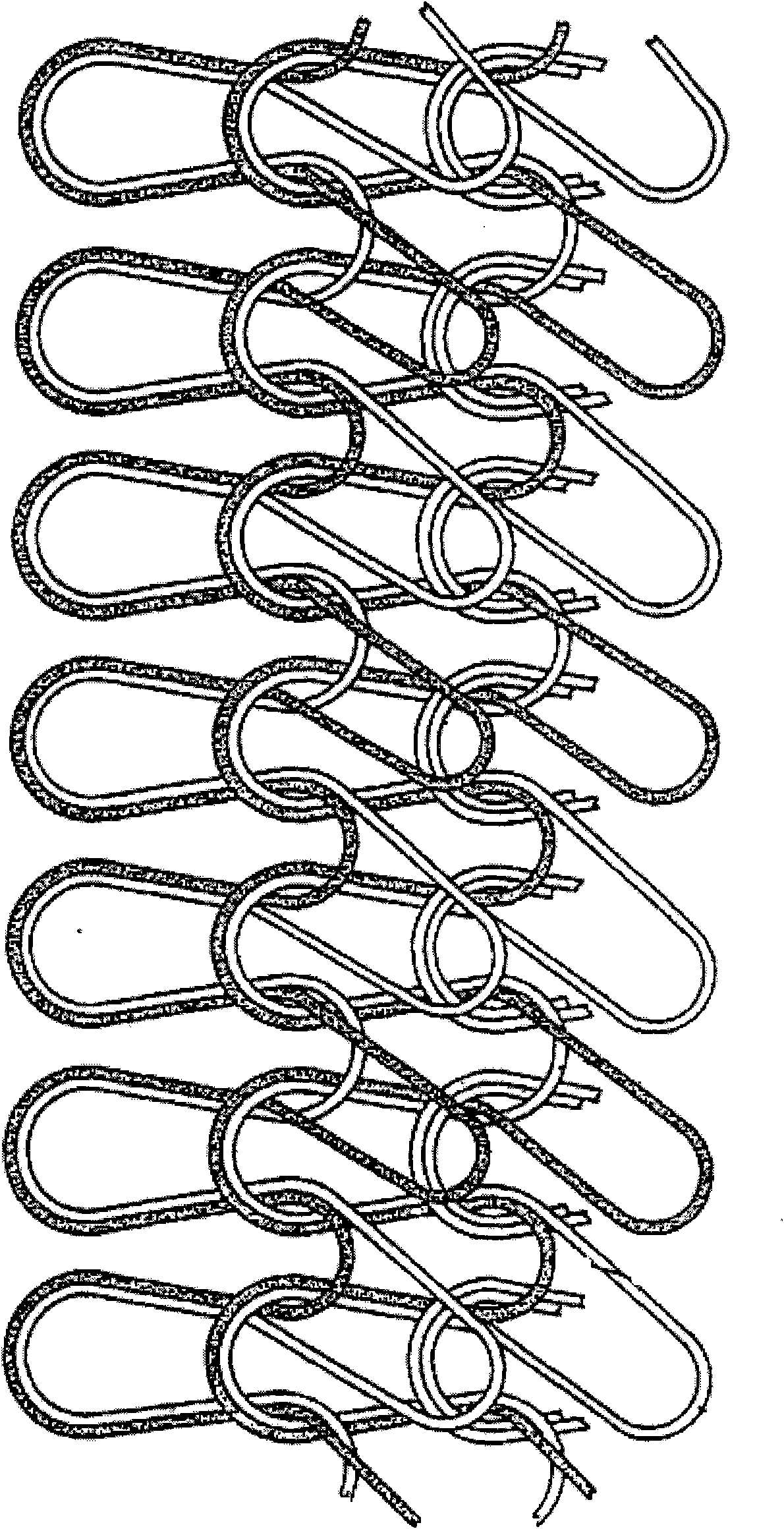

[0049] The velvet knitted fabric includes a bottom surface formed by a ground yarn and a suede surface formed by a veil, and the weaving machine includes a set of pile components and a set of hook yarn knitting needles, and a hook yarn knitting needle is separated from the pile components. , the odd-numbered parts of the pile machine are controlled by one drive, and the even-numbered parts are controlled by another drive;

[0050] Specific steps are as follows:

[0051] (a), drive the hook yarn knitting needle to the yarn feeding position, and feed the veil bottom yarn into the hook yarn knitting needle;

[0052] (b), drive the pile parts of the odd part to the yarn feeding position, drive the pile parts of the even part to the empty needle position, and feed the veil into the pile parts of the yarn feeding position;

[0053] (c), the knitting needle is retracted to the stripping position;

[0054] (d), drive the pile mechanism that feeds the veil to the plush forming positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com