Method for applying pre-stress to fiber sheet by using multiple parallel rods

A fiber sheet, prestressing technology, applied in the processing of building materials, building maintenance, bridge maintenance, etc., can solve the problems of unsatisfactory size and anchoring effect, improve the utilization efficiency and scope of application, overcome the vulnerability The effect of force peeling and saving of expensive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

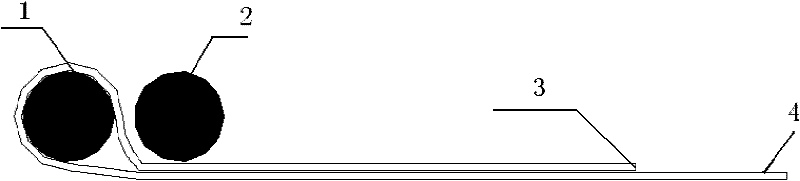

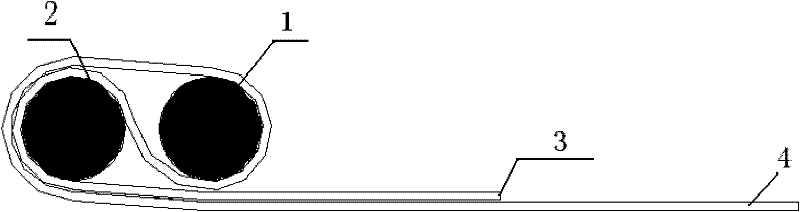

[0036] Figure 4 , Figure 5 1 Example of Prestressing a Parallel Rod Anchor Using Flexible Sheet Material: Using Figure 5 (a) The anchorage part shown in (a) can be completed Figure 4 The shown fiber sheet is self-locked around the pole and continues to be around, and then installed on the structural member, Figure 5 In (a), the joint-shaped rod with holes and the rod passing through the component are used; the joint-shaped hole-shaped rod and the rod passing through the component are still used. Figure 5 (b) The anchorage part shown in (3 of which has been connected as a whole through the side plate) is preliminarily installed on the structural member; then apply pressure with the aid of jacks and other equipment, or slowly tighten the end of the joint-shaped rod with holes Nuts, the anchored sheet is pushed into the part of the outer section of the rod between the rods through the embedding strip, and the sheet will gradually obtain prestress; the embedding strip tha...

Embodiment 2

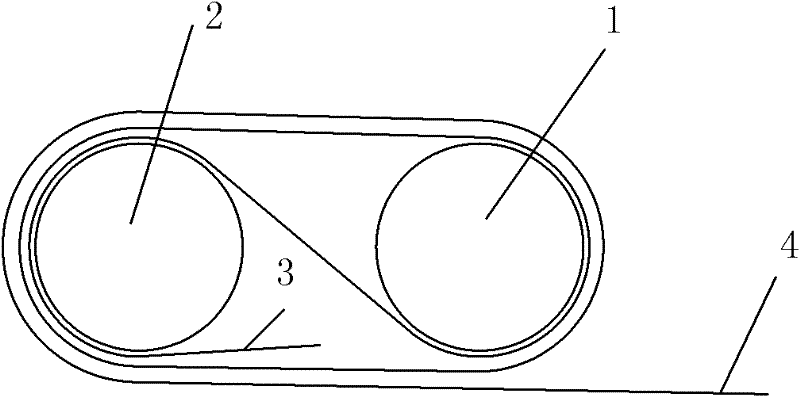

[0038] Image 6 An example of the combination of flexible sheet material parallel rod anchors and independent rods: Prepare 1 independent rod and flexible sheet material parallel rod anchors (the number of rods in the anchorage in this figure is 2 root, the parallel piece that connects two parallel rods together is a strip sheet) and a rod-shaped insert; a group of movable joint-shaped rods with holes are pre-pierced on the independent rods, and the joint-shaped rods with holes Scattered arrangement, the clear distance between adjacent joint-like rods with holes is not less than the width of the sheet; the sheet is wound around an independent rod and an adjacent rod in the anchorage to form a knotted After encircling, continue to surround the common periphery of the encircling envelop and another rod in the anchorage; pass the joint-shaped perforated rod through the pre-prepared through hole on the structural member and then tighten the nut for anchoring. At this time, the sur...

Embodiment 3

[0040] Parallel bar anchors using flexible sheet material (e.g. Image 6 The anchorage composed of 2, 3, and 4 in the anchorage), in which the number of rods in the anchorage is 2, and the sheet material wraps around the 2 rods in the anchorage to form a ring with a knot, and then the winding can be stopped ( figure 2 ), or continue to circle around (e.g. image 3 ), after installing and anchoring the sheets that have been self-locked around the rods and wound as above together with the anchors on the structural members, the embedding strips (or blocks) can be inserted between the two rods and anchored. Although a piece of sheet material passes between the two rods, it does not prevent the stretching of the sheet material to generate prestress by embedding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com