Method for lapping and anchoring fiber sheet around rod to reinforce structural component

A fiber sheet and reinforcement structure technology, which is applied in bridge reinforcement, building maintenance, bridge repair, etc., can solve the problem of unreliable conventional sticking effect of U-shaped fiber sheet, peeling and damage of fiber cloth end, and unreliable effect, etc. problems, and achieve the effect of overcoming the easy peeling off by force, improving the utilization rate of fiber strength, and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

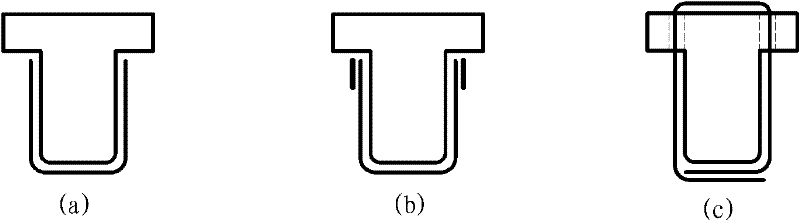

[0041] like Figure 5 As shown, the additional rod is pressed against the member by means of the fiber strips: the T-shaped cross-section beam is shear-reinforced, assuming that 5 fiber sheets are used, and the U-shape is attached to the bottom and two sides of the cross-section. In advance, cut out narrow grooves on both sides of the beam at the position where each fiber strip will pass through on the wing plate of the beam. The longitudinal dimension of a groove along the beam is slightly larger than the width of a fiber strip; the U-shaped fiber strips arranged at intervals After the two ends of the strip pass through the flange from bottom to top, bypass the additional longitudinal rod on the top of the beam, and then pass back from top to bottom through the groove, and roughly overlap with the inner fiber strip on the side of the beam (because the rod Both parts and grooves have a certain width, and the fiber strips cannot be completely superimposed at first, but the fibe...

Embodiment 2

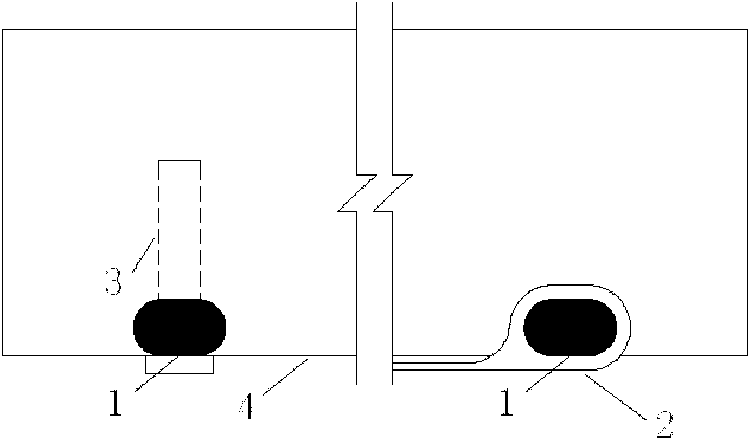

[0043] like figure 2 As shown, additional rods with holes are installed using rod-shaped inserts: For T-beams, box girders or rectangular beams that are not allowed to penetrate the flange, the longitudinal rods around which the U-shaped fiber sheets can be installed Angular parts. The horizontal rods for the longitudinal fiber sheets for flexural reinforcement usually must be installed on the top, bottom or side of the beam (slab) because there is no place to press against. Use additional rods with anchor holes, use rod-shaped inserts such as screws and rivets to pass through the anchor holes on the additional rods and then insert them into the pre-prepared holes on the component for anchoring, so that the additional rods are installed on the corresponding position on the component (such as figure 2 shown on the left). In order to make the fiber sheets after winding the rod stacked without spacing (such as figure 2 As shown on the right), you can chisel grooves in advan...

Embodiment 3

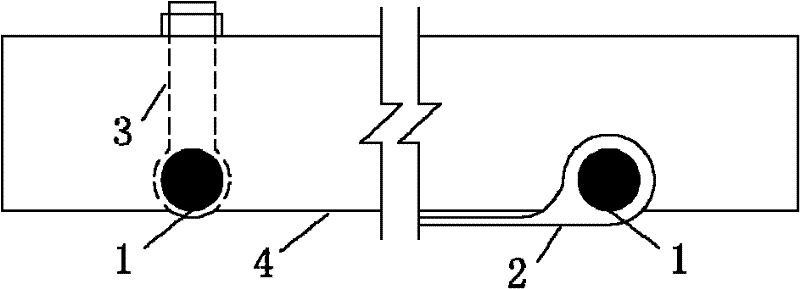

[0045] like image 3 , 4 As shown, the additional rods are installed with joint-shaped rods with holes: there are multiple joint-shaped rods with holes, and the holes of the joint-shaped rods with holes penetrate into the additional rods, and the joint-shaped rods with holes Scattered arrangement, requiring that the clear distance between two adjacent joint-shaped rods with holes is not less than the width of the fiber strip, and the shaft of the joint-shaped rod with holes is inserted into the pre-prepared hole on the component for anchoring, so Install additional rods at corresponding positions on the member (such as image 3 , 4 shown on the left). In order to make the fiber sheets after winding the rod stacked without spacing (such as image 3 , 4 As shown on the right), you can chisel grooves in advance where additional rods are required, and then glue the additional rods into place. image 3 The upper end of the joint-shaped rod with a hole is anchored by a nut. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com