Method for increasing well slots without stopping production on offshore petroleum platform

A technology for offshore oil and platforms, which is applied in the field of non-stop production of offshore oil platforms to increase well slots, and offshore oil platforms to increase well slots, which can solve the problems of not being able to maximize economic benefits, stop production of old offshore platforms, and low project cost The effect of improving production economic benefits, reducing offshore operation time, and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

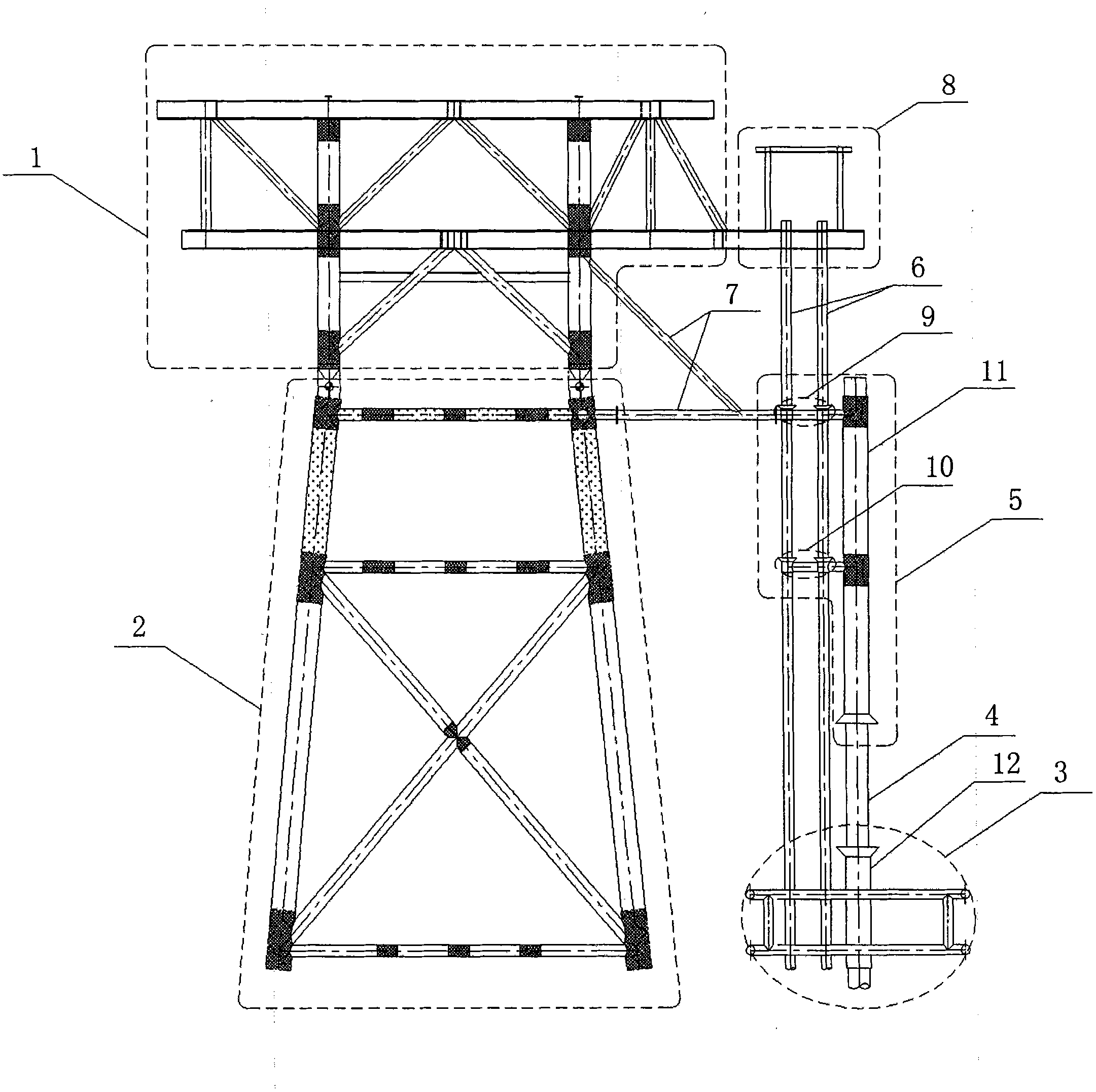

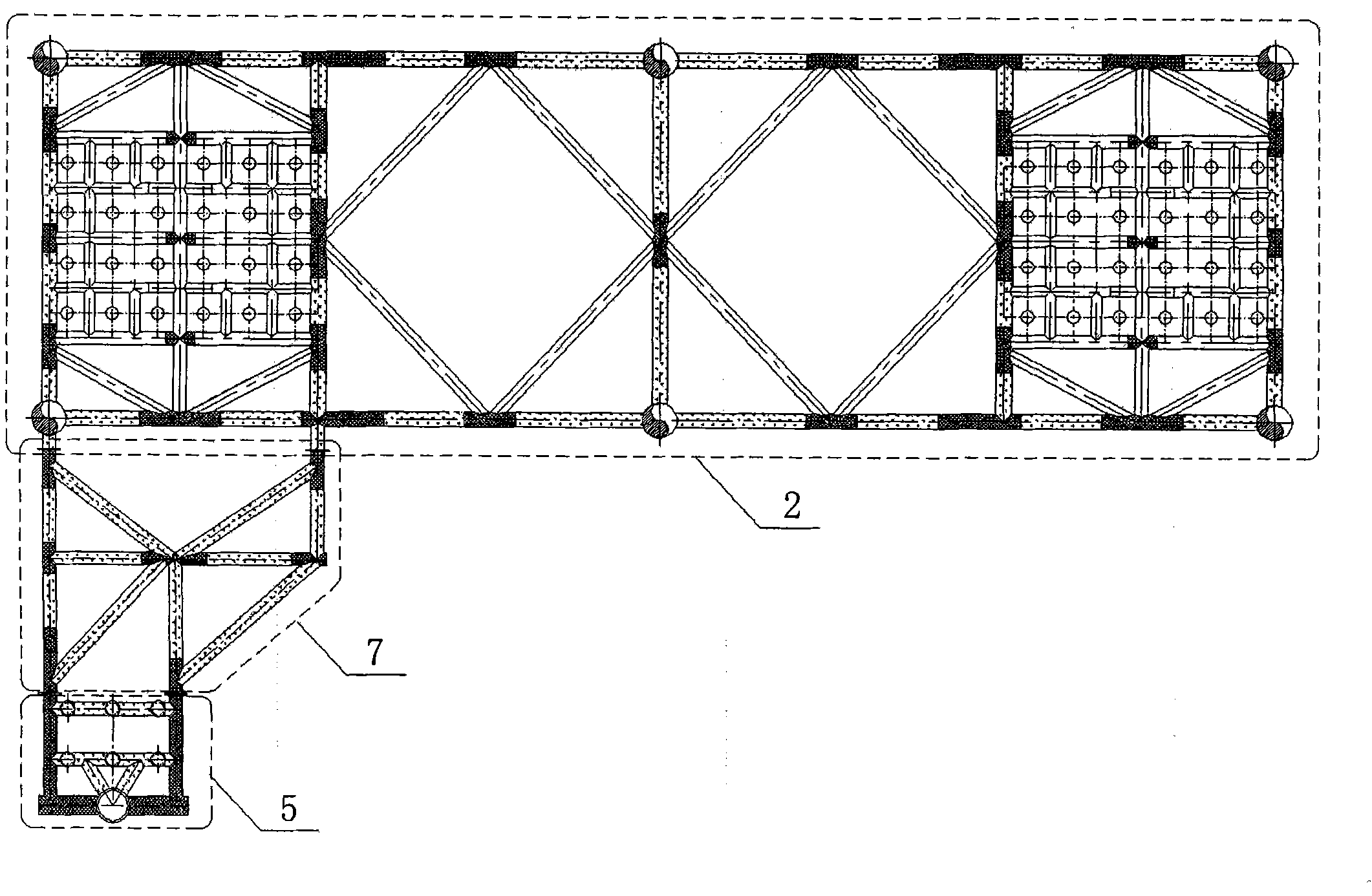

[0030] In order to simplify the installation process at sea, the main components such as the underwater base plate 3, the steel pile sleeve and the water riser casing guide structure 5, and the connecting structure 7 are prefabricated on land to form an integral structure, and then the These components are shipped offshore for installation.

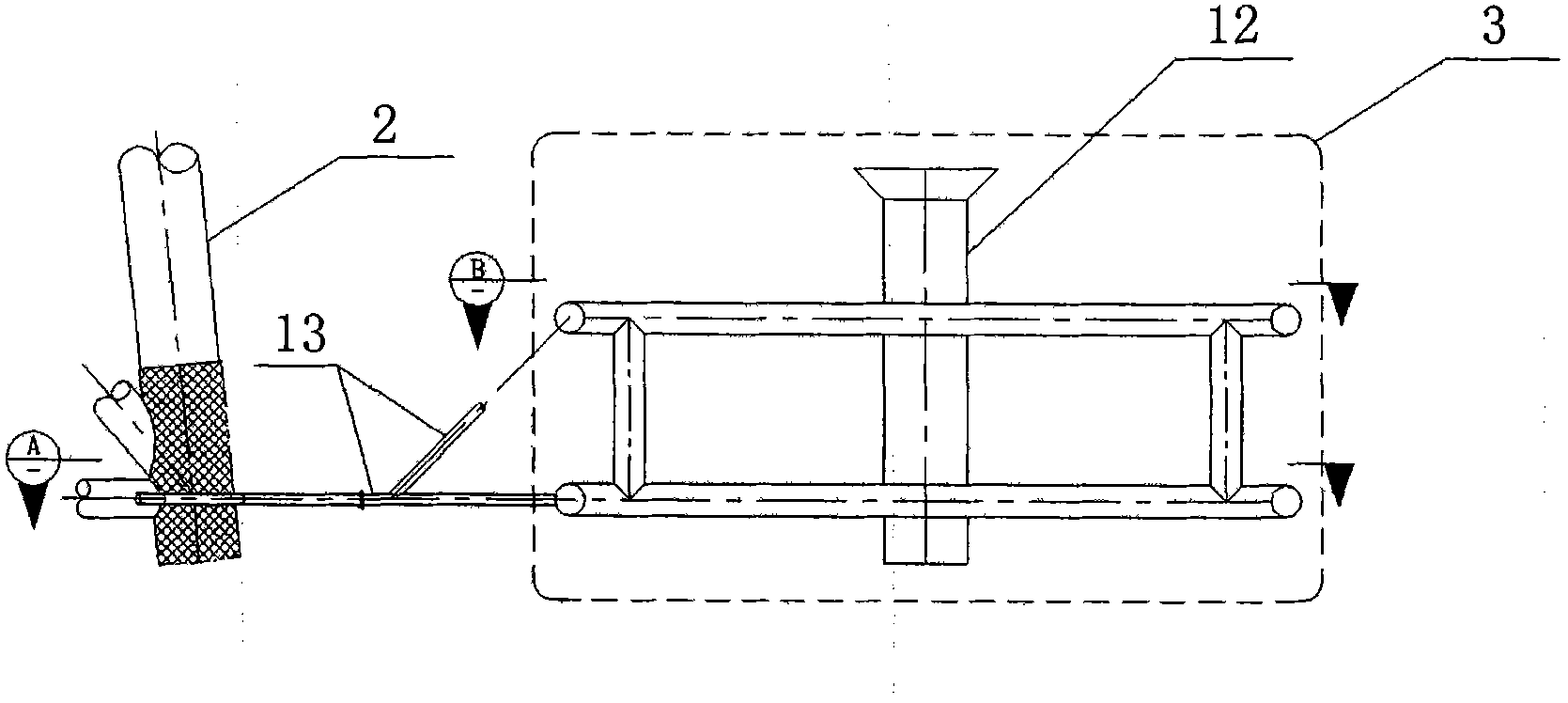

[0031] Such as Figure 3-Figure 6 As shown, the underwater base plate 3 is prefabricated and assembled into an integral frame structure by welding steel pipes. A steel pile guide 12 is installed in the middle of the frame structure, and a tentacle 13 is installed on the side by welding or bolt connection. The tentacle 13 is made of steel pipes. flat frame.

[0032] The connecting structure 7 is prefabricated and assembled into an integral flat sheet structure by welding the steel pipes.

[0033] Such as Figure 1-Figure 9 As shown, the structure installation of the present invention adopts the following steps:

[0034] (1), install th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com