Static seal device of bipyramid rotary dryer

A technology of rotary dryer and static sealing device, which is applied to the sealing of engines, non-progressive dryers, dryers, etc., can solve the problems of secondary pollution of materials, foreign matter pollution, large pollution, etc., to improve work efficiency and Effects of service life, yield improvement, and friction reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

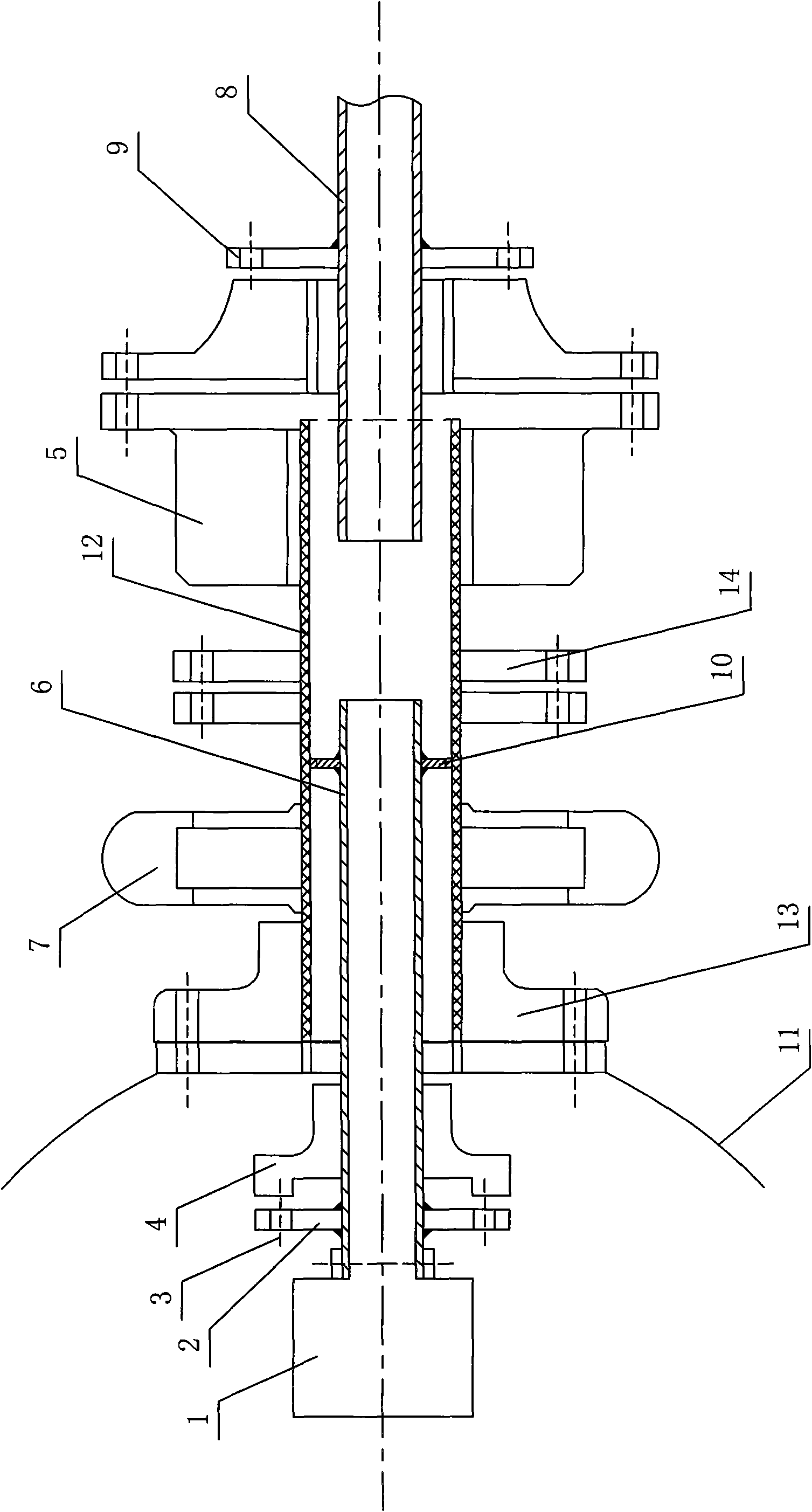

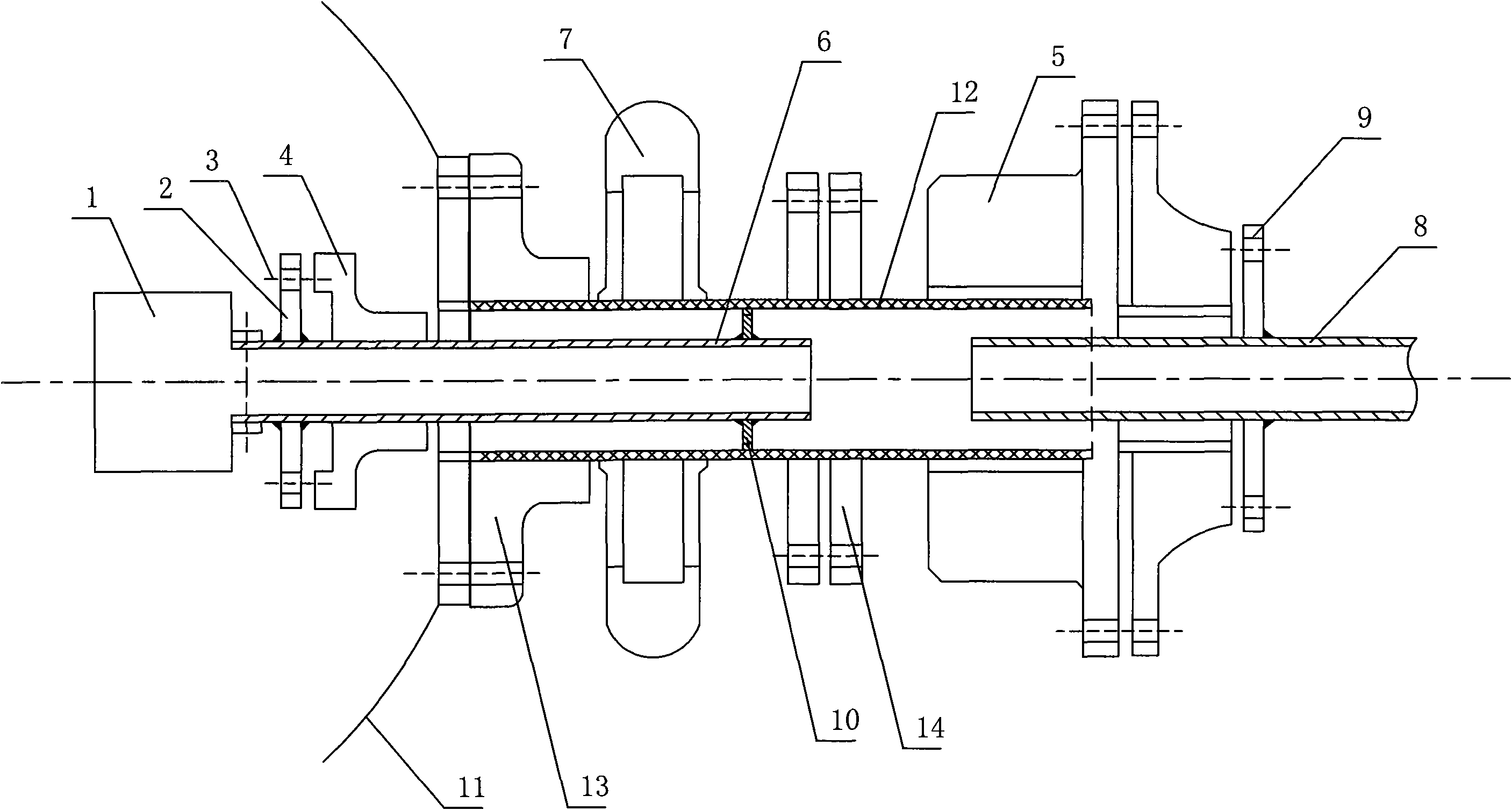

[0008] Such as figure 1 As shown, the static sealing device of the double-cone rotary dryer includes a conical tank body 11, and a vacuum bucket 1 is arranged inside the tank body 11. The mouth of the vacuum bucket 1 is connected to the first vacuum tube 6, and the outer end of the first vacuum tube 6 protrudes Tank 11. The first vacuum tube 6 between the vacuum bucket 1 and the tank body 11 is set with a fixed gland 2 and a fixed PTFE sleeve 4 for the tank body. The fixed gland 2 is welded on the outer periphery of the first vacuum tube 6, and the fixed gland 2 is connected to the tank body. The fixed tetrafluoro sleeve 4 is connected by the fixing bolt 3 .

[0009] One end of the first vacuum tube 6 protruding from the tank body 11 is inserted into the connecting tube 12 , and a sealing connector 10 is provided between the first vacuum tube 6 and the connecting tube 12 , and the sealing connector 10 is welded on the outer periphery of the first vacuum tube 6 .

[0010] One...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com