Polypropylene melt-blown sealant films for retort packaging

A retort-resistant, polypropylene homopolymer technology, applied in the field of heat-sealing film and gusset packaging bags, can solve the problems of insufficient sealing strength and insufficient adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

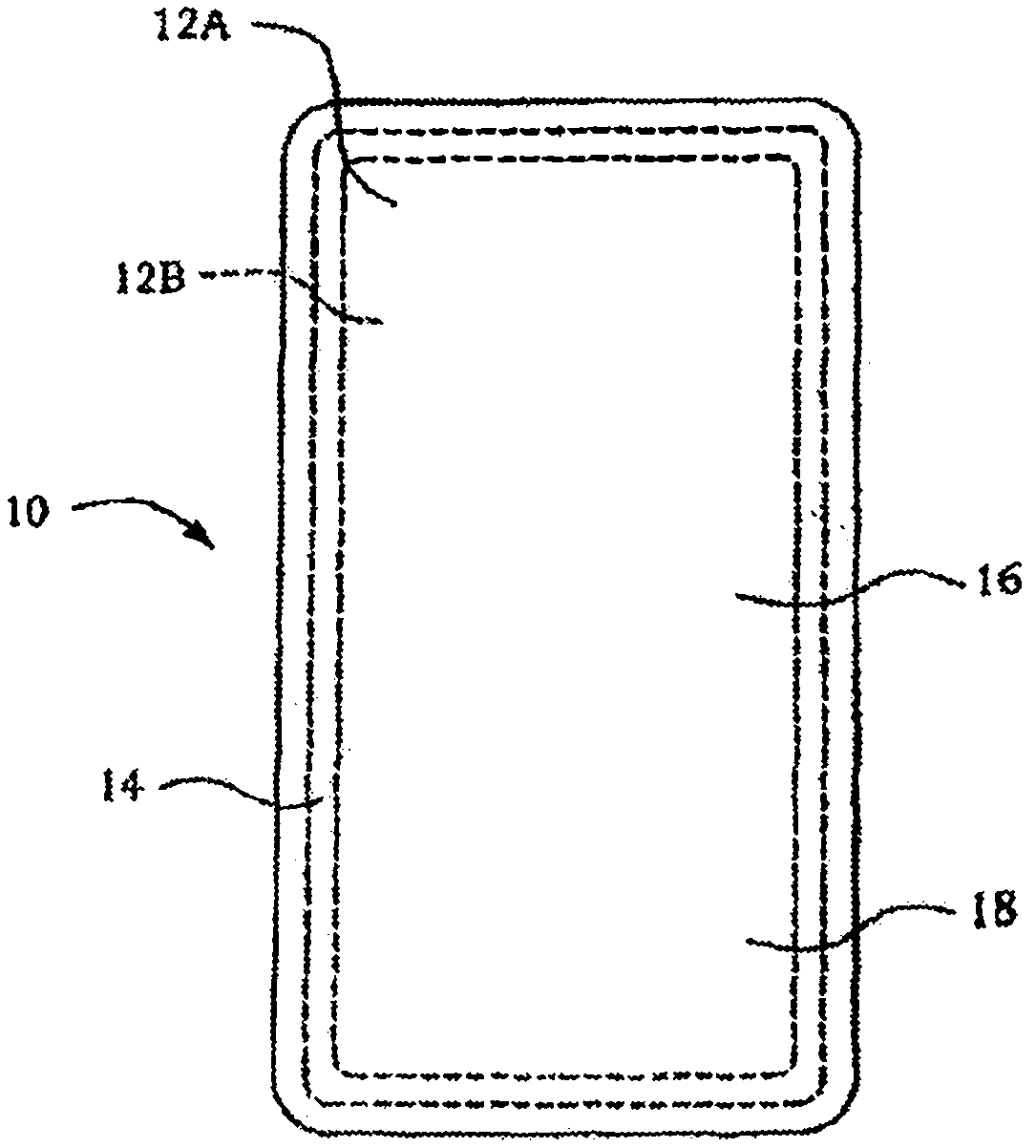

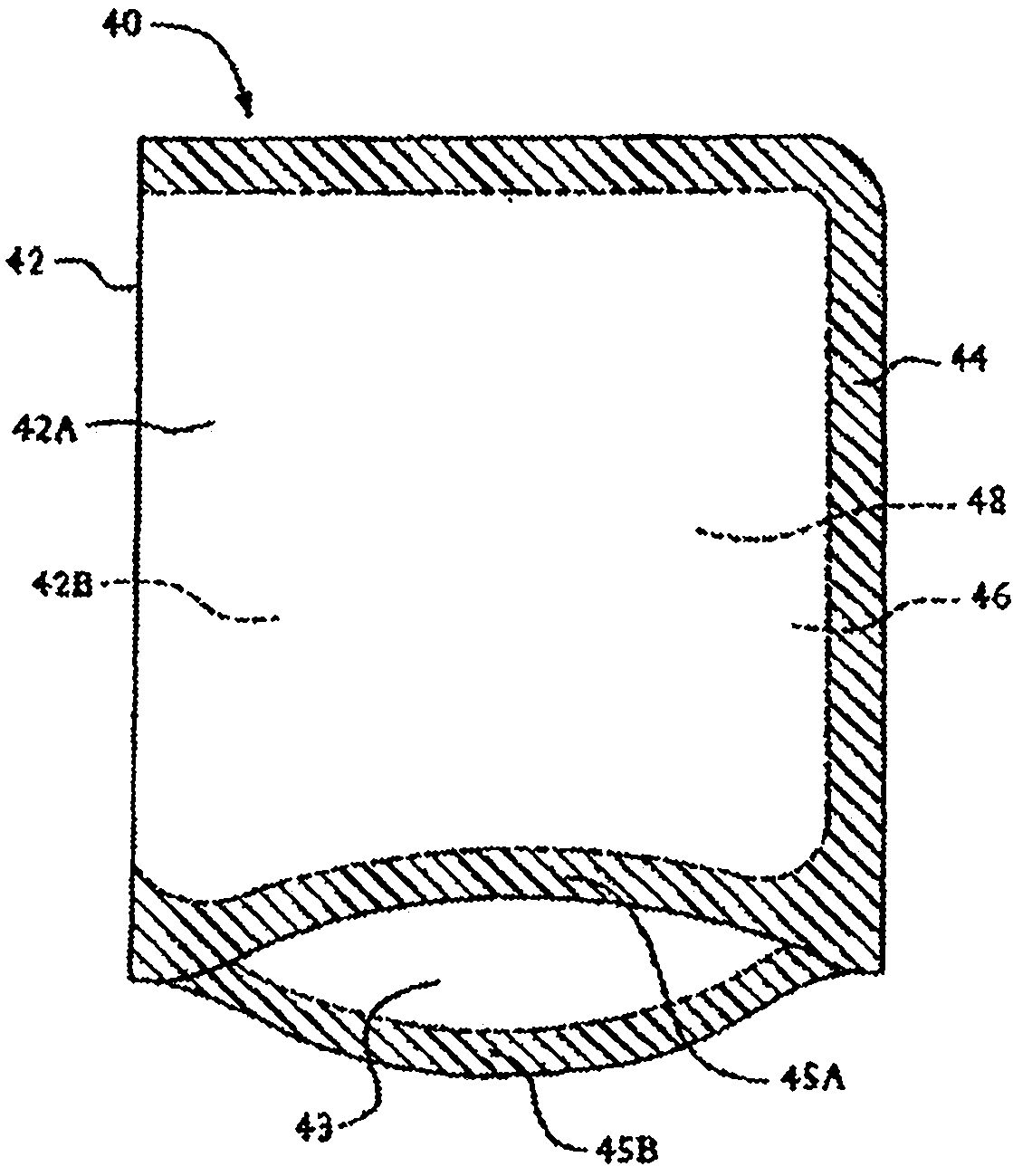

Image

Examples

Embodiment 1

[0099]A coupled impact propylene copolymer is made by reacting C 104-01 with a coupling agent. C 104-01 is a medium impact propylene copolymer available from The Dow Chemical Company. C104-01 has a density of 0.900 g / cc, a melt flow rate of 1.2 g / 10 minutes, about 3 to about 12 wt. % of units derived from ethylene, and a tensile modulus of 167,000 p.s.i. (according to ISO 527-2). The coupling agent is diphenyloxide bissulfonate azide ("DPO-BSA"). The DPO-BSA is a molecular melt with 23.8% by weight DPO-BSA, as described in Table 2 below.

[0100] Table 2

[0101] DPO / BSA (diphenyl ether bissulfonyl azide): (N 3 SO 2 ) 2 C 6 h 6

[0102] Molecular melt: 23.8 wt% DPO / BSA

[0103] Sulfur content in molecular melt: 0.238*0.1684=0.0400

[0104]

[0105] C 104-01 has a continuous phase of polypropylene homopolymer in which is dispersed an ethylene-propylene copolymer elastomeric phase. The ethylene-propylene copolymer comprises 50% by weight of monomer units derived ...

Embodiment 2

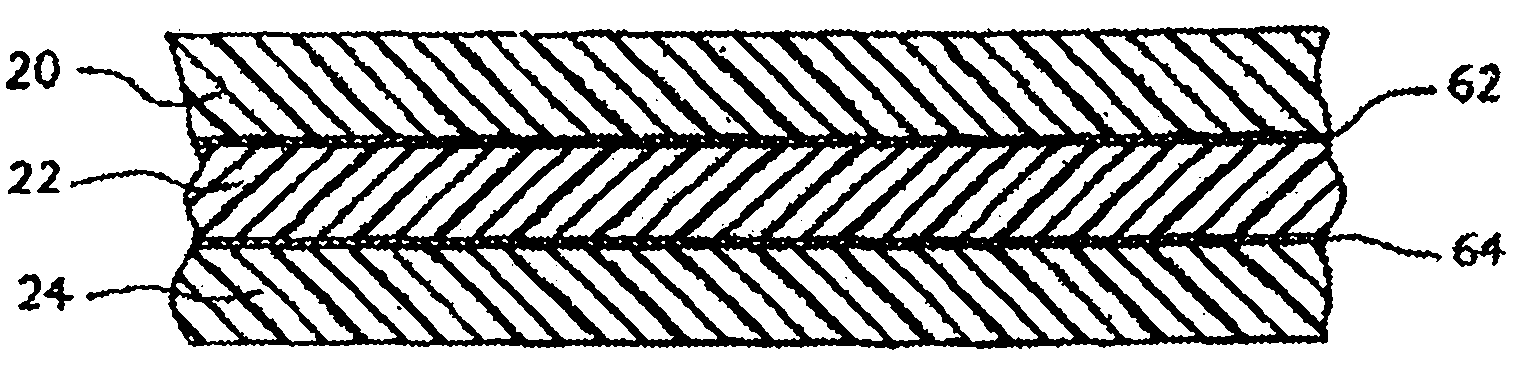

[0124] A sealant layer having a multilayer structure is provided. By introducing VERSIFY TM Coextrusion of 2000 plastomers and CIPC-1 resins into multilayer coextruded blown film structures to produce sealant films. The multilayer structure can have the following forms: A / B / A, B / B / A, or B / A / A. When the structure includes multiple A layers, the thickness of each A layer may be the same or different. Similarly, when the structure includes multiple B layers, each B layer may have the same or different thickness. The composition of Layer A and the composition of Layer B are provided below.

[0125] Layer A VERSIFY TM 2000 Plastomer

[0126] Tier B CIPC-1 or

[0127] 70%CIPC-1+30%VERSIFY TM 2000 Plastomer

[0128] Two examples of A / B / A coextruded blown film structures are shown in Table 5. Both examples provide high retort temperature resistance and excellent blown film processability through the use of a high melt strength, high temperature resistant CIPC-1 core layer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The melt flow rate | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com