Transformer core having a stray field shield

A technology for shielding devices and transformers, applied to parts of transformers/inductors, preventing/reducing unwanted electric/magnetic influences, electrical components, etc., to achieve the effects of improving technical reliability, small copper volume, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

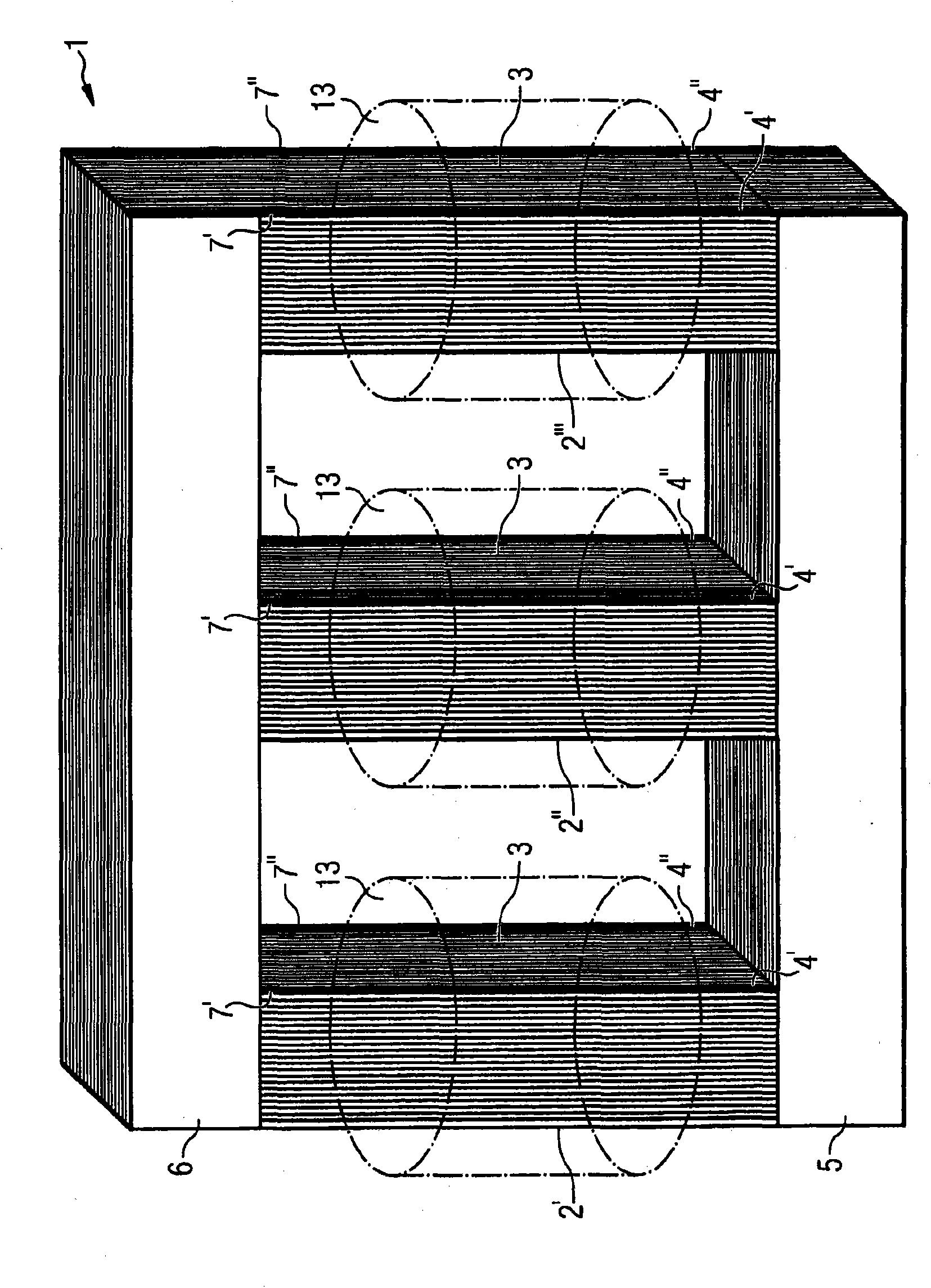

[0024] figure 1 The perspective view of FIG. 2 shows in diagram form a three-leg transformer known per se, the magnetic core 1 of which is made of sheet metal. The magnetic core 1 basically consists of three magnetic core legs 2 ′, 2 ″, 2 ′″, a lower yoke 5 and an upper yoke 6 . Each of the magnetic core legs 2', 2", 2'" carries a winding arrangement 13 which is figure 1 Indicated by the dotted line.

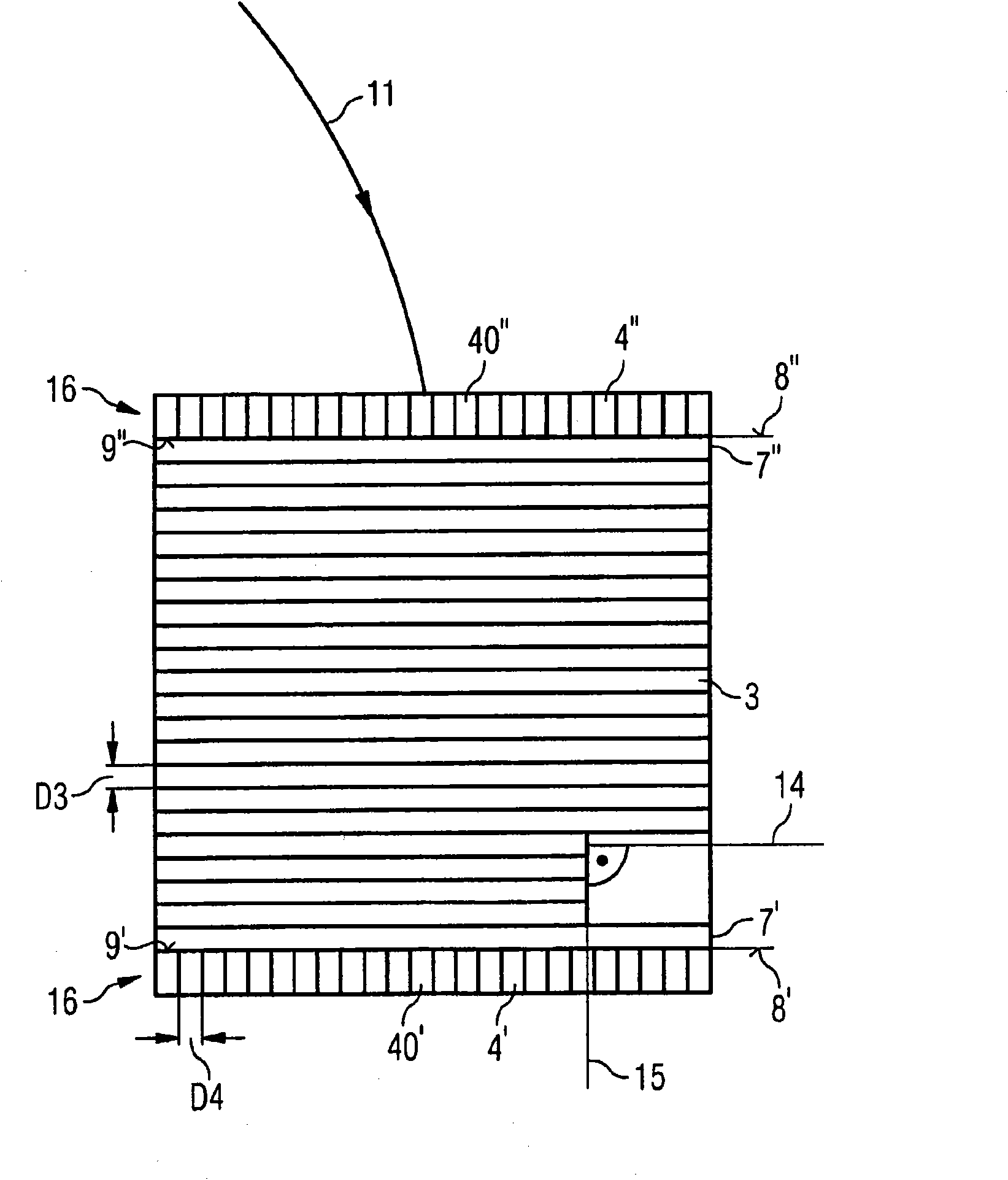

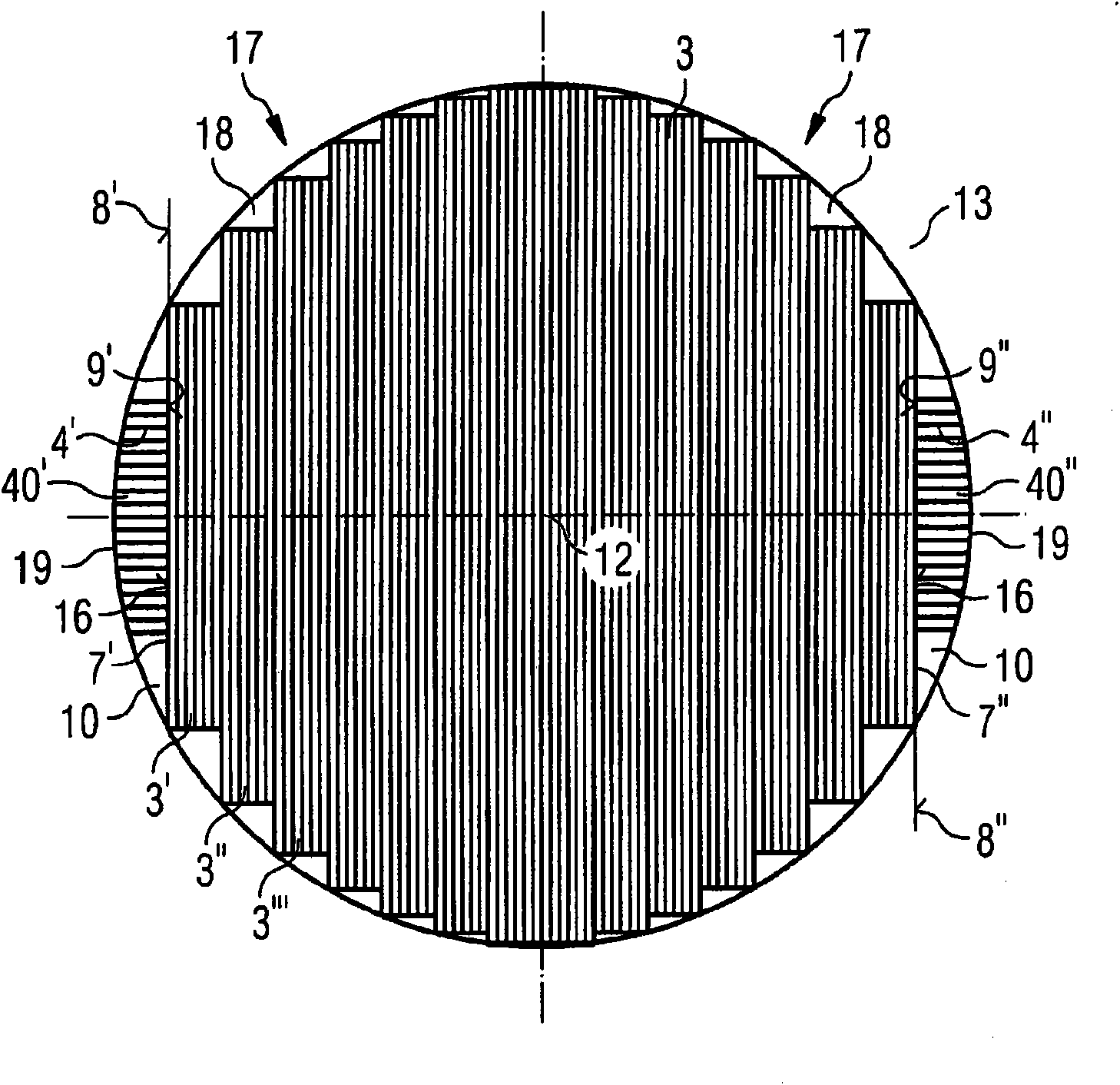

[0025] as from figure 1 As can also be seen in the spatial diagram of , each of the magnetic core legs 2', 2", 2'" is respectively composed of (magnetic core leg) laminations 3 and two additional laminations 4' and 4". As described in further detail below, the laminations 4', 4" act as leakage field shields. Viewed in the stacking direction, the laminated core 3 is closed at the end side by the end laminations 7', 7". figure 1 The front lamination group 4' abuts against the front end sheet layer 7' of the lamination group 3, and the rear lamination group 4" abuts agains...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com