High-precision speed measurement positioning method and system for medium and low-speed maglev trains

A technology of maglev train and positioning method, which is applied in the direction of speed/acceleration/impact measurement, measuring device, and using a device that measures the time required to move a certain distance, which can solve the adverse effects of speed measurement and positioning accuracy, uneven sleeper distance, and accumulated errors. and other problems, to achieve the effect of improving anti-interference ability, low cost and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

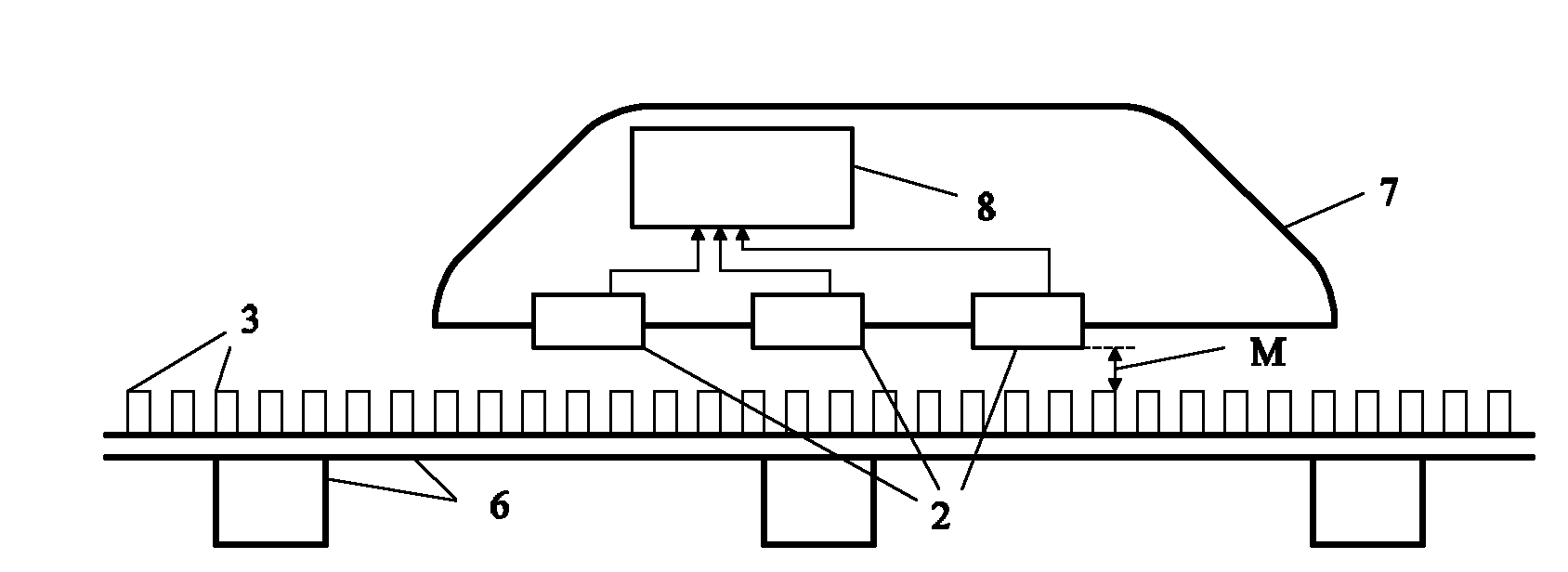

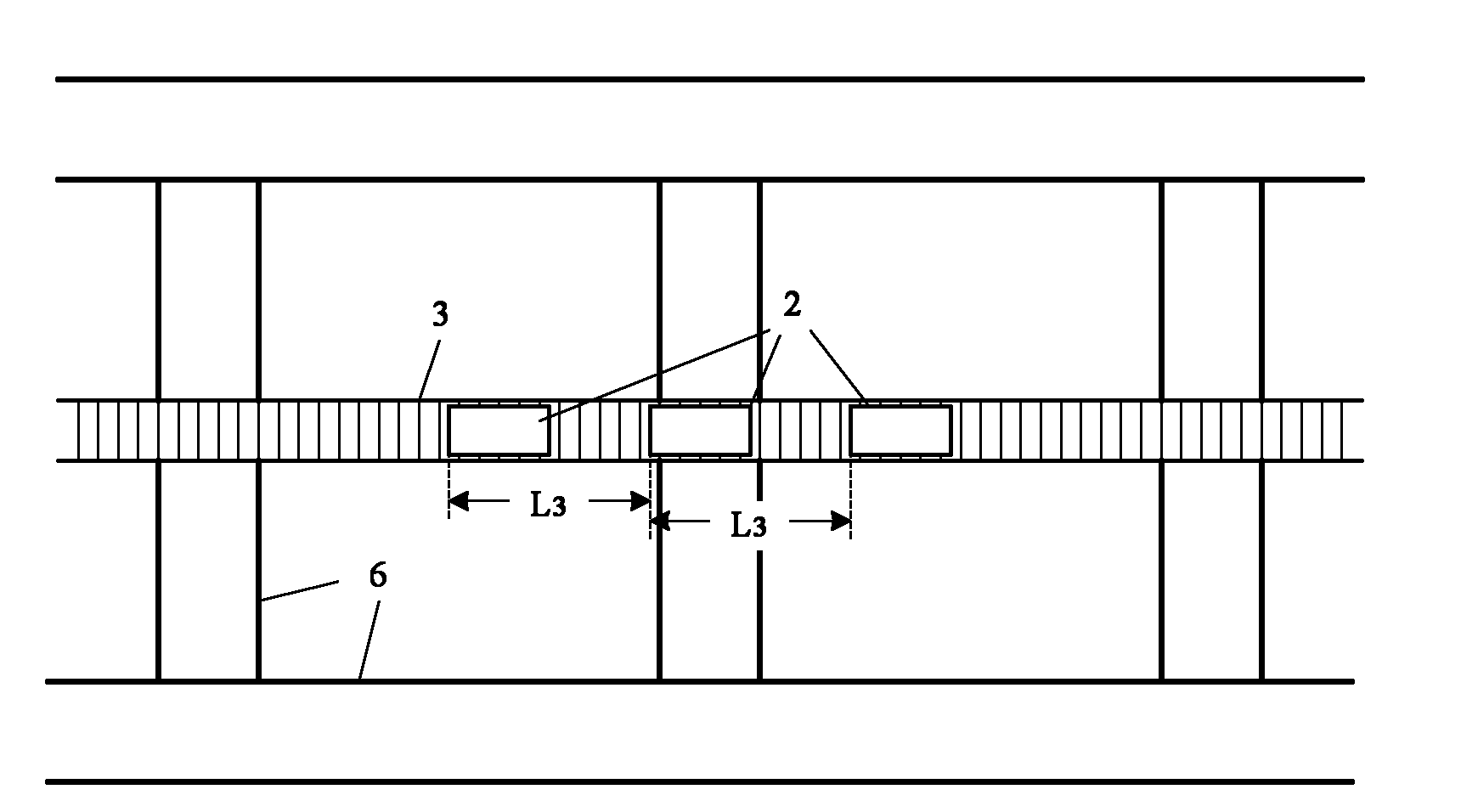

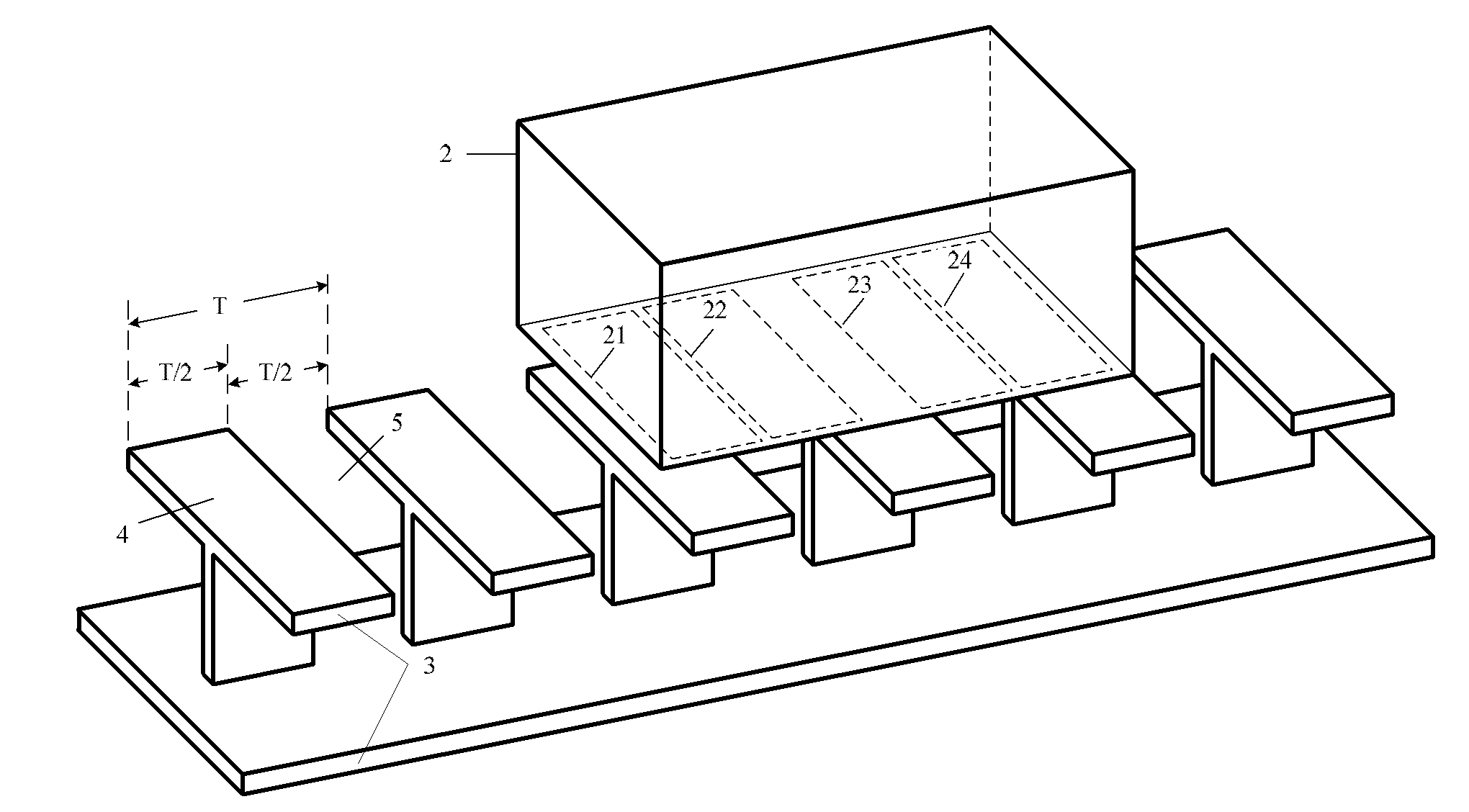

[0042] Such as figure 1 and figure 2As shown, the high-precision speed measurement and positioning method and system for medium and low-speed maglev trains of the present invention include metal splines 3 fixed on the track 6, more than one speed measurement and positioning sensors 2 installed on the car body 7, and a signal processing unit, The signal processing unit adopts a host computer, and when the speed measurement positioning sensor 2 and the metal tooth groove bar 3 are close together, a periodic on-off signal is generated and sent to the signal processing unit, and the signal processing unit judges the speed and Location. The specific installation quantity of the speed measuring and positioning sensors 2 shall be determined according to the specific measurement accuracy requirements and the length of the cogging period T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com