Method for treating and recycling hot-rolling high-oil-containing waste water in iron and steel plant

A technology for wastewater treatment and iron and steel plants, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as lack of technical routes, destruction of water balance in iron and steel plants, environmental pollution, etc. , to achieve the effect of saving water resources, good economic and social benefits, and protecting the water environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

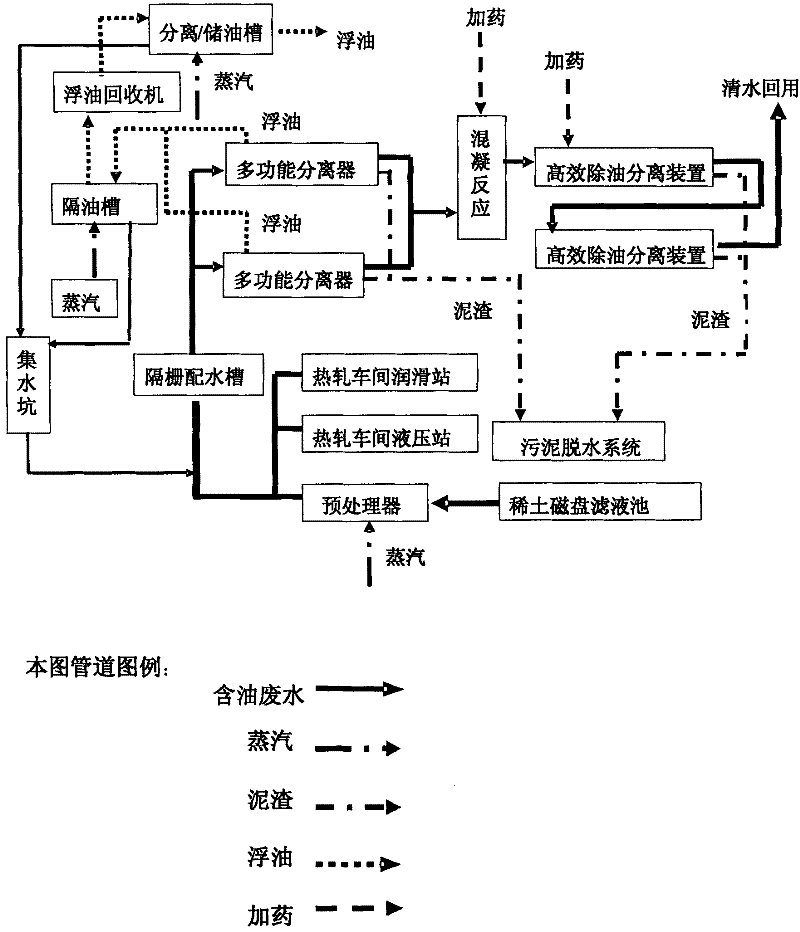

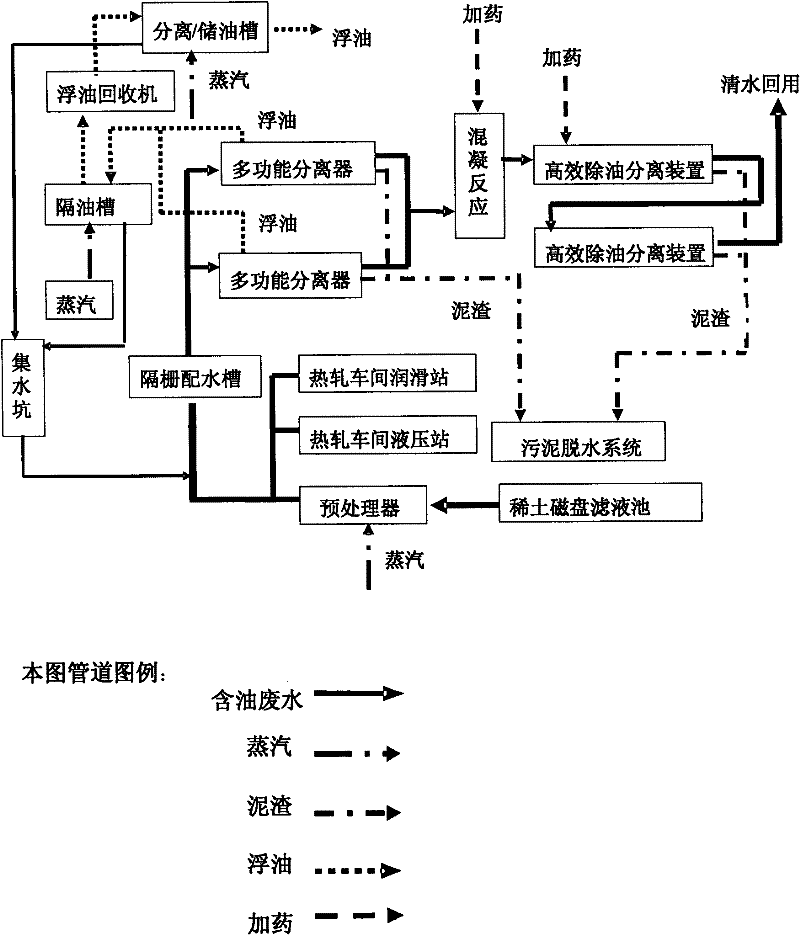

[0017] The filtrate water (oil content is usually 500-2000mg / L, suspended matter 100-500mg / L) produced by the rare earth disk device in the water treatment area first enters the preprocessor, and then is discharged together with the hydraulic station and lubrication station of the hot rolling workshop The oily wastewater (oil content is usually 200mg / L) is uniformly sent to the grille and water distribution tank, and after removing the larger impurities in the wastewater through the grille, it enters the multifunctional oil residue separator. Two multifunctional oil residue separators The separator alternates water inlet, net sink, water outlet and slag discharge in time sequence.

[0018] The multifunctional oil residue separator mainly has three functions. One is to adjust the water quantity and quality of oily wastewater; the other is to collect the floating oil on the upper part of the separator and flow it to the oil trap; the third is to scrape off the settled sludge and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com