Manufacturing method of jack electrical connector

A technology for electrical connectors and manufacturing methods, which is applied in the directions of contact manufacturing, connection, and components of connecting devices, can solve the problems of small contact area, reduced elasticity, and large heat generation, and achieves large contact area and long-lasting bonding force. Stable, low pressure drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

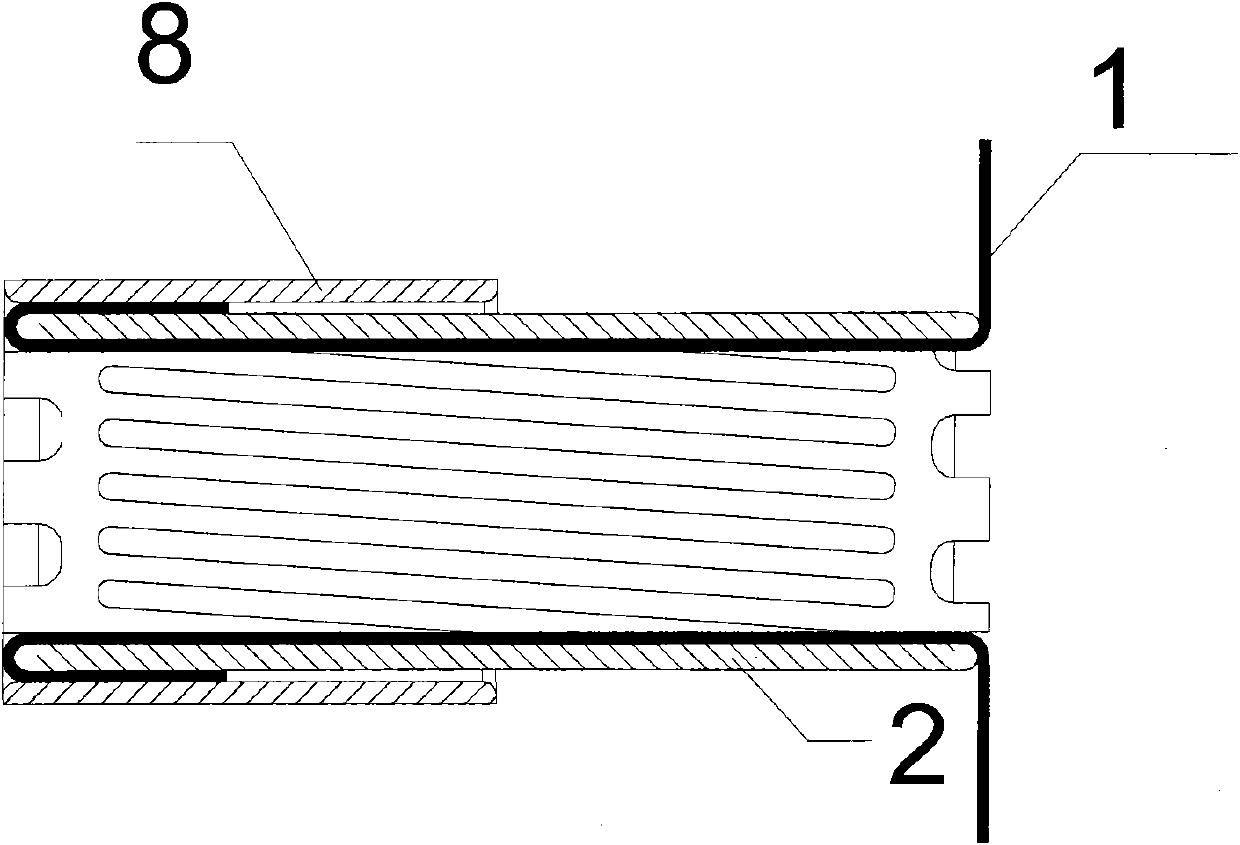

[0035] Such as Figure 5 As shown, the specific embodiment of the jack electrical connector of the present invention includes an elastic conductive reed roll 1, a conductive inner sleeve 2 and a conductive outer sleeve 3, and an elastic conductive reed roll 1, a conductive inner sleeve 2 and a conductive outer sleeve 3. The sections are all circular.

[0036] This particular embodiment is made and assembled like this:

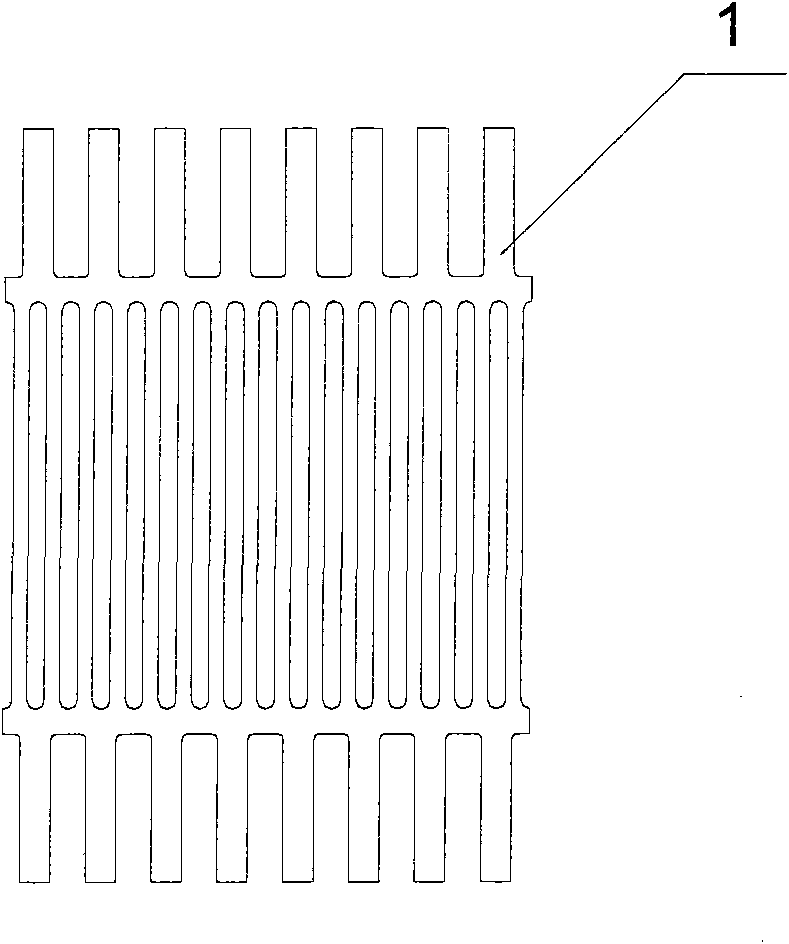

[0037] 1. Use a stamping die to process the copper strip and process it into a grid reed with a shape such as figure 1 shown;

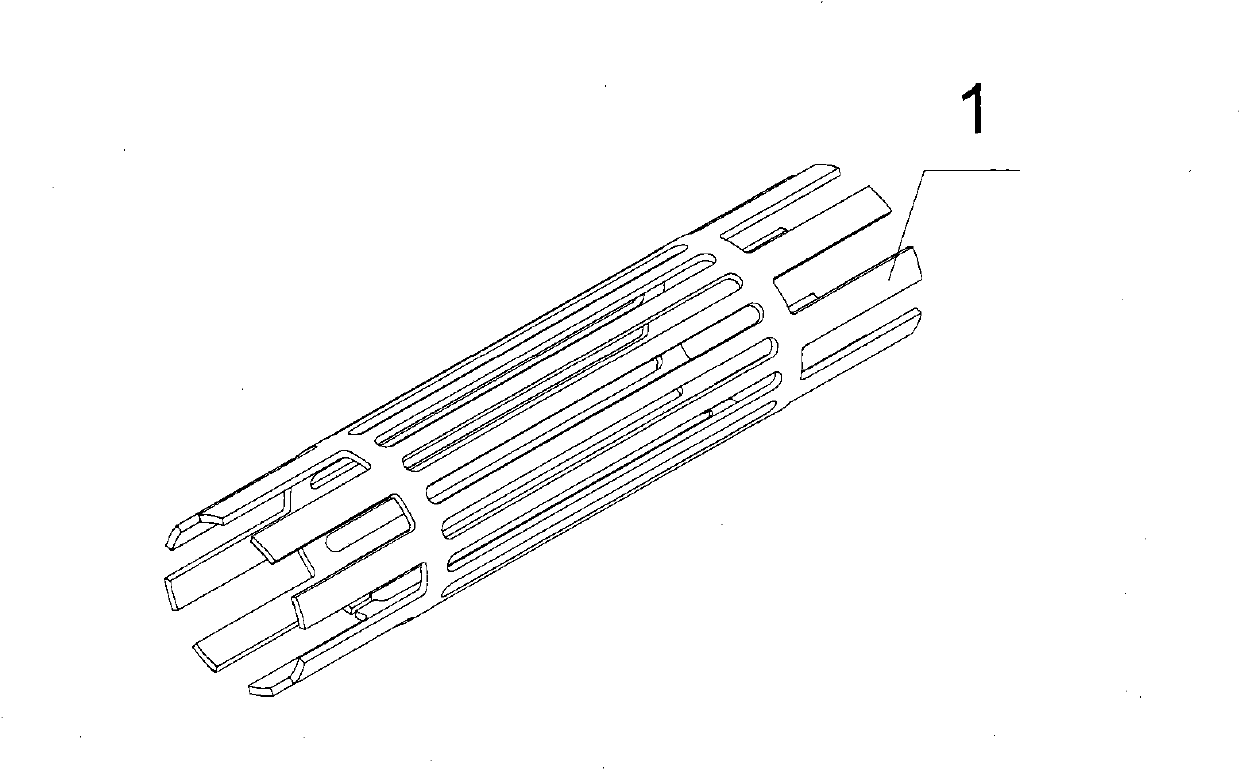

[0038] 2. Manually / using tools to roll the stamped and formed reed to form an elastic conductive reed roll 1, the shape is as follows figure 2 shown;

[0039] 3. Put the elastic conductive reed roll 1 into the conductive inner sleeve 2;

[0040] 4. Manually / use tools to expand and deform the protruding end of the conductive reed roll 1 protruding outside the conductive inner sleeve 2. The expansion and deformation are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com