Volume type gas compressor

A gas compressor, volumetric technology, applied in the direction of liquid fuel engines, mechanical equipment, machines/engines, etc., can solve the problem that bearing lubrication cannot be performed, volumetric gas compressors cannot use oil-free gas compressors, and housings cannot be maintained Problems such as the gap with the screw rotor to achieve the effect of preventing gas leakage and efficient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

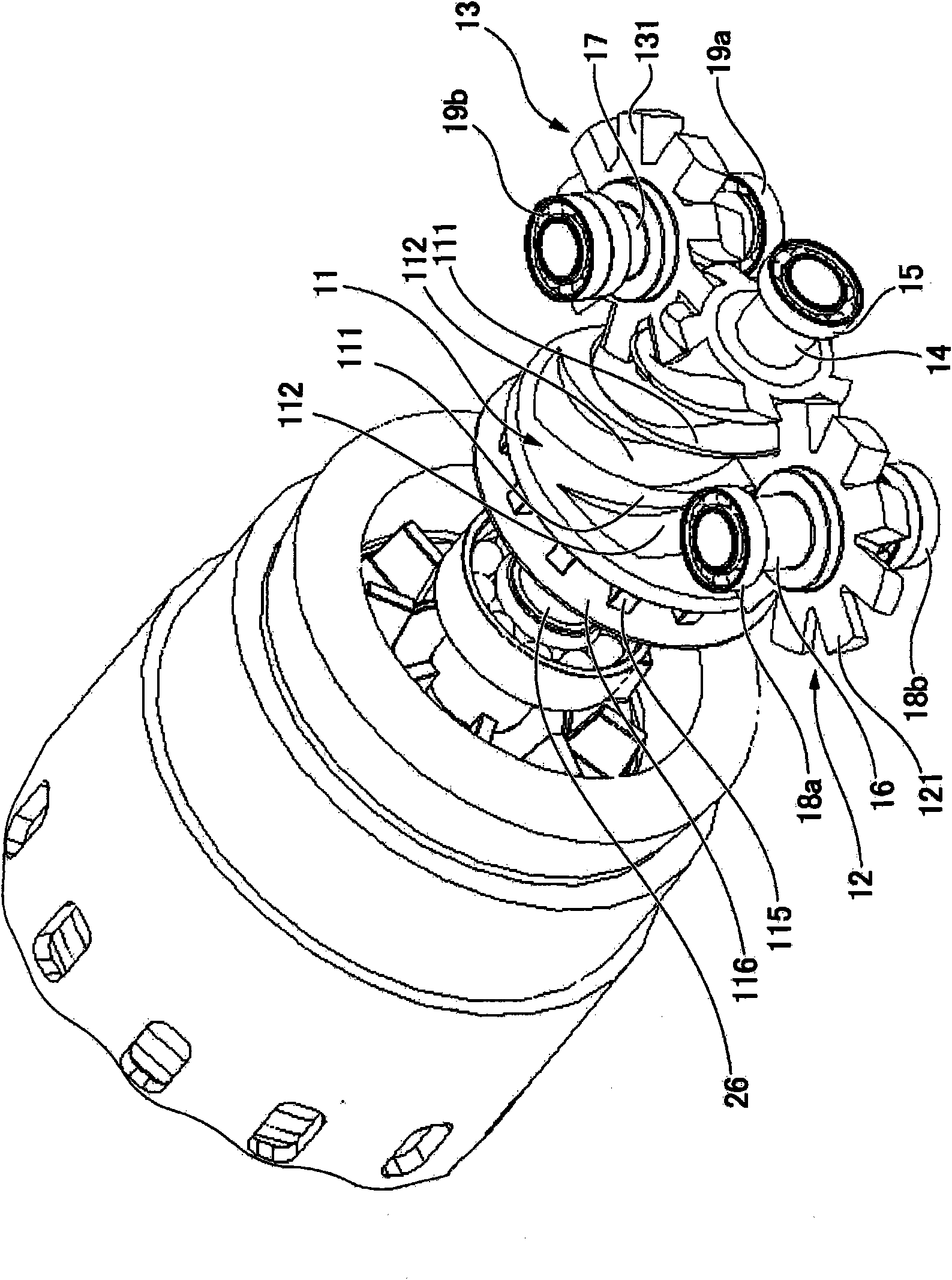

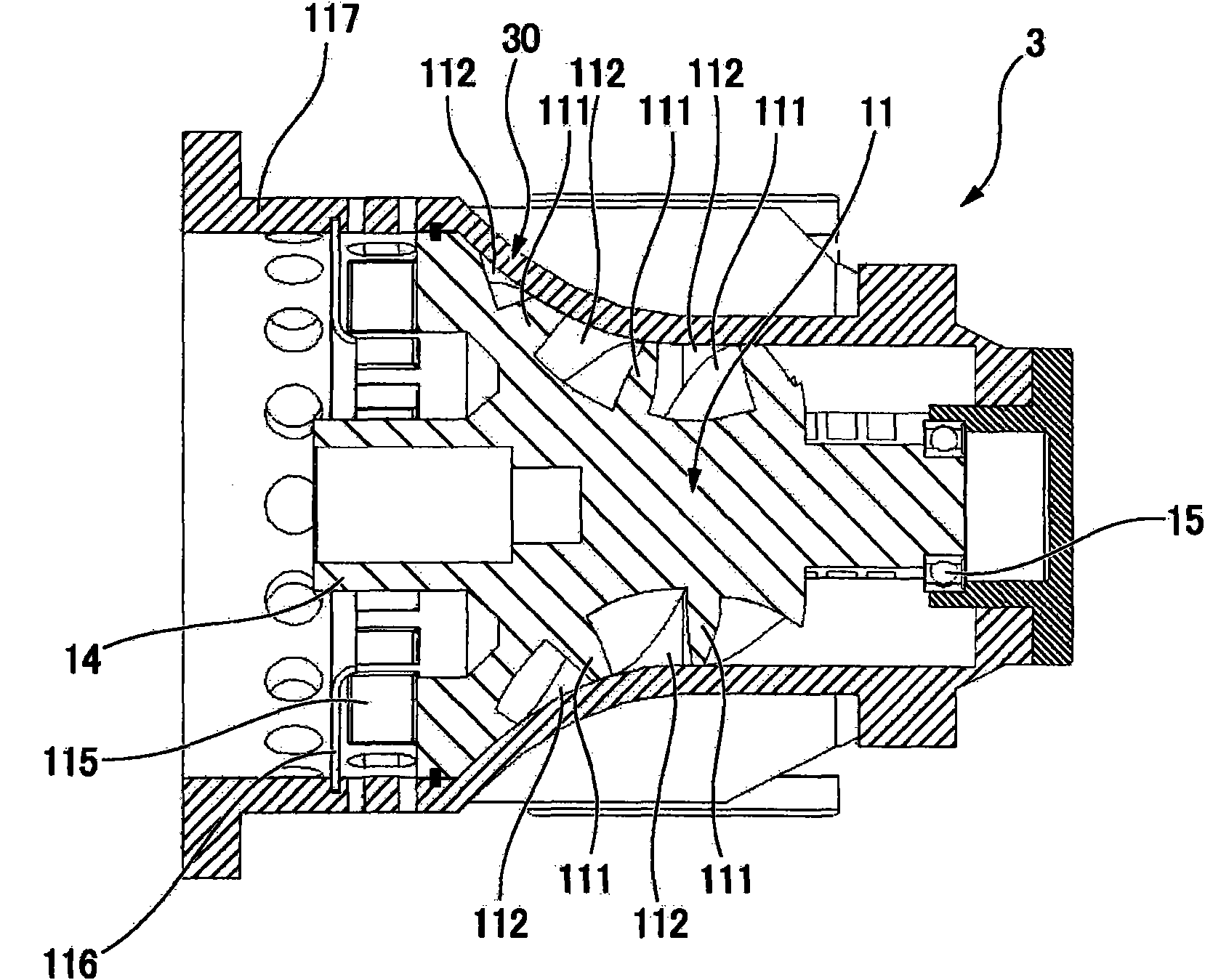

[0043] Hereinafter, an embodiment of a two-stage gas compression device to which the present invention is applied will be described with reference to the drawings.

[0044] (the whole frame)

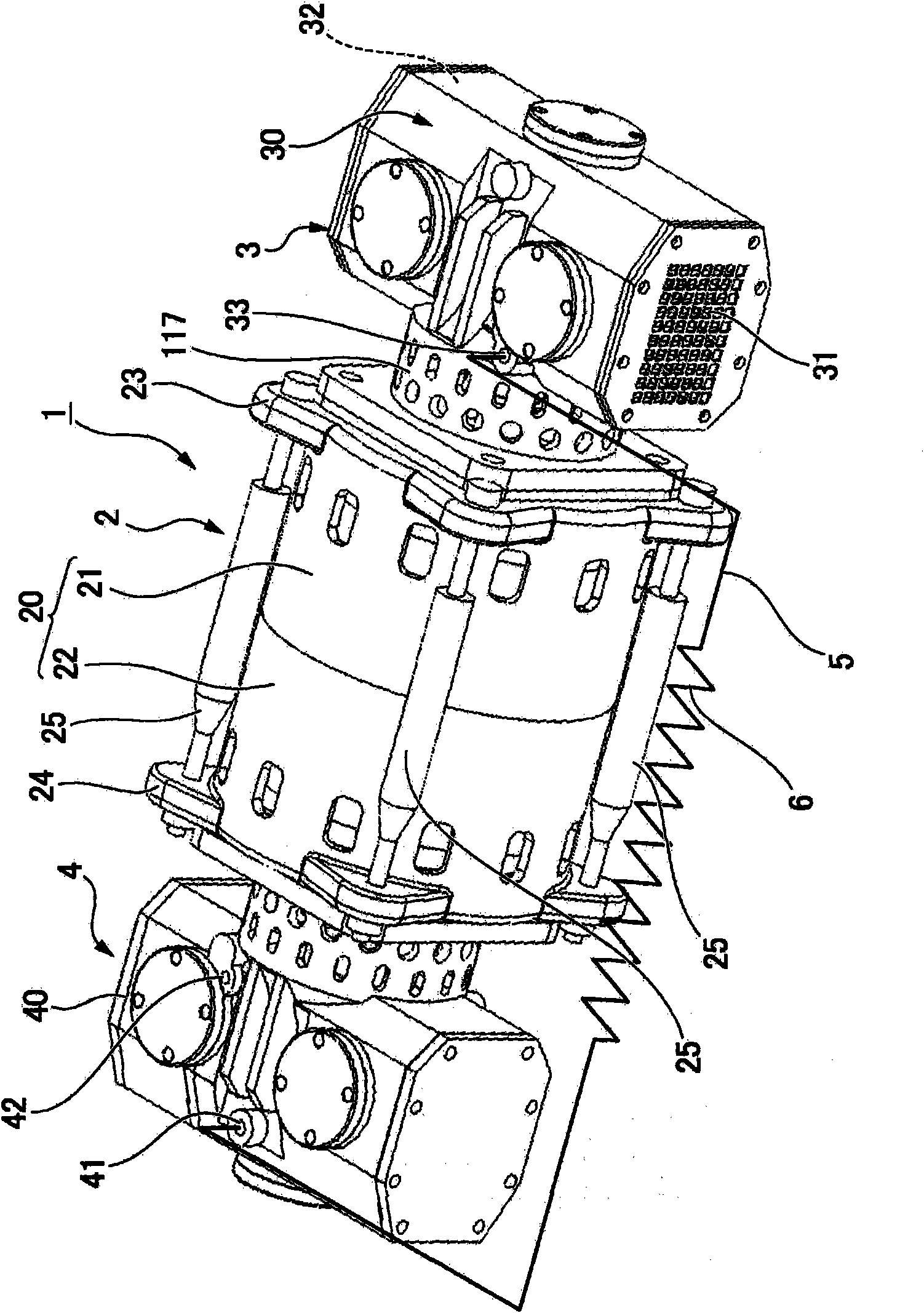

[0045] figure 1It is a perspective view showing the appearance of a two-stage gas compression device to which the present invention is applied. The two-stage gas compression device 1 includes: a twin-shaft motor 2; a front-stage gas compressor unit 3 and a rear-stage gas compressor unit 4 connected to both sides of the twin-shaft motor 2 in a coaxial state; A discharge pipe 5 for supplying gas compressed by the compressor unit 3 to the subsequent gas compressor unit 4 ; and an intercooler 6 for cooling the compressed gas passing through the discharge pipe 5 . The front-stage gas compressor unit 3 and the rear-stage gas compressor unit 4 are air-cooled volumetric oil-free screw gas compressors.

[0046] The motor case 20 of the biaxial motor 2 is composed of a front-stage motor case 21...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap