Clear soup hotpot seasoning and preparation method thereof

A technology of hot pot bottom material and clear soup, which is applied in the field of food seasoning, can solve the problem of bad taste of clear soup hot pot bottom material, etc., and achieve the effect of health care value, unique process and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

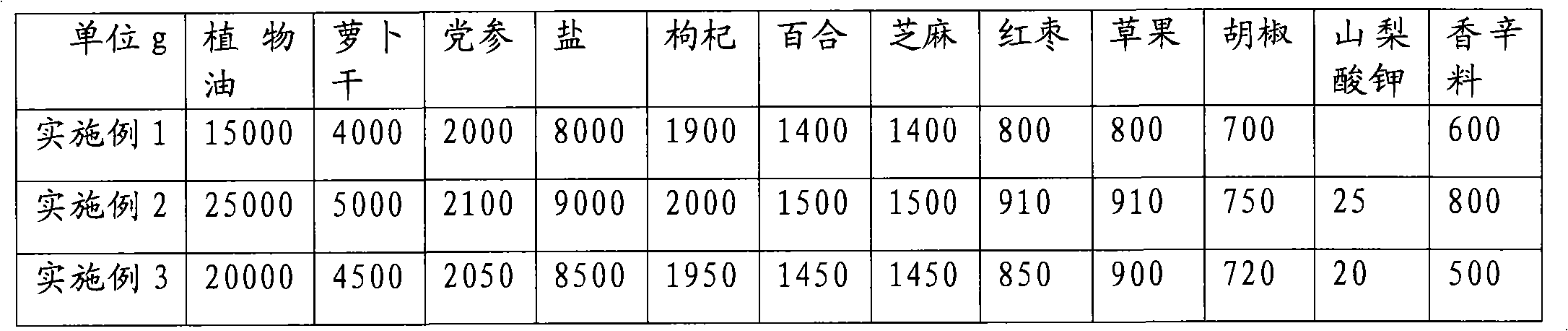

Embodiment 1

[0045] 1. Material selection: choose Codonopsis pilosula, wolfberry, lily, sesame, red dates, grass fruit, pepper and dried radish with a water content of 10%, and require no impurities and no mildew.

[0046] 2. Blanching: In order to fully ensure the sensory quality of dried radish products, 4000g of dried radish after washing must be blanched in warm water at 100°C for 30mim.

[0047] 3. Stir-frying: Add 15000g soybean oil into the automatic cooking pot, boil the oil with high heat and cook at a temperature of 120°C to remove the smell of raw oil. After adding 600g of spices, put the segmented dried radish into the oil, continuously Stir and fry for about 15 minutes.

[0048] 4. Add Codonopsis 2000g, salt 8000g, wolfberry 1900g, lily 1400g, sesame 1400g, red dates 800g, Tsaoguo 800g, pepper 700g and 10% water After being heated to 100°C for 20 minutes, cease fire, sterilize, and pack into a pot, it becomes the hot pot bottom material of the present invention.

Embodiment 2

[0050] 1. Material selection: choose Codonopsis pilosula, wolfberry, lily, sesame, red dates, grass fruit, pepper and dried radish with a water content of 5%, and require no impurities and no mildew.

[0051] 2. Blanching: In order to fully ensure the sensory quality of dried radish products, 5000g of dried radish after washing must be blanched in warm water at 100°C for 40mim.

[0052] 3. Stir-frying: Add 25000g of vegetable oil into the automatic cooking pot, boil the oil with high heat and cook at a temperature of 120°C to remove the smell of raw oil. After adding 800g of spices, put the segmented dried radish into the oil and keep stirring , fry for 25 minutes.

[0053] 4. Add Codonopsis 2100g, salt 9000g, wolfberry 2000g, lily 1500g, sesame 1500g, red dates 910g, Tsaoguo 910g, pepper 750g, potassium sorbate 25g and total The water of 10% by weight is heated to 100 DEG C and continues for 30 minutes, and after cease-fire, it becomes the chafing dish bottom material of the...

Embodiment 3

[0055] 1. Material selection: choose Codonopsis pilosula, wolfberry, lily, sesame, red dates, grass fruit, pepper and dried radish with a water content of 11%. It is required to be free of impurities and mildew.

[0056] 2. Blanching: In order to fully ensure the sensory quality of dried radish products, 4500g of dried radish after washing must be blanched in warm water at 100°C for 35mim.

[0057] 3. Stir-frying: Add 20000g vegetable oil into the automatic cooking pot, boil the oil at high heat and cook at a temperature of 120°C to remove the smell of raw oil, add 500g of spices (scallion, ginger, garlic in total) and dry the segmented radish Add to the oil, stirring constantly, and fry for 20 minutes.

[0058] 4. Add Codonopsis 2050g, salt 8500g, wolfberry 1950g, lily 1450g, sesame 1450g, red dates 850g, Tsaoguo 900g, pepper 720g, potassium sorbate 20g and total 10% by weight of water is heated to 100 DEG C for 25 minutes, sterilized after cease-fire, and canned is the chaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com