Method for molding and manufacturing integrated shoe body of foot protection sport shoe

A manufacturing method and an integrated technology, applied to household components, household appliances, and other household appliances, etc., can solve problems such as the easy damage of the joint part of the shoe body and the sole, and the production cost of the joint part is too long, so as to reduce the production time and manpower Operating cost, improving the structural strength of the shoe body, and improving the effect of impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

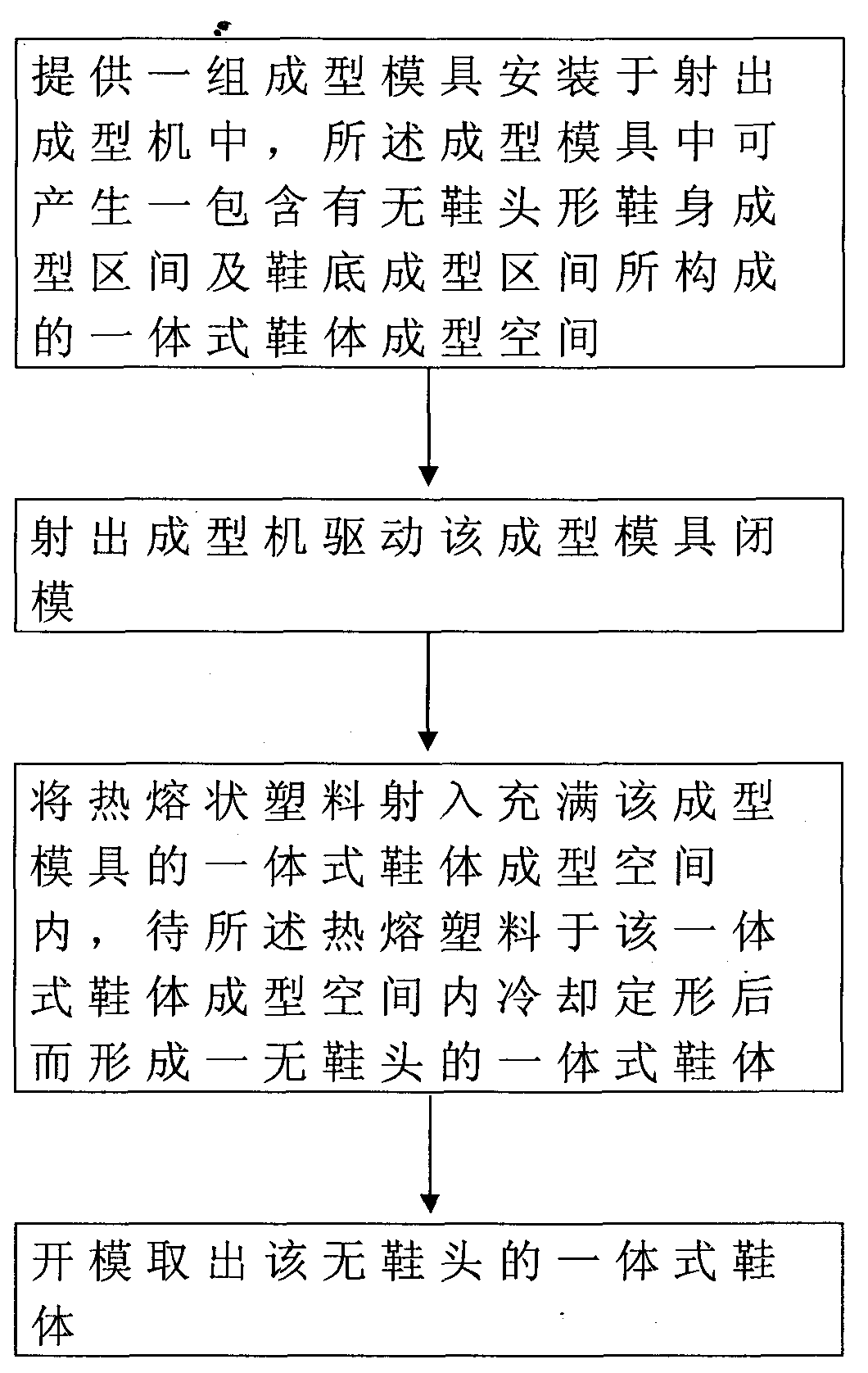

[0030] The specific implementation steps of the one-piece shoe body forming manufacturing method of the foot protection type sports shoes of the present invention, such as figure 1 The flowchart shown and Figure 2 ~ Figure 4 As shown, it mainly includes:

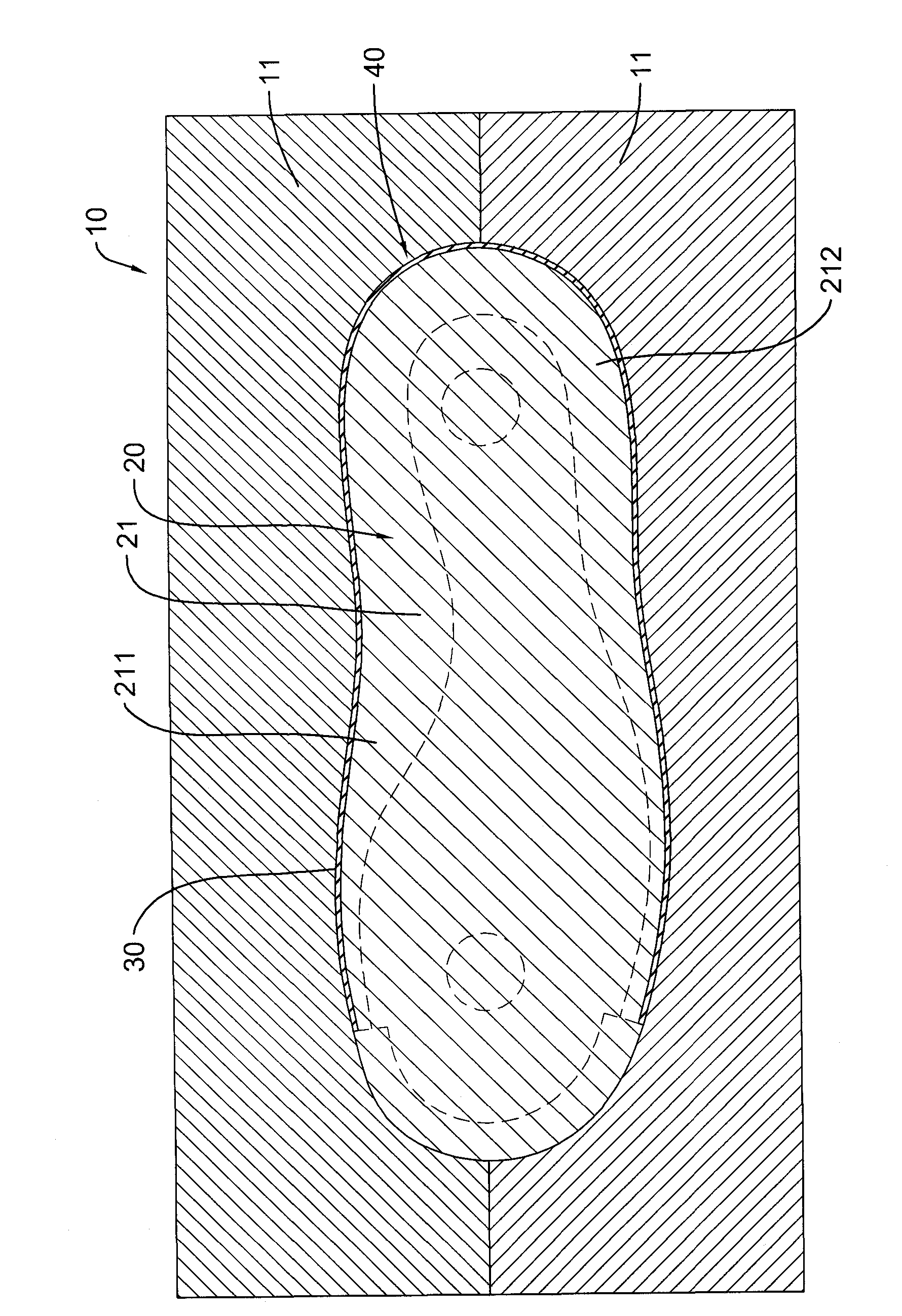

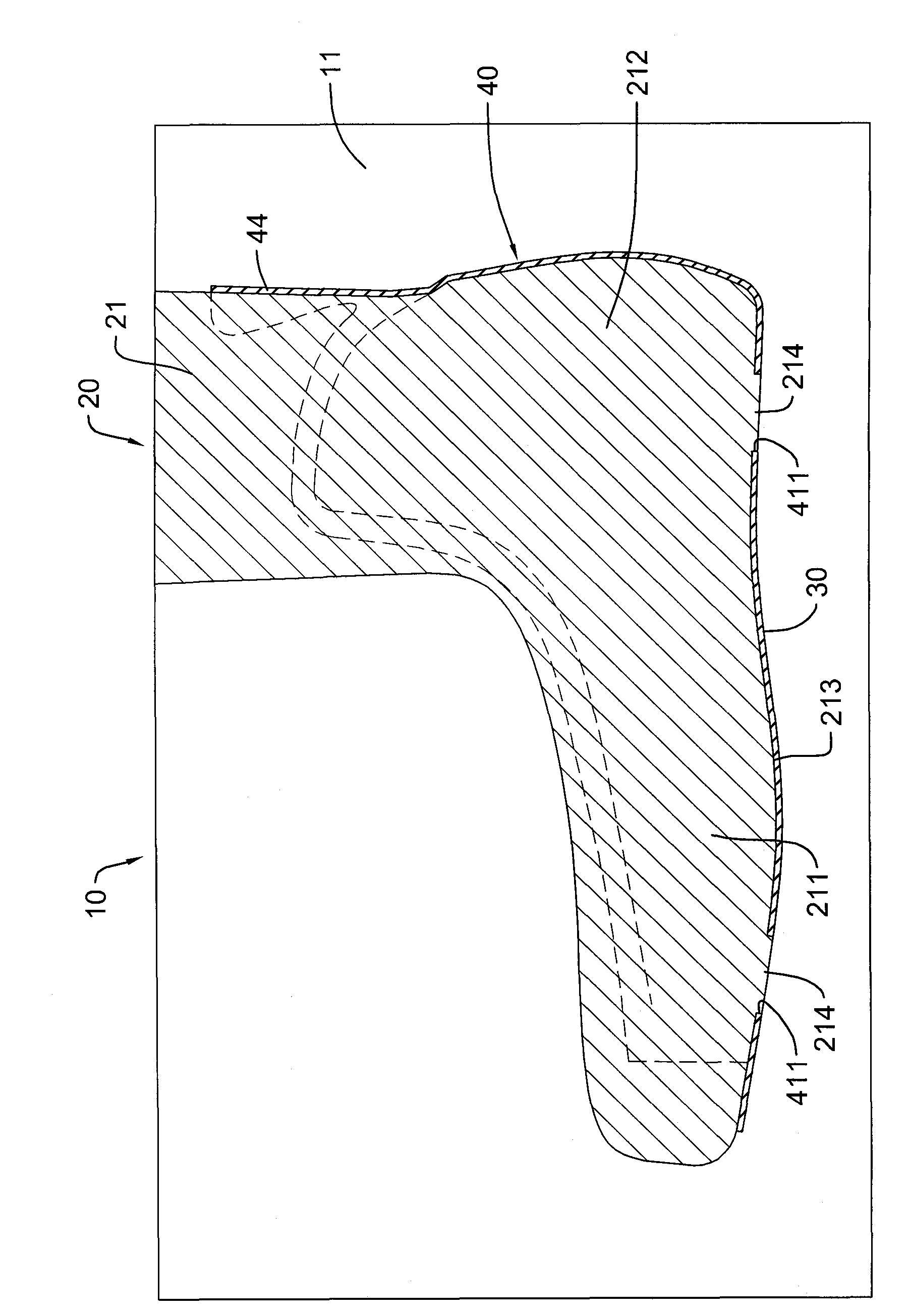

[0031] Provide a group of molding dies, which are installed in an injection molding machine, the injection molding machine has a combined outer mold 10 that can control the molding dies, and the inner mold 20 inside it is used for mold closing and opening. The action of the mold, the inner mold 20 can be placed in the mold cavity of a specific shape formed inside the combined outer mold 10 under control, and is used to produce a mold that includes a shoe sole molding section and is located on it. The one-piece shoe body forming space formed by the toe-less short-tube shoe body forming section;

[0032] The molding mold is driven by the injection molding machine to close the mold, so that the inner mold 20 is located in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com