Preparation method of high-crystallinity double-walled carbon nano tube

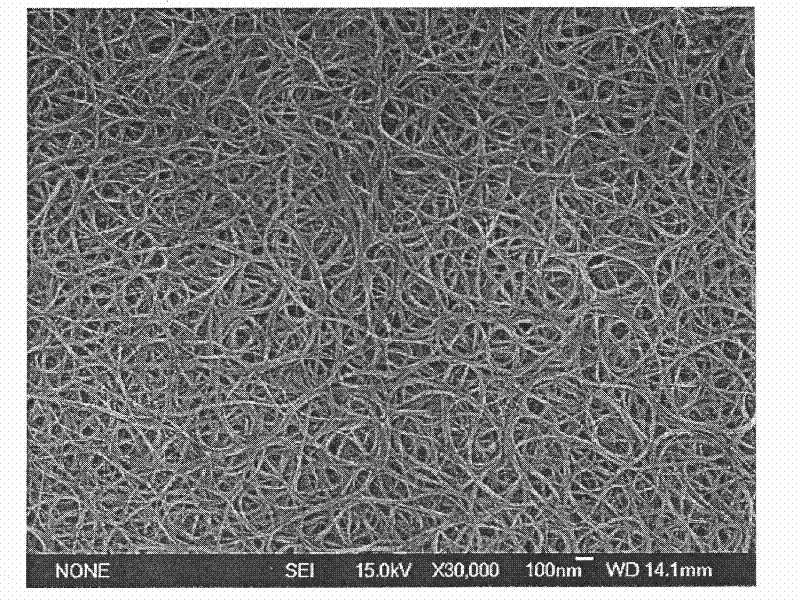

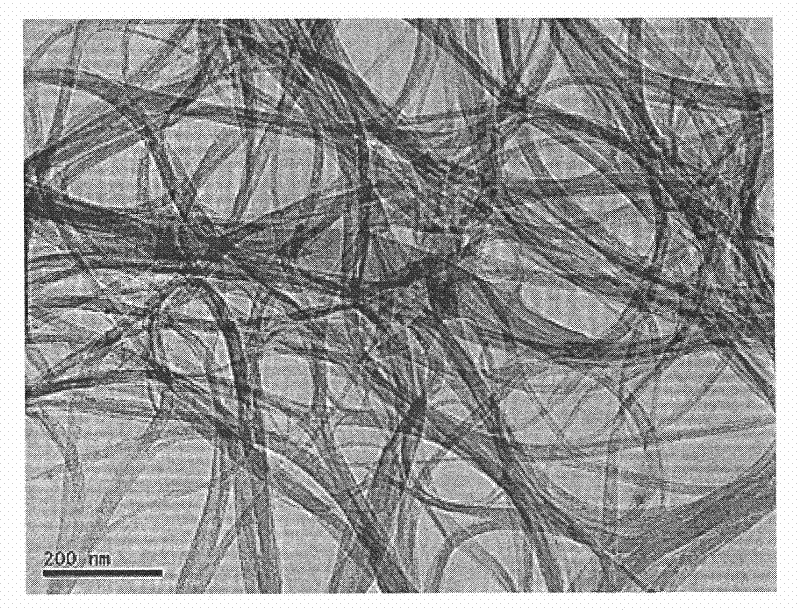

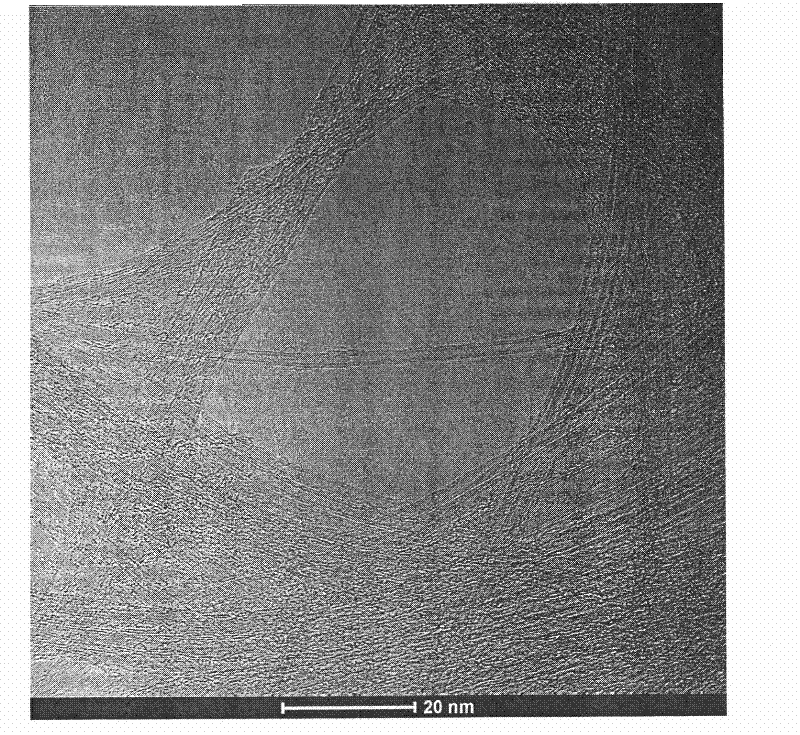

A technology of double-wall carbon nanotubes and high crystallinity, which is applied in the field of preparation of high-crystallinity double-wall carbon nanotubes, can solve the problems of wide distribution of double-wall carbon nanotube diameters, inability to mass-produce, and insufficient crystallinity. Achieve the effects of small average diameter, high crystallinity and narrow pipe diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention are described below.

[0019] In this embodiment, the preparation process and steps of double-walled carbon nanotubes are as follows:

[0020] (1) Preparation of anode carbon electrode rod containing catalyst

[0021] Use graphitizable carbon powder as raw material, add 1% iron catalyst by mass percentage, and 0.5% sulfur auxiliary catalyst, then press into cylindrical or square rods, sinter in an oxygen-deficient atmosphere at 800-1200°C, and then Then sinter in an oxygen-deficient atmosphere at 1400-2000°C.

[0022] (2) Preparation of carbon nanotubes

[0023] Prepared by DC arc discharge method. The cathode is a high-purity graphite rod, the anode is a catalyst-containing carbon electrode rod, and the discharge atmosphere is hydrogen or a mixed gas of hydrogen and argon with a volume fraction of hydrogen of 50%-80%. The discharge current is 50 amps to 200 amps. When discharging, the distance between the anode and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com