Waterway IC

A technology of integrated blocks and waterways, applied in non-polluted water treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems affecting the performance of pure water machines, complicated operation, and inconvenience. Achieve the effect of simple structure, easy manufacture, and reduce the possibility of water leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

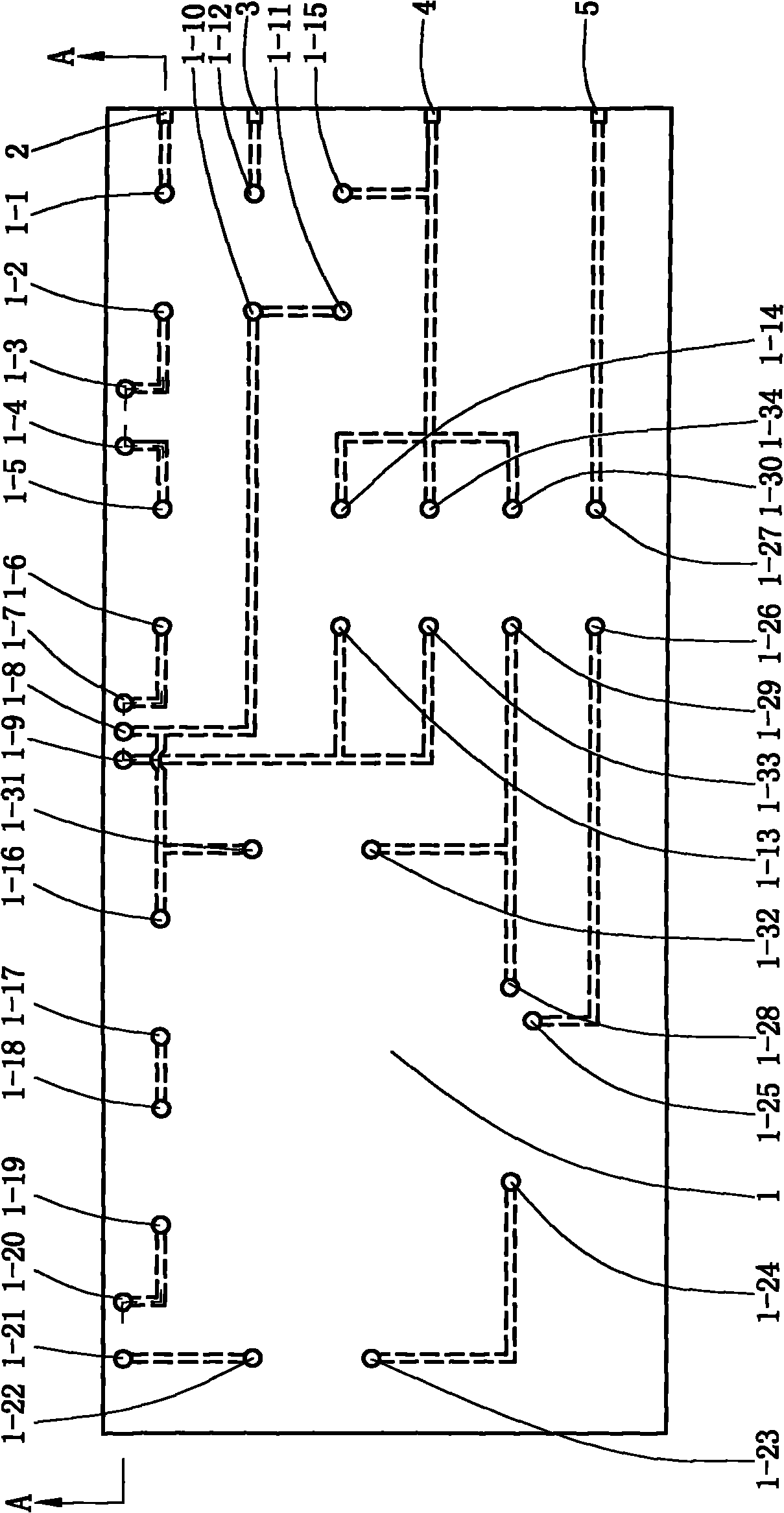

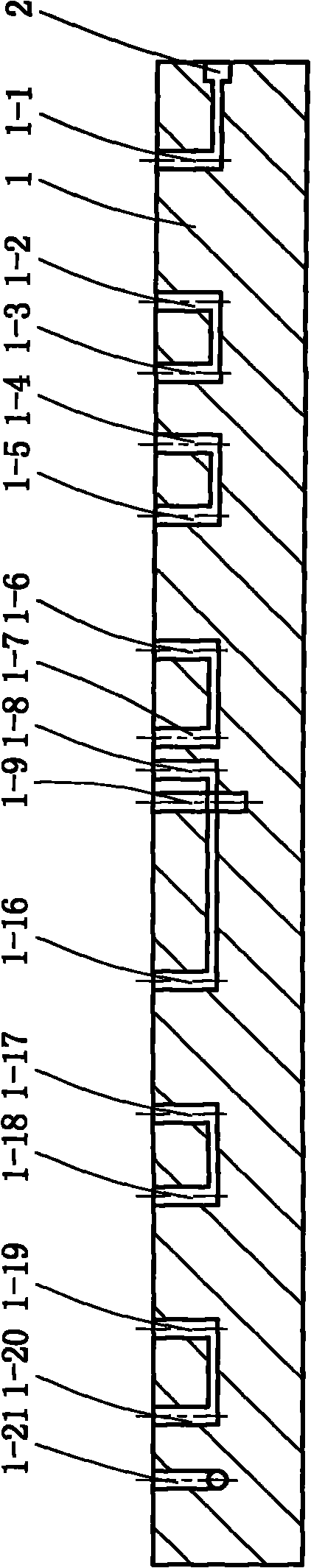

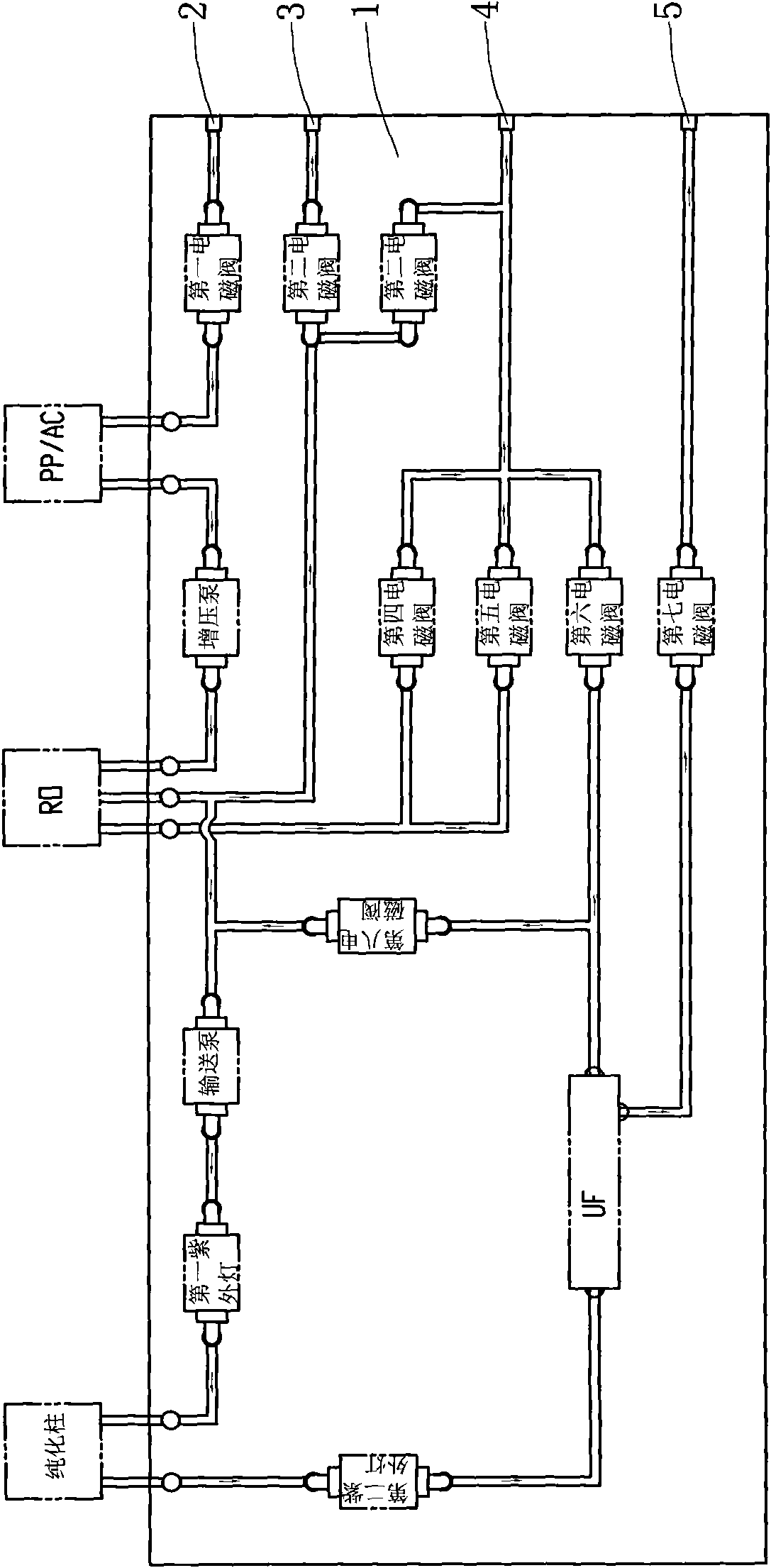

[0016] Such as Figure 1~3 As shown, a waterway integrated block includes a body 1 which is in the shape of a block or a plate. A water inlet 2, a pure water outlet 3, a concentrated water outlet 4 and an ultrapure water outlet 5 are set on the right end of the body 1 facing left. At the same time, fifteen blind holes are opened perpendicular to the upper surface of the body 1 at the right rear part of the body 1, wherein the first blind hole 1-1 communicates with the water inlet 2 through the water channel, and the second blind hole 1-2 communicates with the third blind hole. The blind hole 1-3, the fourth blind hole 1-4 and the fifth blind hole 1-5, the sixth blind hole 1-6 and the seventh blind hole 1-7 are respectively communicated via corresponding water channels. As an optimization, the above seven blind holes are arranged from left to right, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com