Gray vat dye with high fastness of resisting chlorine bleaching for tooling

A technology of chlorine bleaching and dye resistance, applied in the direction of organic dyes, etc., can solve the problems of low chlorine bleaching fastness, difficult to meet requirements, and easy to be damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

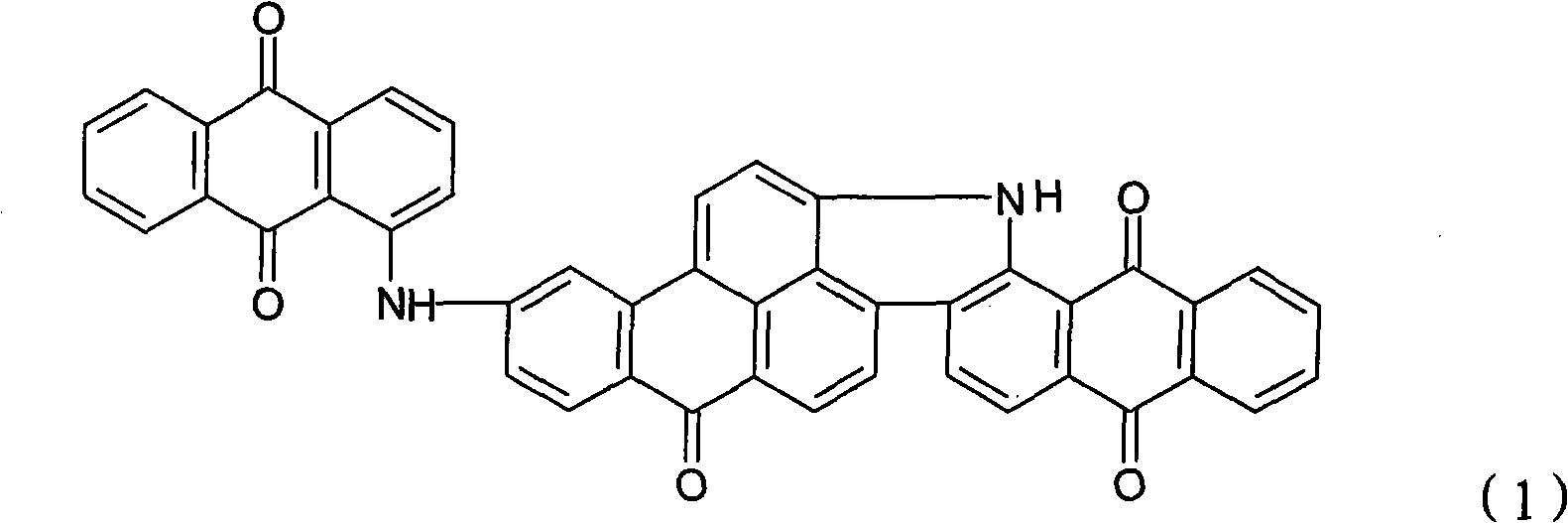

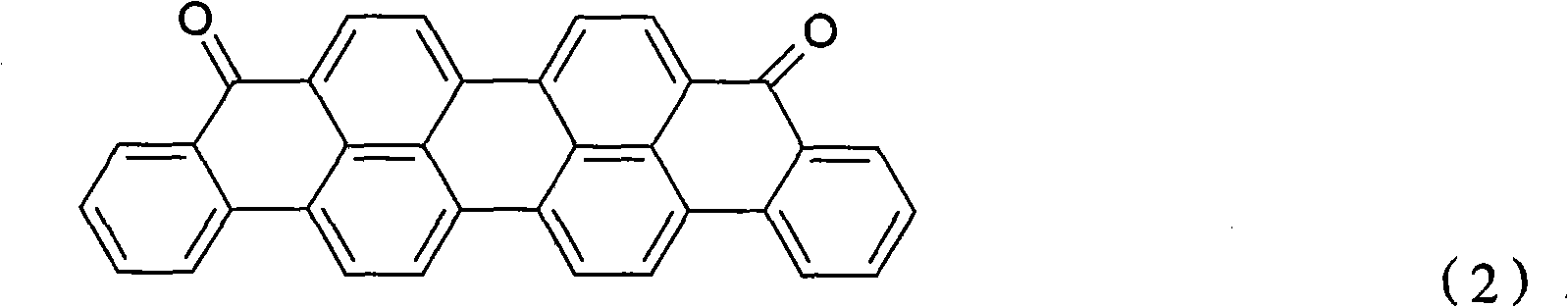

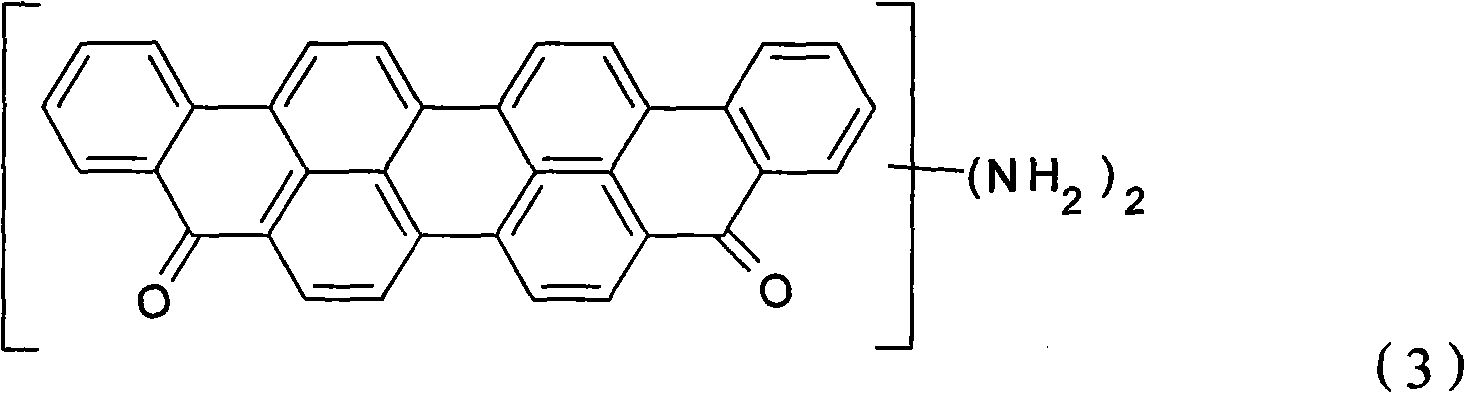

Method used

Image

Examples

Embodiment 1-4

[0020] According to the data shown in Table 1, after beating the vat dye monomer A, vat dye monomer B and vat dye monomer C filter cakes and dispersant in the metering ratio, use wet pulverization technology to pulverize and grind, and pass through the pipeline after grinding for 70 hours Delivered to the spray drying tower for drying, sprayed with the amount of anti-dust oil shown in Table 1 at the same time, and finally packaged the finished product, and the waste gas generated during the spray drying was filtered and dusted several times by the cyclone dust removal device.

[0021] Table 1

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com