Slag returning method for reducing gold content of smelting slag

A technology of smelting slag and gold content, which is applied in the field of smelting slag return, can solve the problems of not very ideal, high gold content in smelting slag, unsatisfactory gold and silver recovery rate, etc., achieve stable indicators, low gold content in smelting slag, and return slag method simple and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

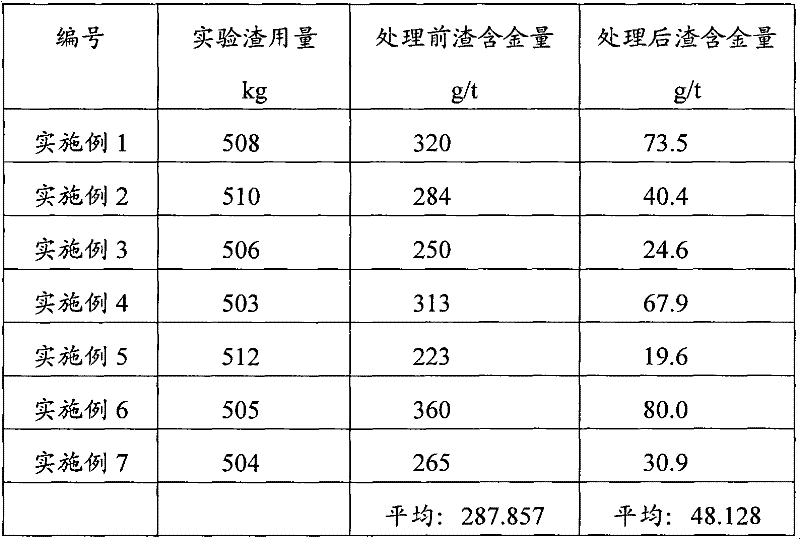

Examples

Embodiment 1

[0015] A method of returning slag to reduce the gold content of smelting slag. The processing capacity of smelting slag is 508kg: before the smelting slag is returned to the pot, use a slag scoop to skim off the graphite slag floating on the smelting slag. Coat a layer of acetylene ash with a thickness of 0.18mm, and then scoop the returned smelting slag into the inverted cone pier mold, and vibrate the pier mold (with a hammer head weighing 1000g in two minutes to manually beat it evenly) pier mold outer wall 13 times), after cooling, the smelting slag is knocked out, and the returned alloy at the smelting slag slag tip part is knocked off and recovered.

Embodiment 2

[0017] A method of returning slag to reduce the gold content of smelting slag. The processing capacity of smelting slag is 510kg: before the smelting slag is returned to the pot, use a slag scoop to skim off the graphite slag floating on the smelting slag. Coat a layer of acetylene ash with a thickness of 0.13mm, then scoop the returned smelting slag into the inverted cone pier mold, and vibrate the pier mold (with a hammer head weighing 750g in two minutes to manually beat the pier mold outer wall 12 times), after cooling, the smelting slag is knocked out, and the returned alloy at the tip of the smelting slag is knocked off and recovered.

Embodiment 3

[0019] A method of returning slag to reduce the gold content of smelting slag. The processing capacity of smelting slag is 506kg: before the smelting slag is returned to the pot, use a slag scoop to skim off the graphite slag floating on the smelting slag. Coat a layer of acetylene ash with a thickness of 0.15mm, and then scoop the returned smelting slag into the inverted cone pier mold, and vibrate the pier mold (with a hammer head weighing 500g in two minutes to manually beat it evenly) pier mold outer wall 10 times), after cooling, the smelting slag is knocked out, and the returned alloy at the tip of the smelting slag is knocked off and recovered.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com