A kind of beneficiation process of gold-antimony paragenetic ore

A kind of ore and process technology, which is applied in the field of beneficiation process of gold-antimony symbiotic ore, can solve the problems of affecting the quality of antimony concentrate, difficult to dissociate, and complicated intercalation relationship, and achieve the effect of improving the comprehensive recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

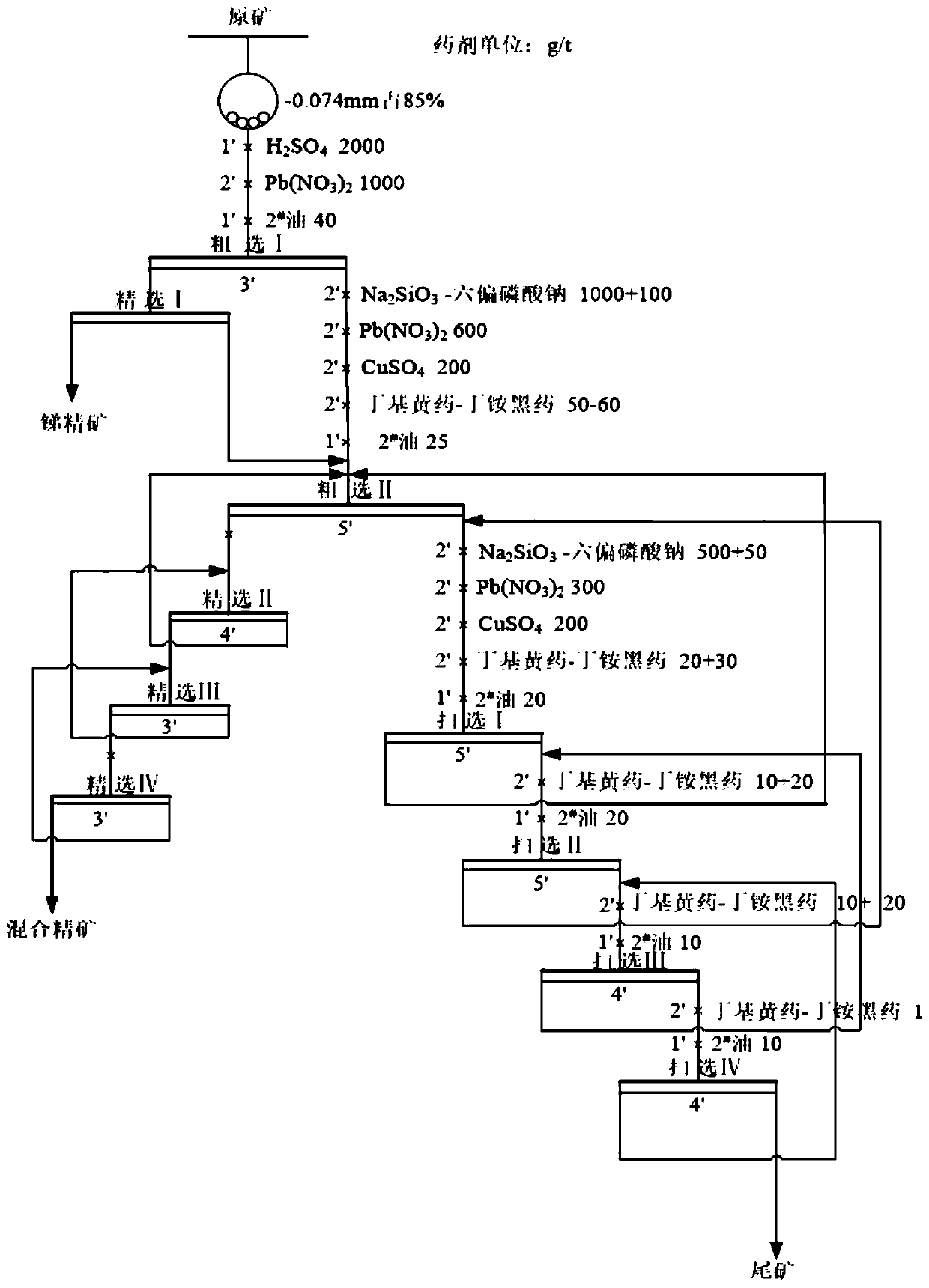

[0017] The beneficiation process of a gold-antimony symbiotic ore of the present invention will be described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, other embodiments obtained by persons of ordinary skill in the art without making creative efforts all belong to the protection scope of the present invention.

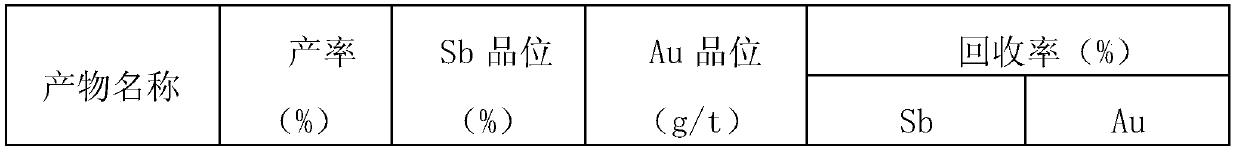

[0018] The ores used in this embodiment are metal minerals mainly sulfides, which are primary sulfide ores containing gold and antimony of stibnite and arsenopyrite. The ore sample was crushed and sieved to prepare a product with a particle size of -2mm, which was used as a test sample after mixing. The analysis results of the sample showed that the grade of Sb was 6.89%, and the grade of Au was 2.46g / t.

[0019] Carry out a systematic process condition optimization test for the ore, and condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com