Supported nano-gold catalyst by taking cerium oxide as carrier and preparation method thereof

A catalyst and cerium oxide technology, applied in the field of supported nano-gold catalyst and its preparation, can solve the problems of increasing the chance of gold particle aggregation, low actual loading rate, and decreased activity, and achieve fast reaction speed, low cost, and high capacity strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Raise cerium nitrate to 800°C at a heating rate of 5°C / min, and roast at 800°C for 5 hours to obtain light yellow CeO 2 Powder, take 0.5g of cobalt nitrate, dissolve it with 1.5ml of distilled water, then take 0.2g of citric acid and dissolve it in the cobalt nitrate solution, then pour the solution into 1g of cerium oxide powder to form a slurry, stir it evenly and then soak it for 12 hours , dried at 120°C for 12h, and calcined at 300°C for 3h to obtain a mixed oxide support.

[0020] Weigh 1g of mixed oxide carrier and add it to 50ml of distilled water, stir evenly, add dropwise 0.1ml of 20g / L chloroauric acid solution, place in a water bath and heat to 80°C, then adjust the pH value to 9 with NaOH, strongly React under stirring for 120min, pour off the solution, wash with deionized water until no detectable Cl -1 Chloride. After drying at 60°C for 16 hours, the finished catalyst 1 was obtained. The gold content of the obtained catalyst was 0.1% (mass p...

Embodiment 2~4

[0023] The preparation method is as in Example 1, except that the addition of chloroauric acid is adjusted to 0.3ml, 0.5ml, and 0.9ml respectively. The gold contents of the prepared catalysts were respectively 0.3%, 0.5%, and 0.9% (mass percentage).

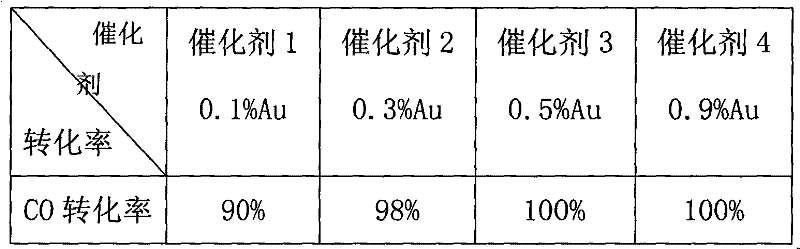

[0024] The catalysts of Examples 1-4, the activity evaluation results after 0.5min of reaction are listed in Table 1.

[0025] The reaction result of table 1 embodiment 1~4

[0026]

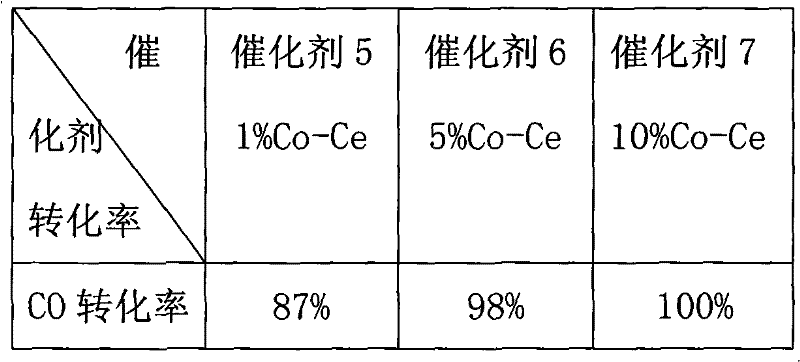

Embodiment 5

[0028] Heat cerium nitrate to 800°C at a heating rate of 5°C / min, and roast at 800°C for 5 hours to obtain light yellow CeO 2 Powder, take 0.05g cobalt nitrate, dissolve it with 1.5ml distilled water, then take 0.2g citric acid and dissolve it in the cobalt nitrate solution, then pour the solution into 1g cerium oxide powder to form a slurry, stir it evenly, and then soak it for 12h. Dry at 120°C for 12 hours, and calcined at 300°C for 3 hours to obtain a mixed oxide carrier.

[0029] Weigh 1g of the mixed oxide carrier and add it to 50ml of distilled water, and at the same time add 0.1ml of 20g / L chloroauric acid solution dropwise, place in a water bath and heat to 80°C, then adjust the pH value to 9 with NaOH, and react for 120min under strong stirring. The solution was decanted and washed with deionized water until no detectable Cl -1 Chloride. After drying at 60°C for 16 hours, the finished catalyst 5 was obtained. The gold content of the obtained catalyst was 0.1% (mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com