Production method of metal fibre

A metal fiber and metal technology, which is used in the production of high-quality metal fibers and the purification of low-melting active metals, can solve the problems of low fiber quality, low work efficiency, and inability to produce high-quality fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

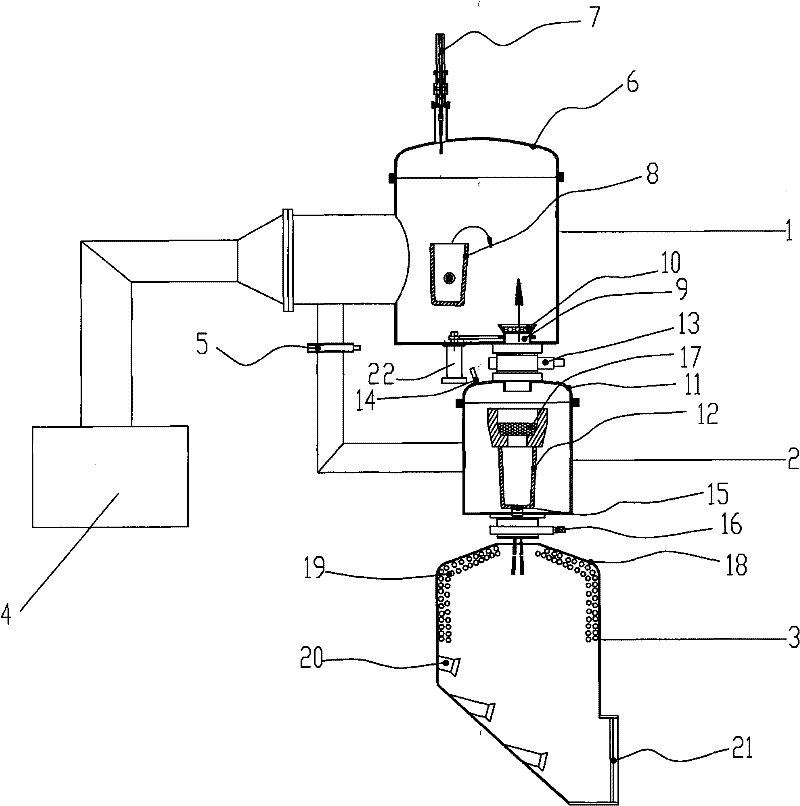

[0022] see figure 1 , The metal fiber production device of the present invention includes a metal melting system 1 , a heat preservation and pressure system 2 , a fiber cooling system 3 and a vacuum system 4 . The metal melting system 1 is used for melting metal. The heat preservation and pressure system 2 is connected to the metal melting system 1 for heat preservation and pressure of the molten metal. The fiber cooling system 3 is connected to the heat preservation and pressure system 2 to receive and cool the molten metal ejected from the heat preservation and pressure system. The vacuum system is connected to the metal melting system and the heat preservation and pressure system to provide Vacuum environment. The metal melting system 1 and the heat preservation and pressurization system 2 share a set of vacuum system 4, and the vacuum system 5 and the heat preservation and pressurization system 2 are controlled to be isolated or connected together through a valve 5.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com