Blade for wind turbine

A technology of wind turbines and blades, which is applied to wind turbine components, wind engines, and wind turbines in the same direction as the wind, and can solve the problems of wind turbine power generation reduction, overall weight increase, and aerodynamic efficiency decline. Guaranteed power generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

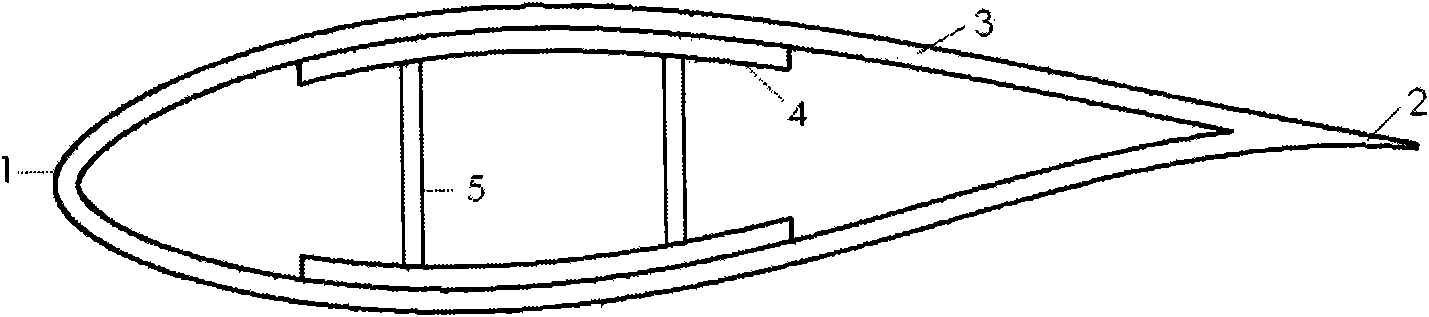

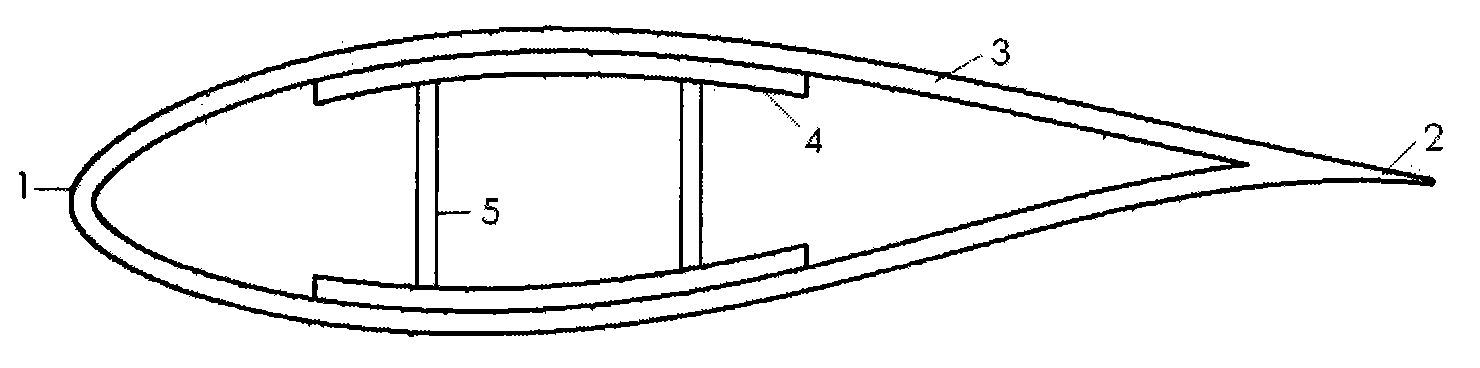

[0016] see figure 1 Shown is a blade for a wind generator, the blade is made of glass fiber uniaxial fabric. Among them, the outer skin 1 of the blade is made of triaxial glass fabric, which bears most of the shear load, and improves the torsional stiffness of the blade to ensure the shape of the blade; the trailing edge of the blade 2 is bonded by adhesive; the core material 3 is made of PVC and balsa wood, Reduce the weight of the blade and improve the anti-stabilization performance of the blade; the main spar cap 4 adopts high-performance glass fiber unidirectional fabric, which is the main bearing part of the blade, and the stiffness of the blade is improved through the improvement of the invention, and the bearing capacity is stronger under the same weight; The cut rib 5 is mainly made of PVC foam, which supports the main beam.

[0017] The above-mentioned high-performance unidirectional composite materials are applied in the design and development of megawatt blades to ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap