Inverted input blocking mechanism

A technology of reverse input and input side, applied to mechanical equipment, one-way clutches, automatic clutches, etc., can solve the problems of complex structure and high cost of reverse input blocking mechanism, and achieve the effect of simplified structure and low-cost manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Hereinafter, the configuration of the present invention will be described in detail with reference to the drawings.

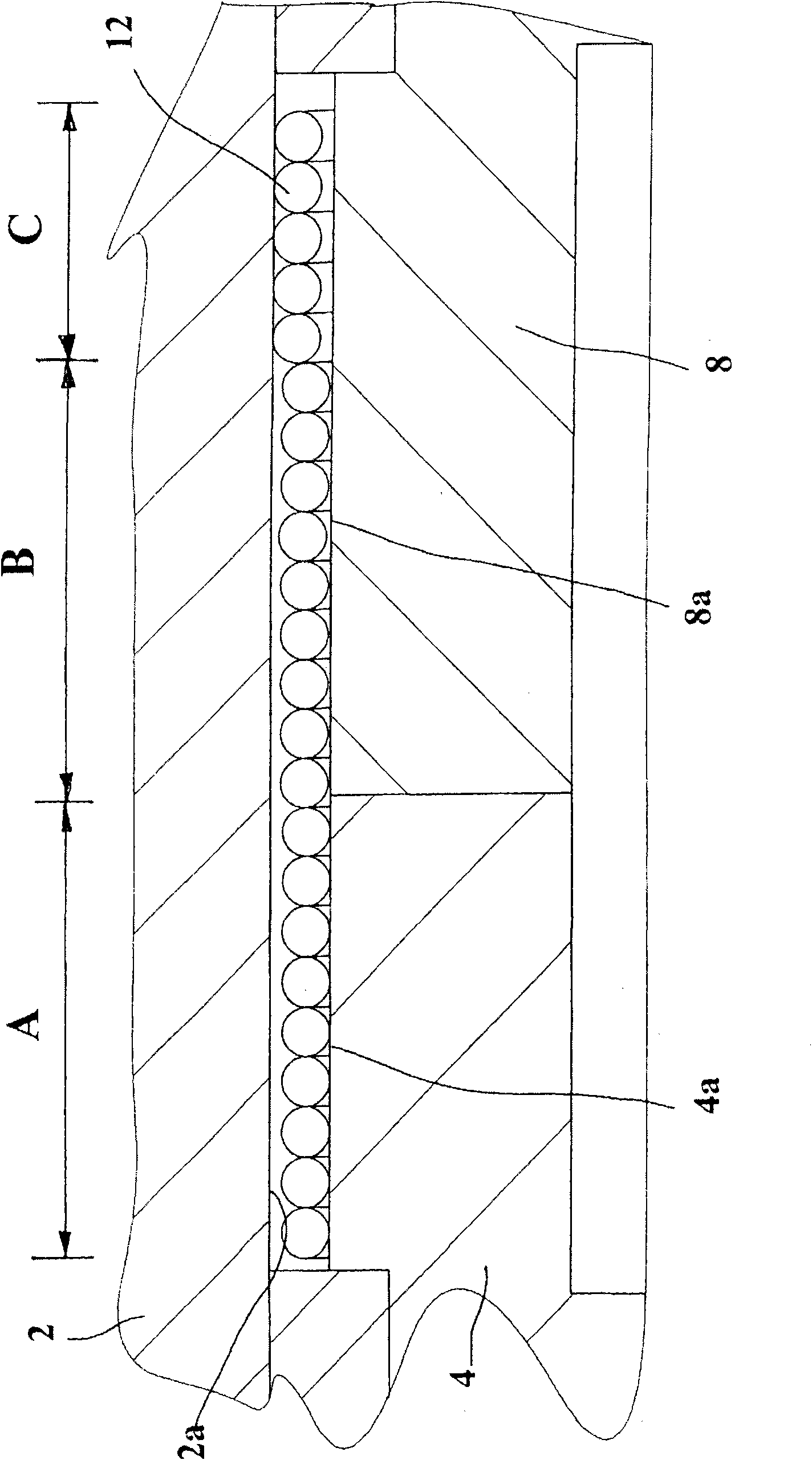

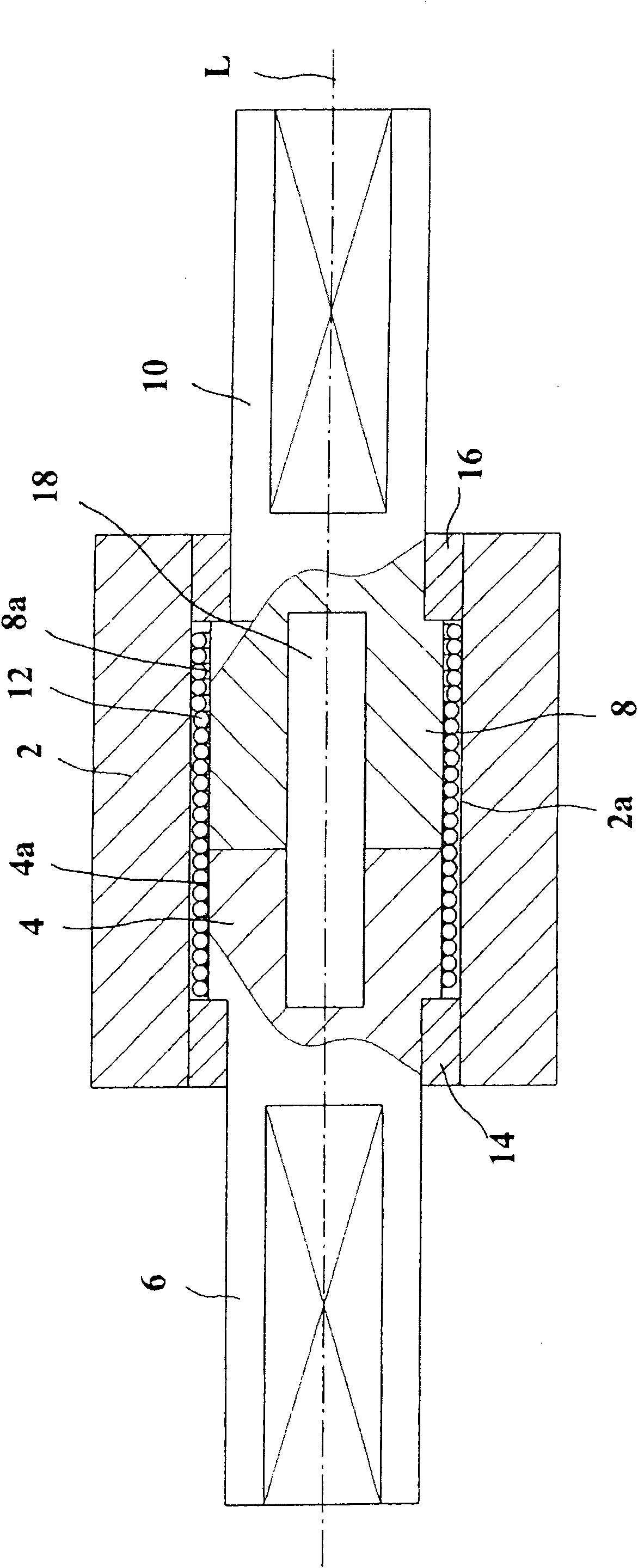

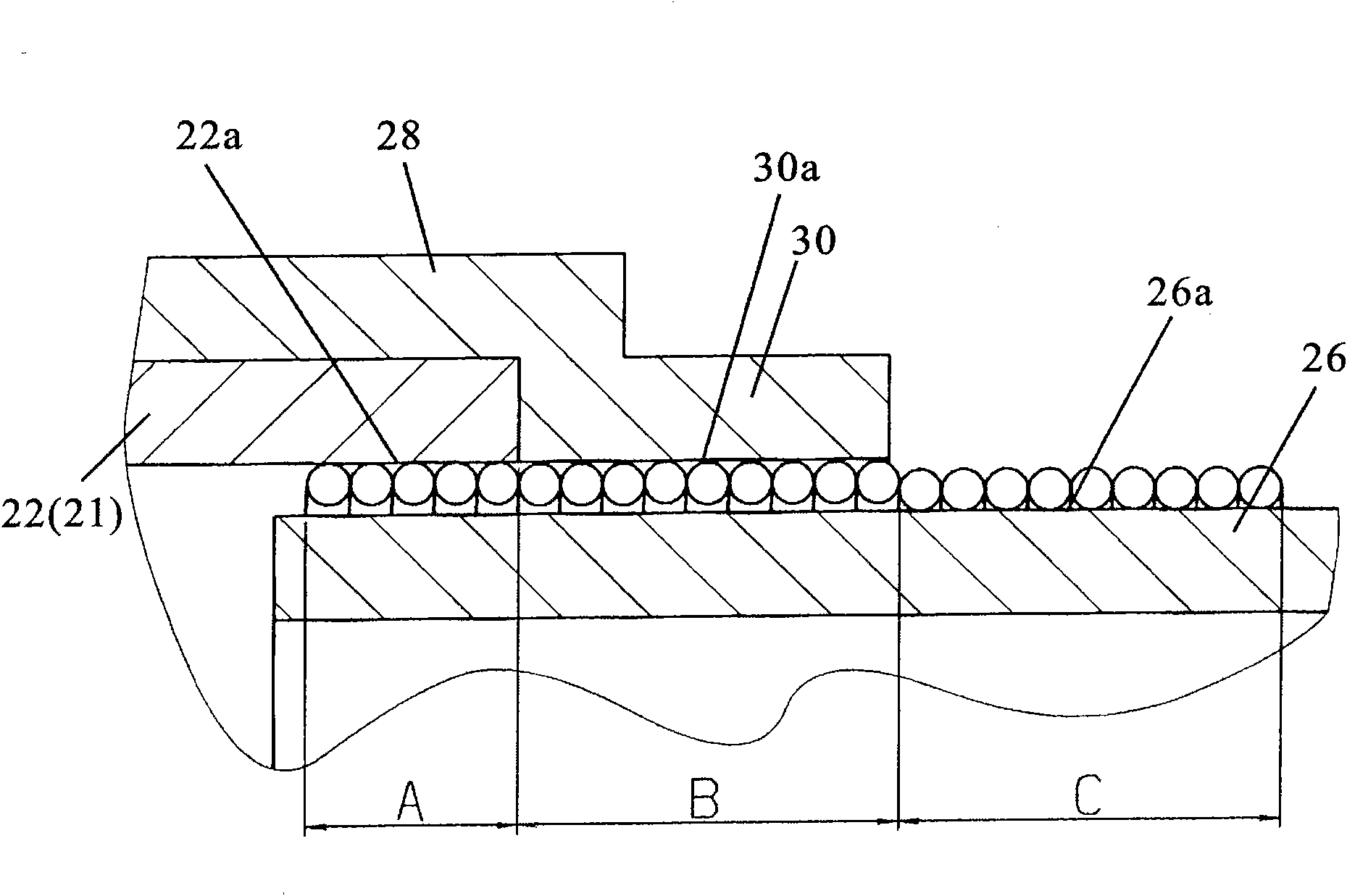

[0063] figure 2 A cross-sectional view showing an embodiment of the reverse input blocking mechanism of the present invention, the main components are: a fixed-side member 2 made of a cylindrical member, an input shaft 6 integrally formed with an input-side rotating member 4, and an output-side rotating member 4. The output shaft 10 and the coil spring 12 are integrally formed in the part 8 .

[0064] The input shaft 6 is disposed so as to protrude outward from the inside of the fixed-side member 2 , and the input-side rotary member 4 having a cylindrical shape larger than the shaft diameter is integrally formed on the input shaft 6 . The output shaft 10 is similarly disposed so as to protrude from the inside of the fixed side member 2 to the outside in the opposite direction, and the cylindrical output side rotating member 8 having a larger diameter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com