Polyvinyl chloride joint

A technology of polyvinyl chloride and pipe fittings, applied in the field of pipe joints, can solve the problems of inconvenient installation at high altitude for workers, affect the effective light-to-heat conversion of solar energy, and consume a lot of labor, etc., and achieve the effect of small size, light weight, and prevention of external leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

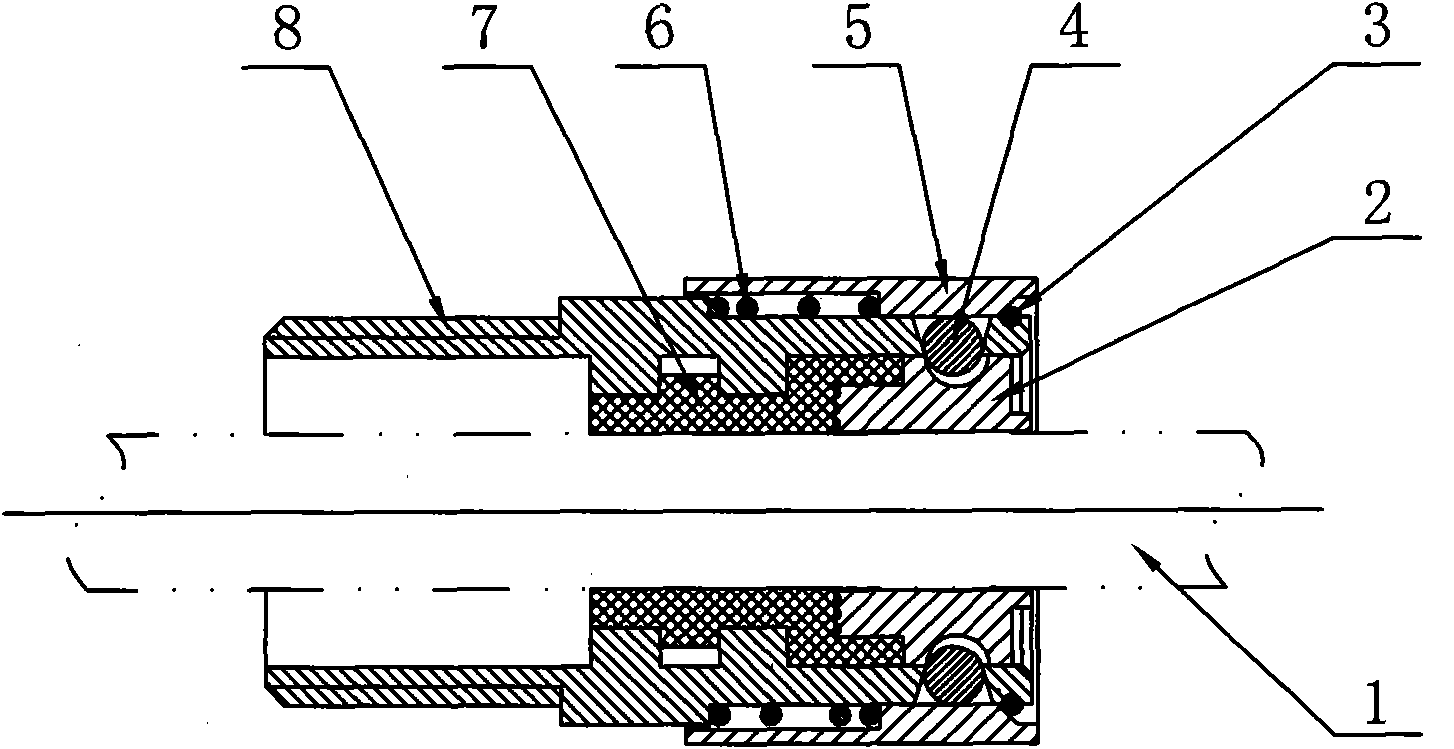

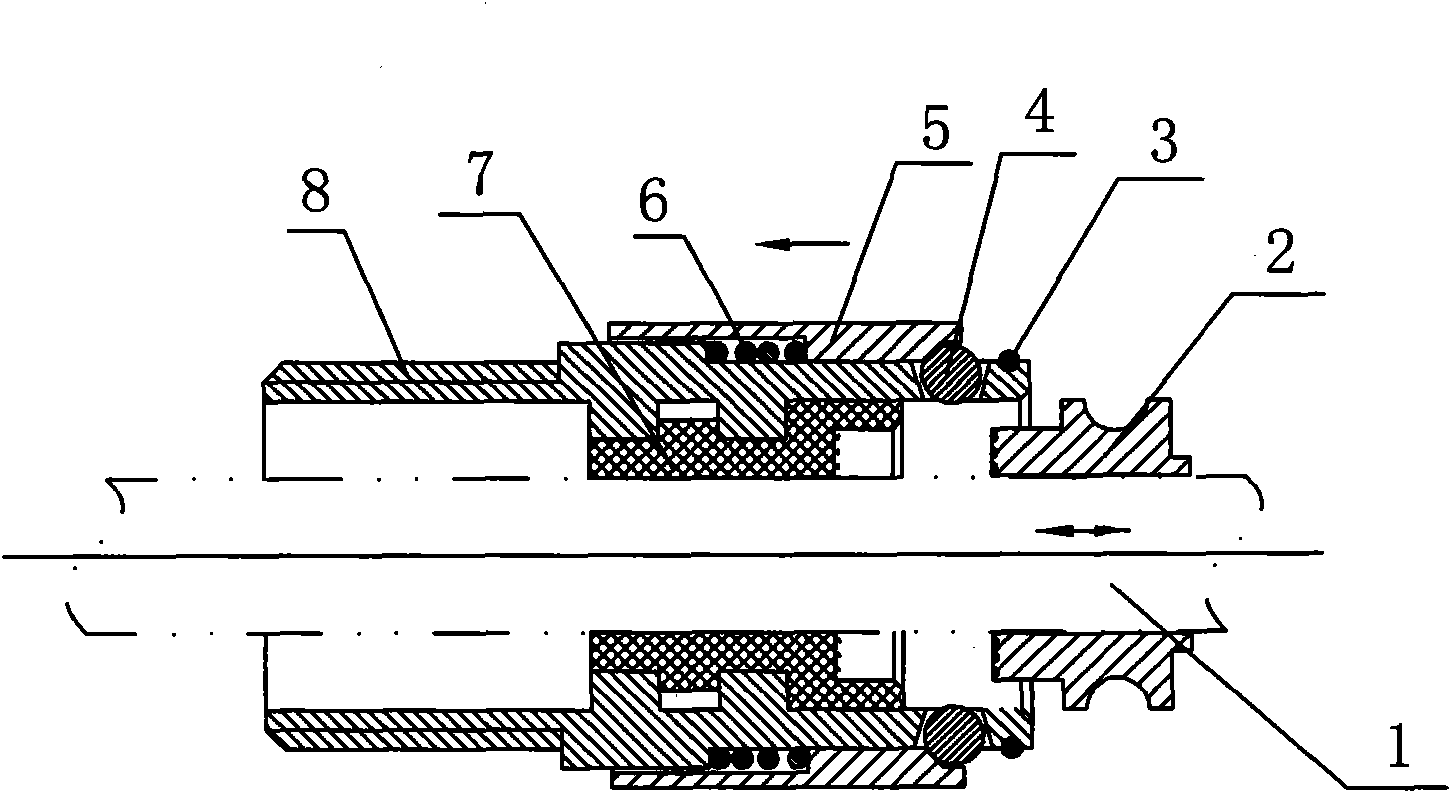

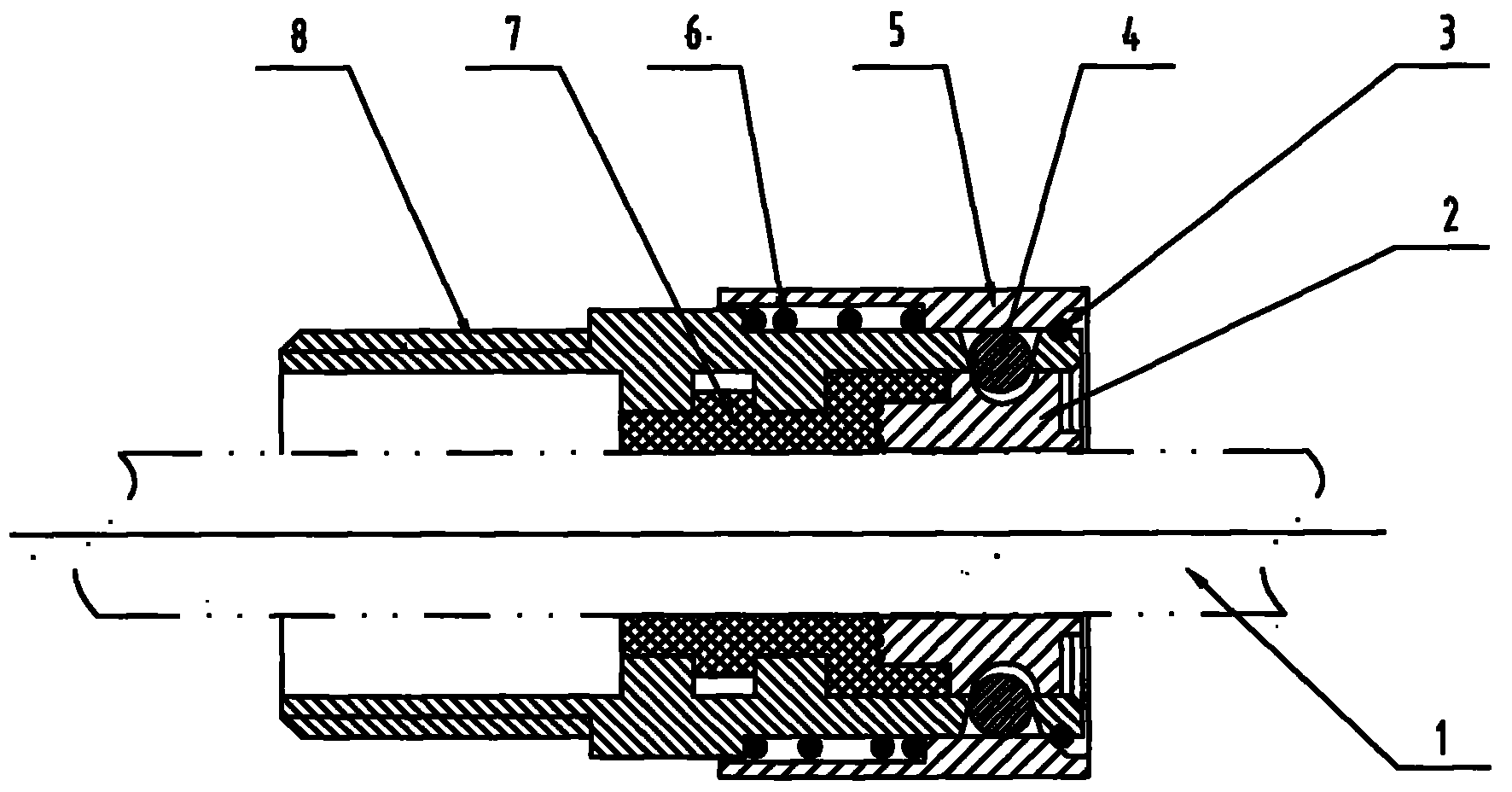

[0019] The structure of this embodiment is as figure 1 As shown, a polyvinyl chloride joint pipe fitting for a water tank and a heat pipe of a solar water heater, it includes a plug 2 welded into one body with the heat pipe 1, and a semicircular groove matching the steel ball 4 is arranged in the middle. The water tank is welded or threaded joint 8, a groove is arranged on the right side of the joint 8, and a snap ring 3 is arranged in the middle to prevent the ferrule 5 from being ejected by the compression spring 6. The joint part 8 has several steel ball installation holes on the left side of the groove. The diameter of these installation holes on the inner wall is slightly smaller than the diameter of the steel ball 4, and the installation diameter of the outer wall is slightly larger than the diameter of the steel ball 4. There is a compression spring 4 between cover 5.

[0020] The plug piece 2 is a metal circular tubular body, its inner diameter matches the heat pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com