Method for thermal treatment of organic matter of low calorific value

A technology with low calorific value and organic substances, which is applied in the field of heat treatment and can solve the problems of using and low calorific value organic substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

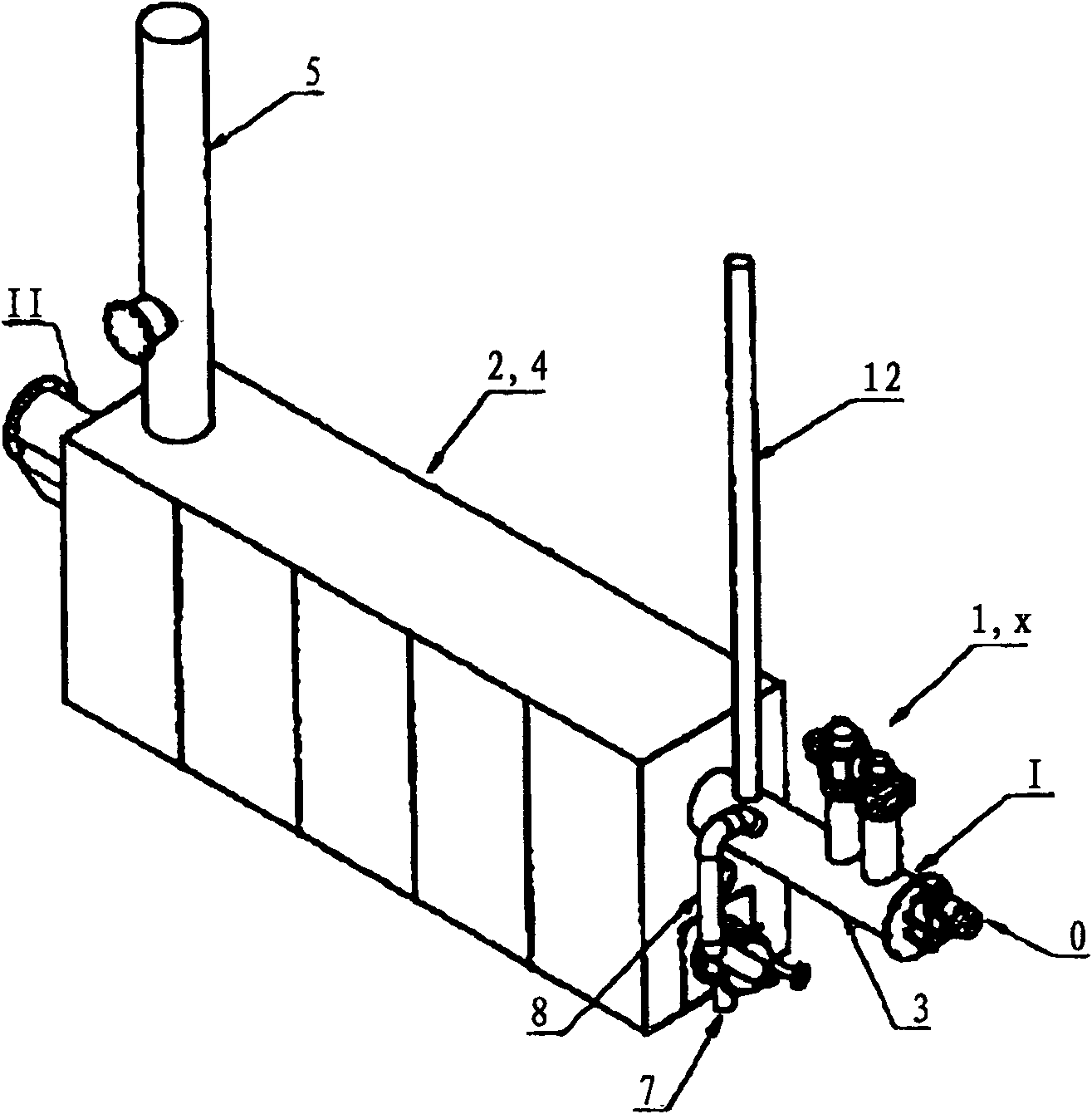

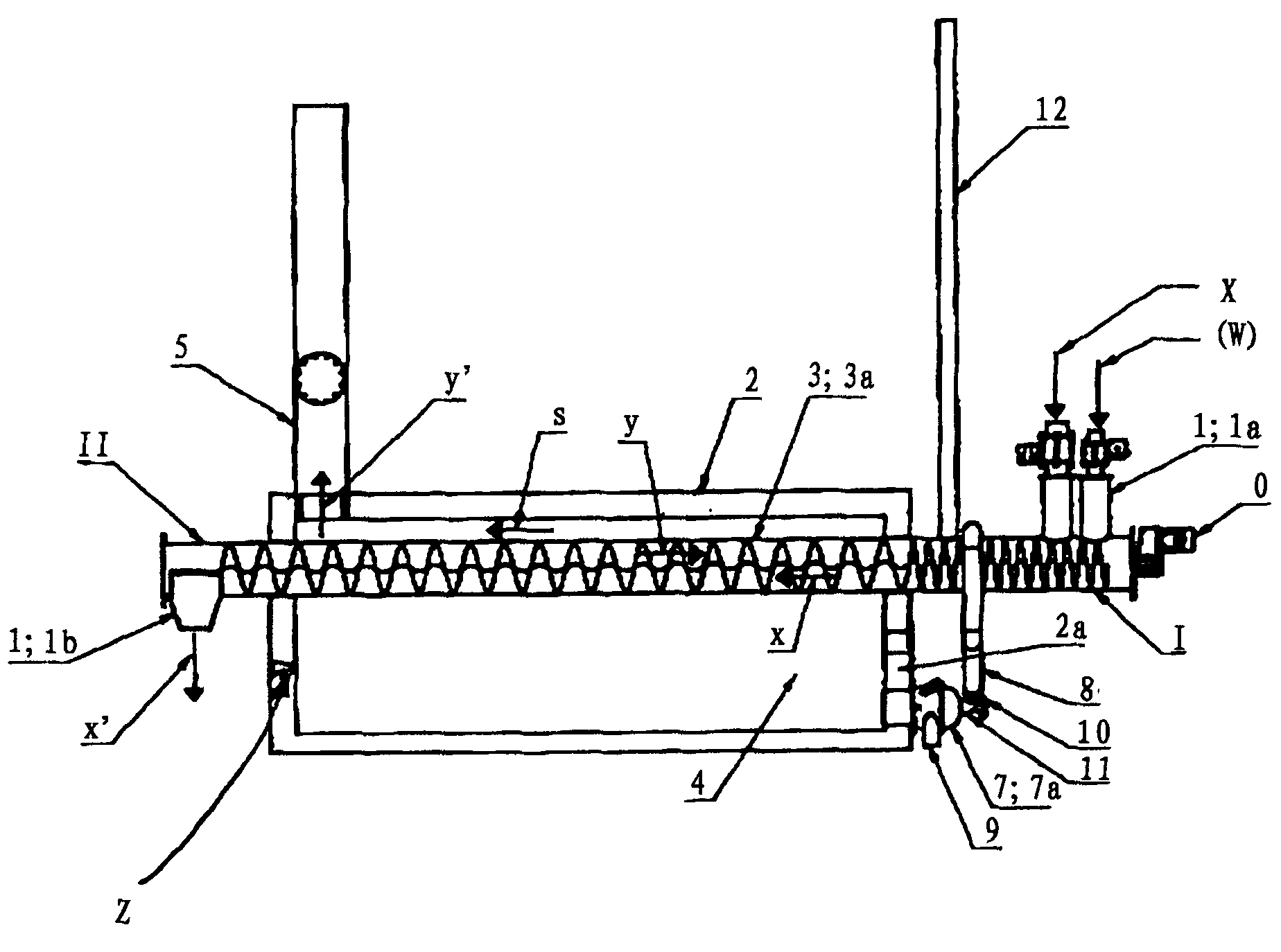

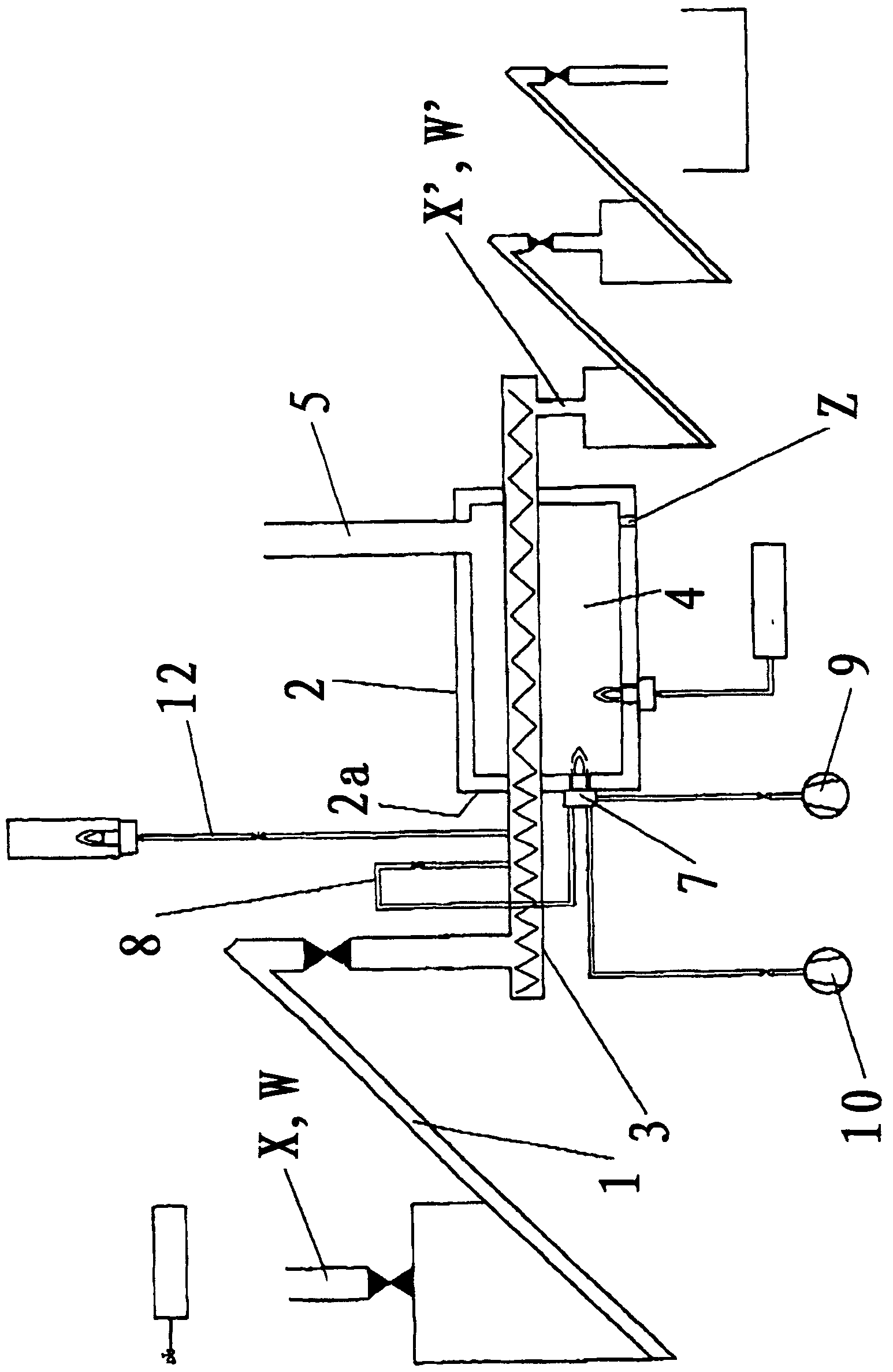

[0014] The invention relates to a method for separating char by thermal treatment, in which method the substance x to be treated is conveyed by means of a feed device 1 to a conveyor device 3 connected to a substantially Thomson reformer type Processing space 2. The substance x to be treated is moved in the treatment space 2 in its longitudinal direction by means of a conveyor device 3 closed relative to the treatment space 2, wherein the substance x to be treated will pass from the treatment space to the substance x contained in the conveyor system The pyrolysis gas y formed by the heat transfer is sent to the combustion space 4 provided in the processing space to burn the gas. The flue gas y' thus formed is discharged from the treatment space by means of discharge means 5, and the heat-treated substance x' is discharged from the conveyor means for further processing. In order to increase the calorific value of the substance to be treated, a substance x with a low calorific ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap