Large-power modular power supply and cooling structure thereof

A technology of modular power supply and heat dissipation structure, applied in the field of power supply, can solve the problems of high requirements on pipeline layout, shaping, welding and assembly construction process, large module power supply volume, complicated maintenance work, etc. Good leakage performance to ensure uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

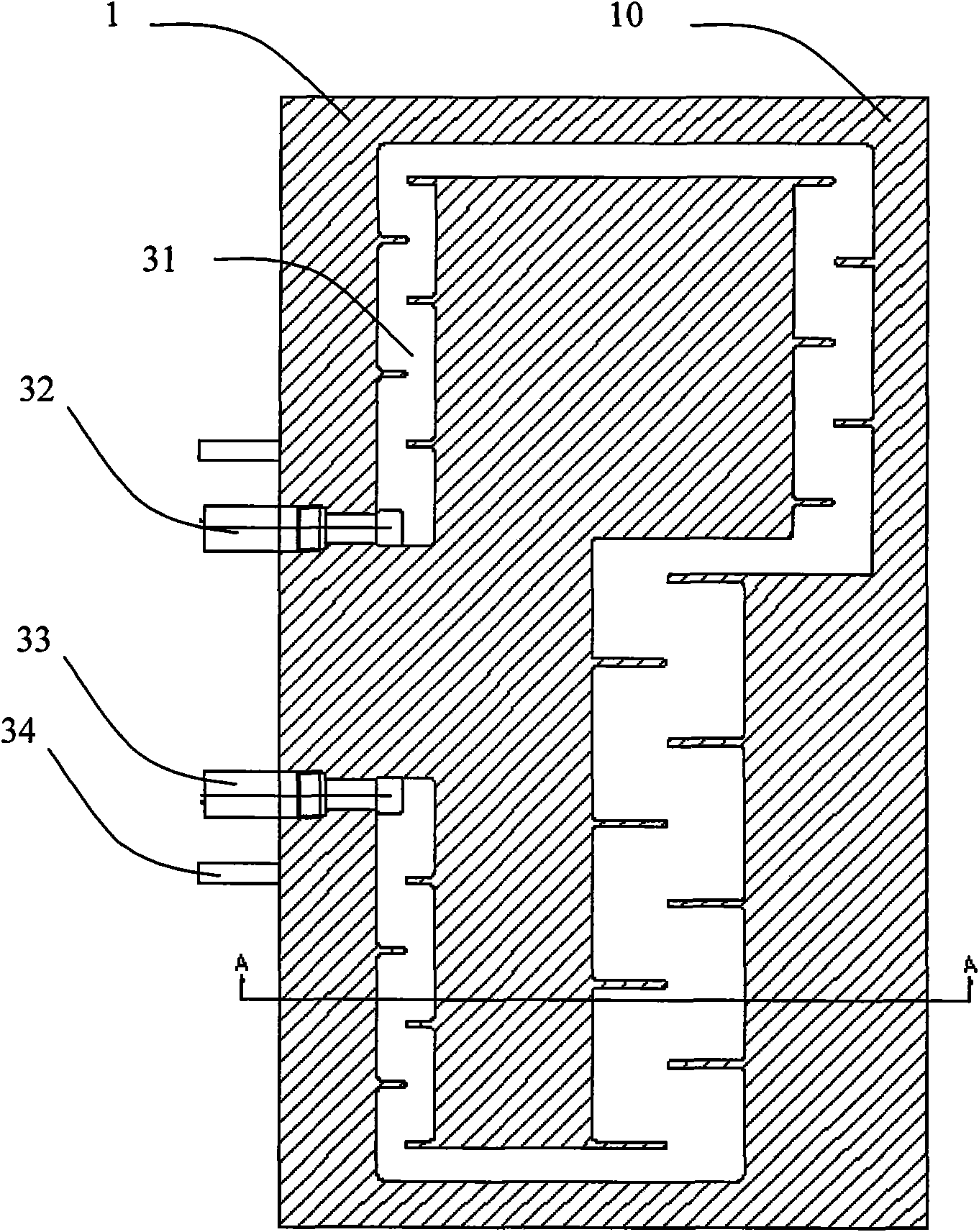

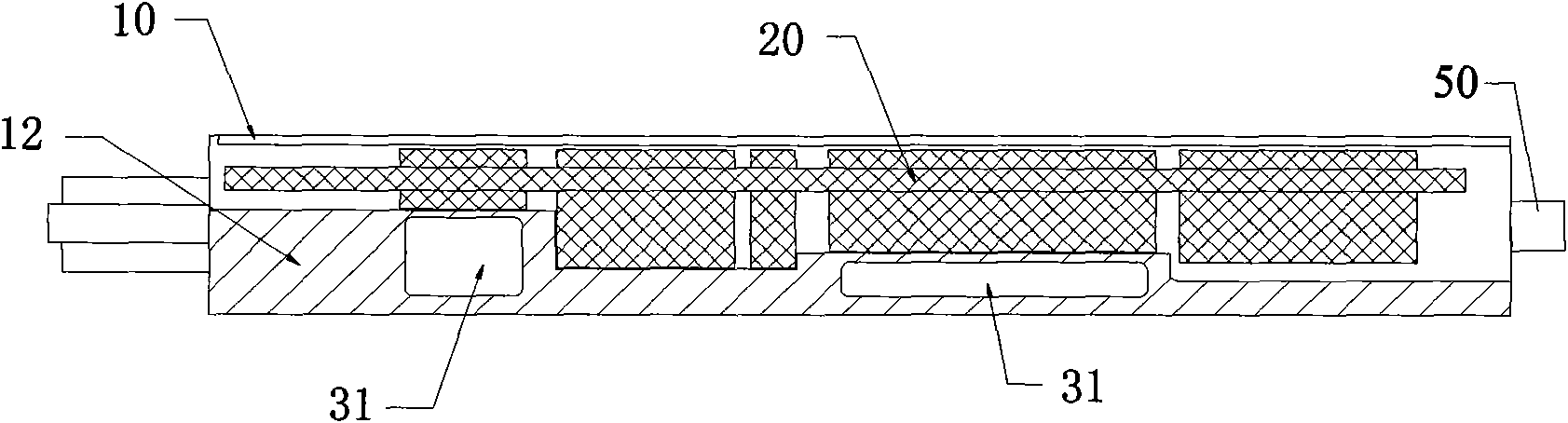

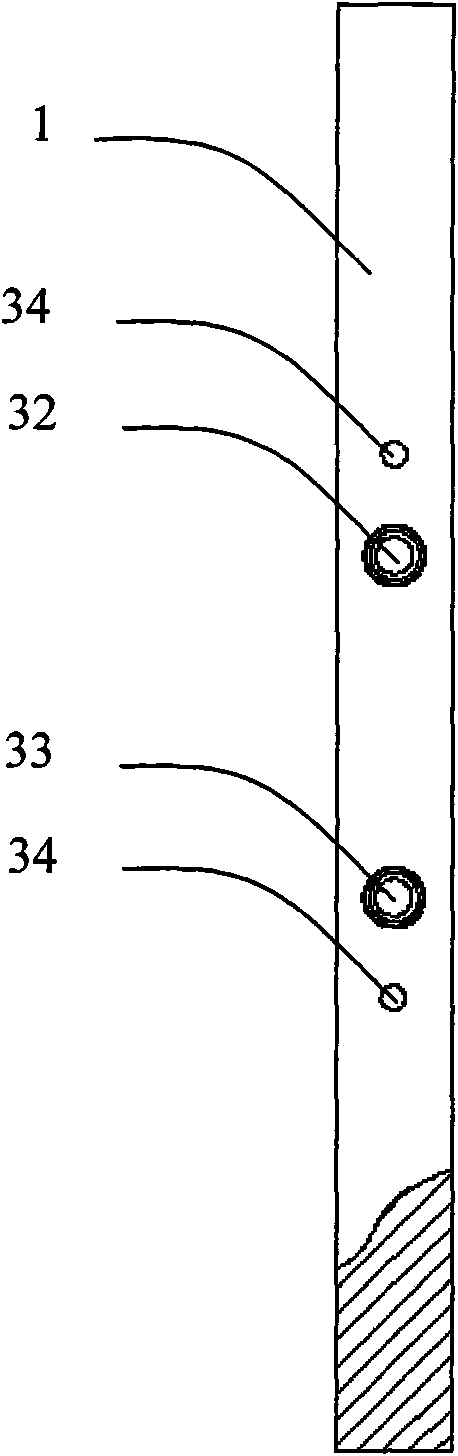

[0028] Such as Figure 1-3 Shown is the high-power module power supply (output power>1000W) of the first embodiment of the present invention. The high-power module power supply 1 includes a casing 10, a circuit board 20, an electrical input connector and an electrical output connector 50, and a heat dissipation structure. Wherein, the casing 10 is provided with a receiving space for accommodating the circuit board 20 ; and the bottom 12 of the casing 10 has a certain thickness and can be used for arranging liquid cooling channels. The circuit board 20 is accommodated in the accommodation space of the housing 10, placed on the inner surface of the bottom 12 of the housing 10, and connected to external equipment through the electrical input connector and the electrical output connector 50 arranged on the side of the housing 10, so as to achieve The purpose of supplying and distributing power to loads. The heat dissipation structure includes a liquid cooling channel 31 formed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com