Separately-excited synchronous motor magnetic flux orientation method

A synchronous motor and magnetic flux technology, applied in the control of generators, motor generators, electronically commutated motors, etc., can solve the problems of easy failure and high cost, avoid motor stall, less hardware, and avoid out of step and oscillating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

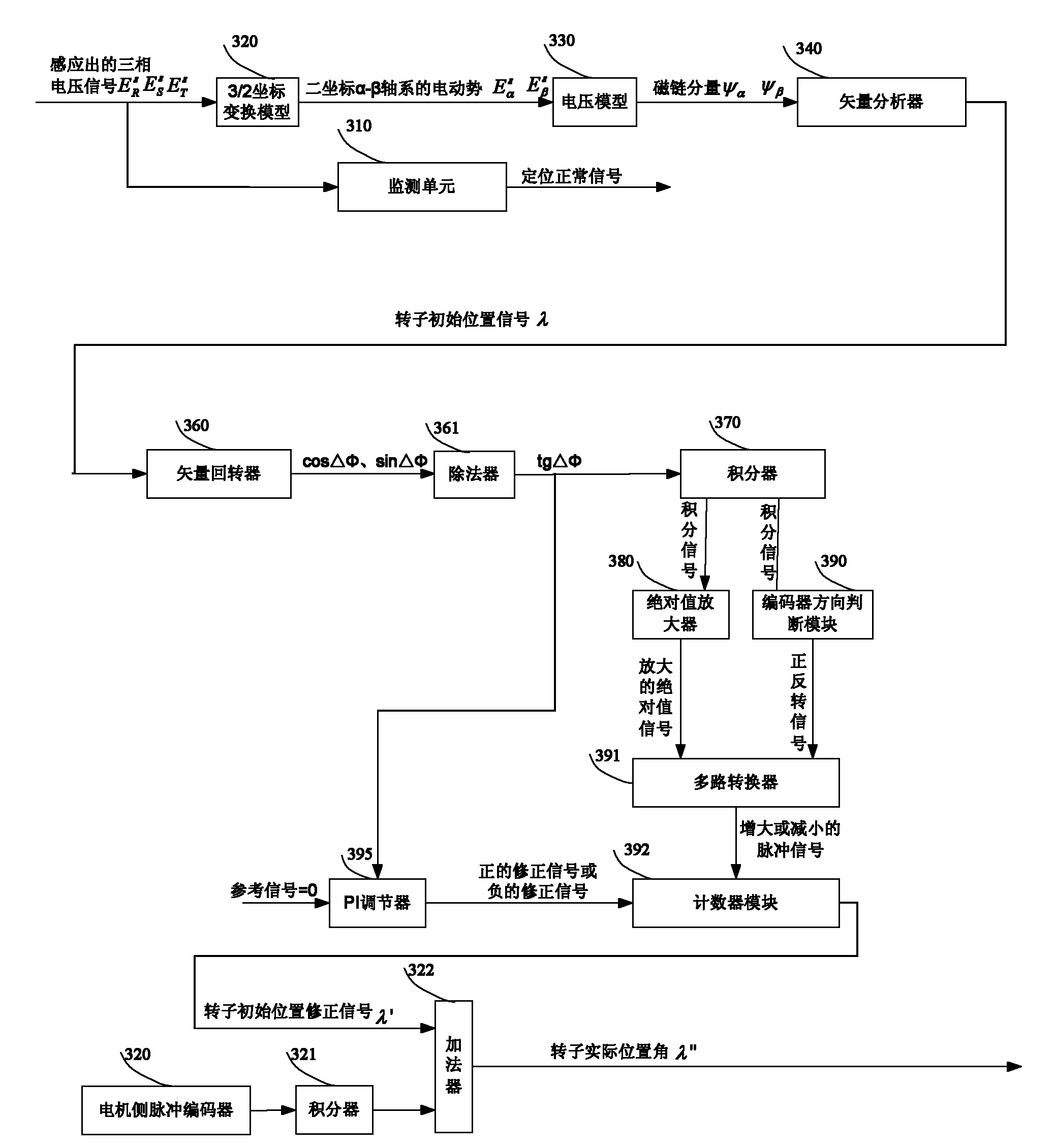

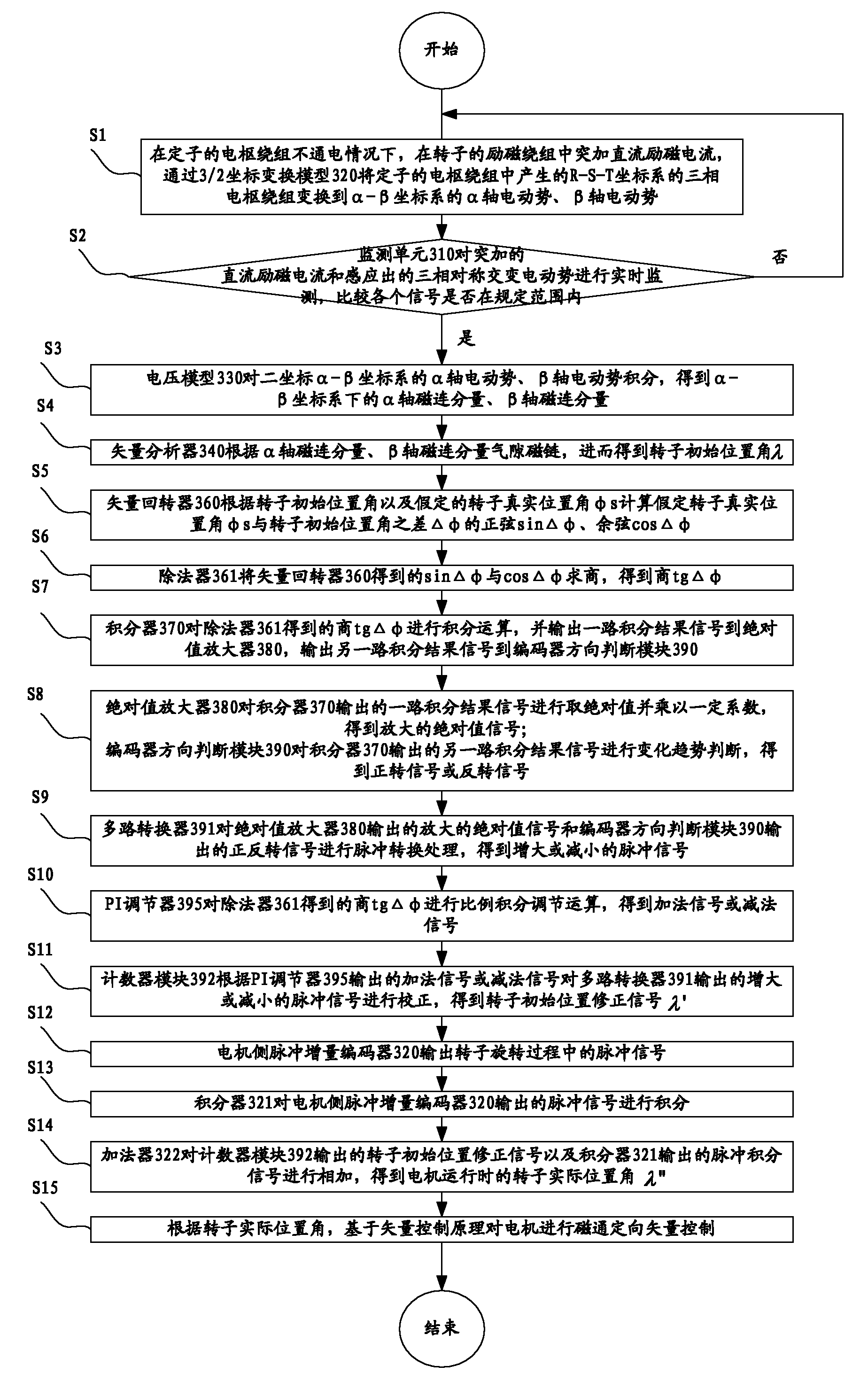

[0035] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

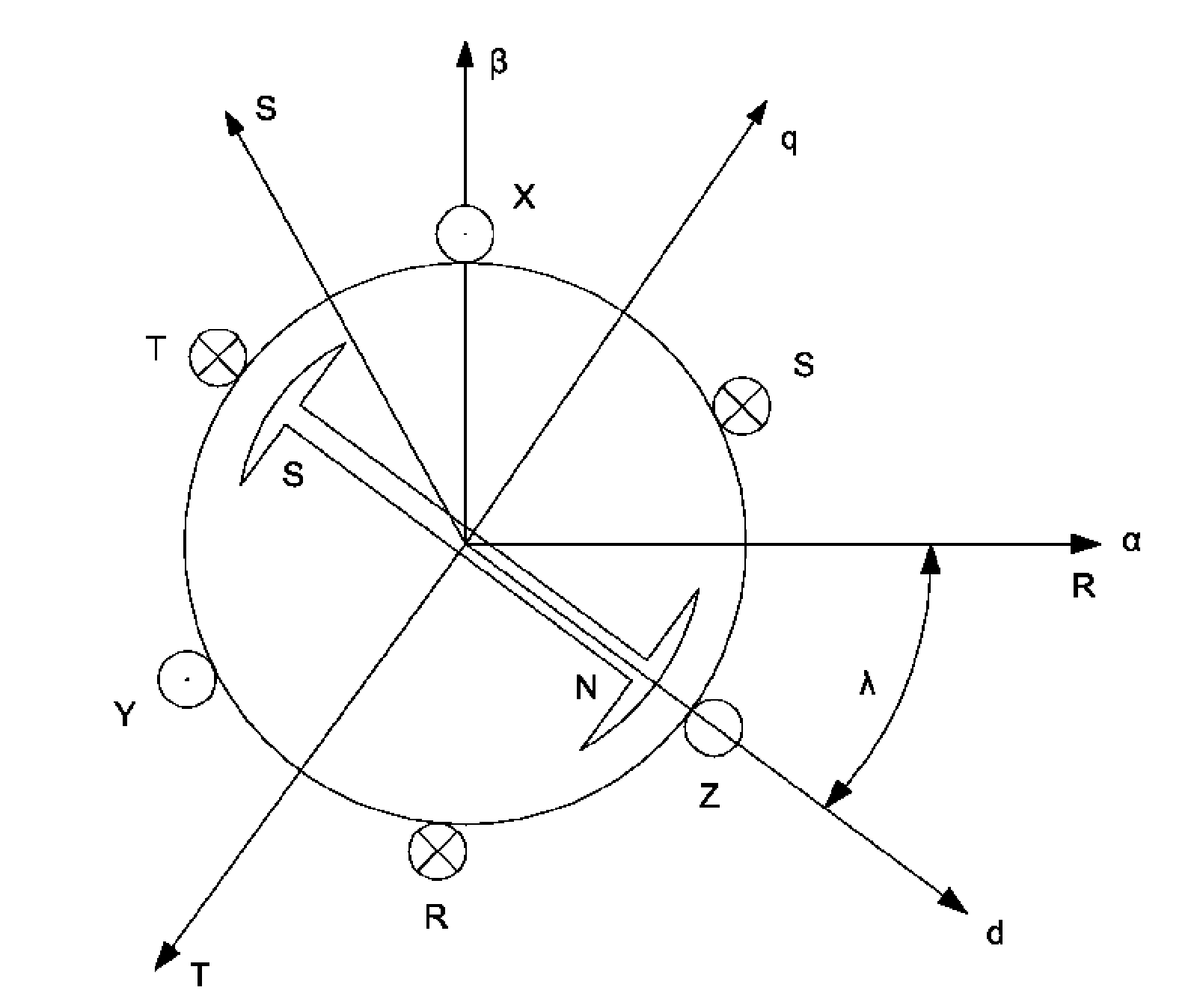

[0036] In order to explain the flux orientation method of the separately excited synchronous motor in this embodiment more clearly, the structure and working principle of the separately excited synchronous motor are described here.

[0037] A generator consists of a rotor and a stator. There are pairs of magnetic poles and field windings on the rotor. There are three-phase symmetrical AC windings (armature windings) on the stator. After the rotor is dragged by the prime mover (hydraulic turbine, steam turbine, diesel engine, etc.), the rotor rotates around the rotor shaft and inputs mechanical energy to the motor; when the excitation winding of the rotor is supplied with DC excitation current, an excitation magnetic field (main magnetic field) is established in the air gap of the motor , the excitation magnetic field ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com