Gas turbine

A technology for gas turbines and combustion exhaust gas, which is applied in the direction of gas turbine devices, mechanical equipment, engine components, etc., and can solve problems such as high manufacturing costs, maintenance and inspection costs, and complex gas turbine systems and applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

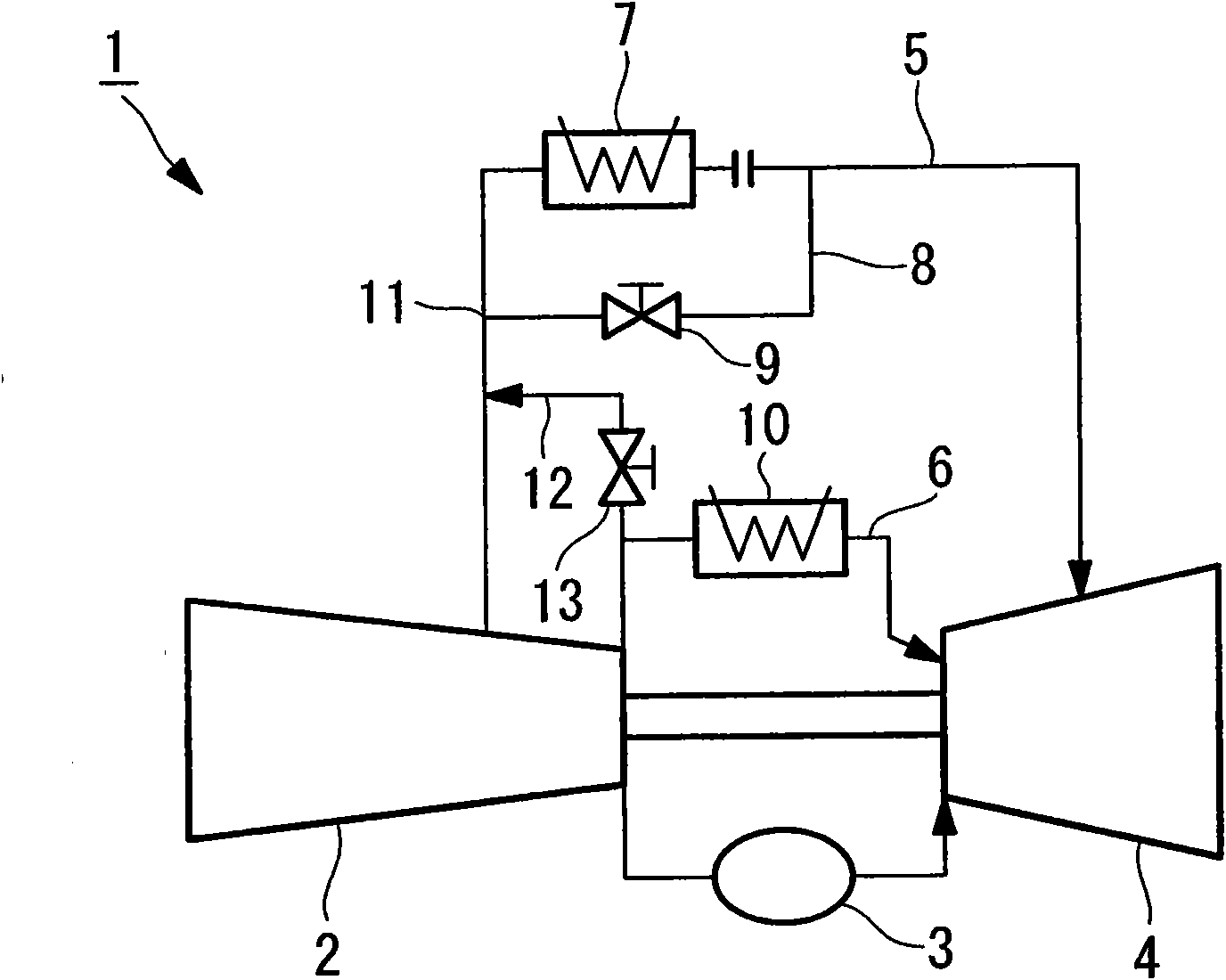

[0120] Below, refer to figure 1 A gas turbine according to a first embodiment of the present invention will be described. figure 1 It is a system diagram of the gas turbine of this embodiment.

[0121] Such as figure 1 As shown, the gas turbine 1 of the present embodiment has, as the main structural elements, a compression unit 2 for compressing combustion air; fuel is injected into the high-pressure air sent from the compression unit 2 and combusted to generate high-temperature combustion exhaust gas. Combustion part 3; Turbine part 4, which is located on the downstream side of the combustion part 3 and is driven by combustion exhaust gas released from the combustion part 3; Gas turbine compartment (not shown shown in the figure); a vane-based cooling air system that guides (medium-pressure) compressed air drawn from the middle (middle stage) of the compression unit 2 into the vanes (for example, second-stage vanes) constituting the turbine unit 3 5. A rotor system cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com