Injection blowing mold for high-capacity plastic hollow container and process method thereof

An empty container, large-capacity technology, which is applied in the field of injection-blowing large-capacity plastic hollow containers and mold equipment for injection-blowing large-capacity plastic hollow containers. , material sagging and other problems, to achieve the effects of easy product quality assurance, accurate centering and positioning, and stable movement and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

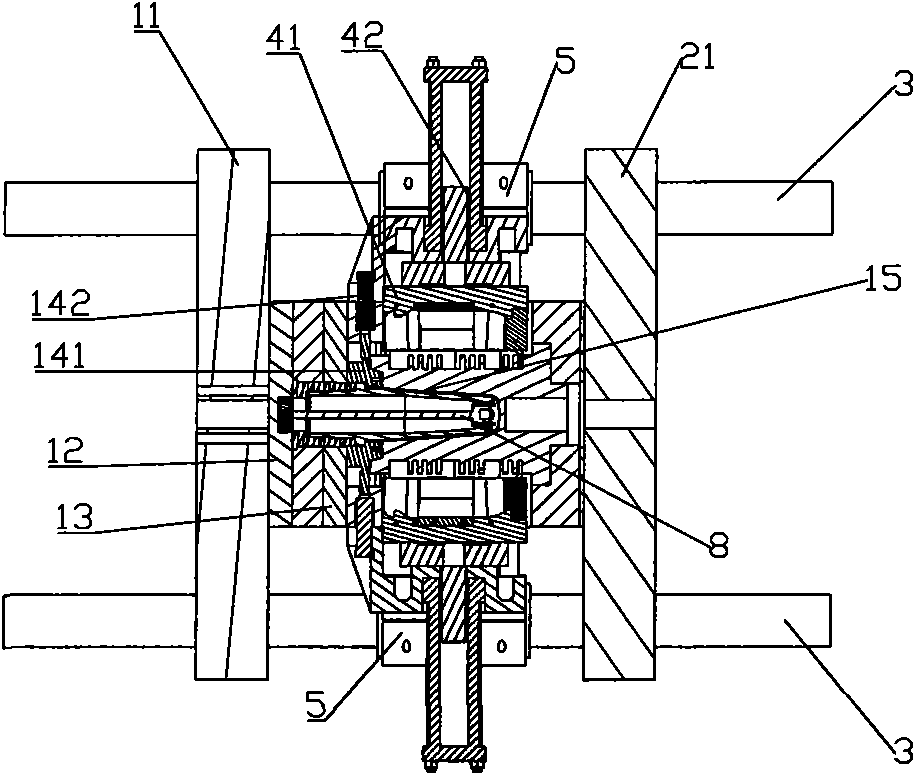

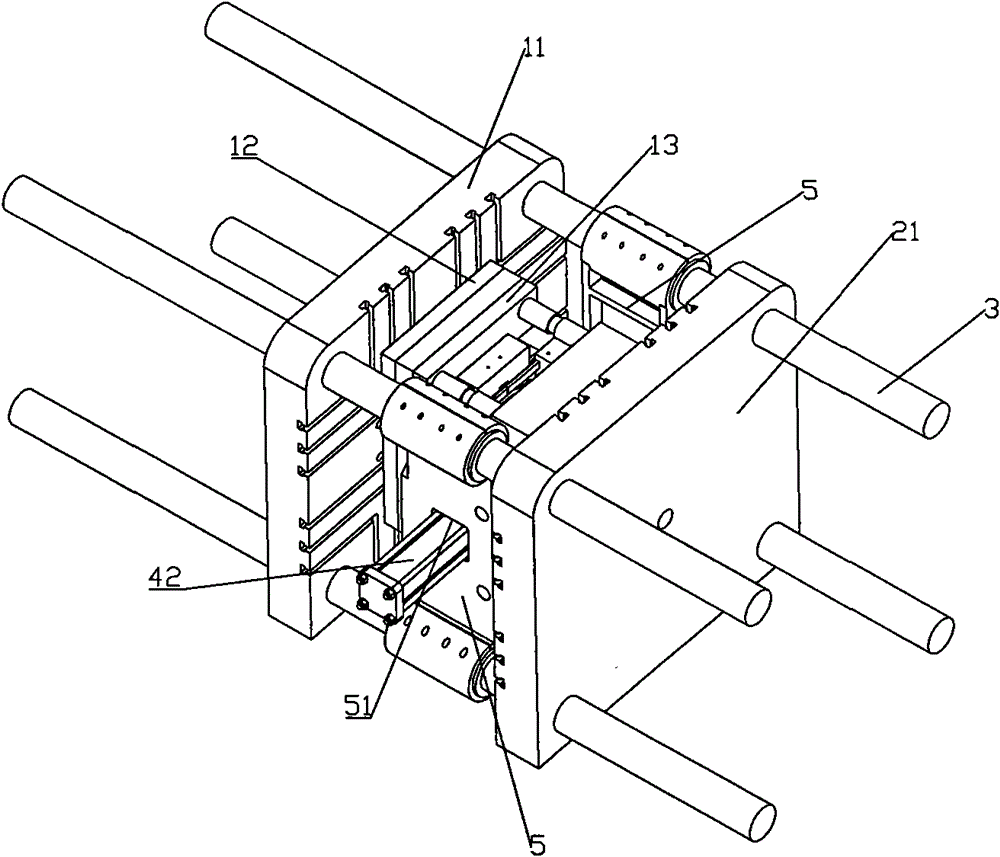

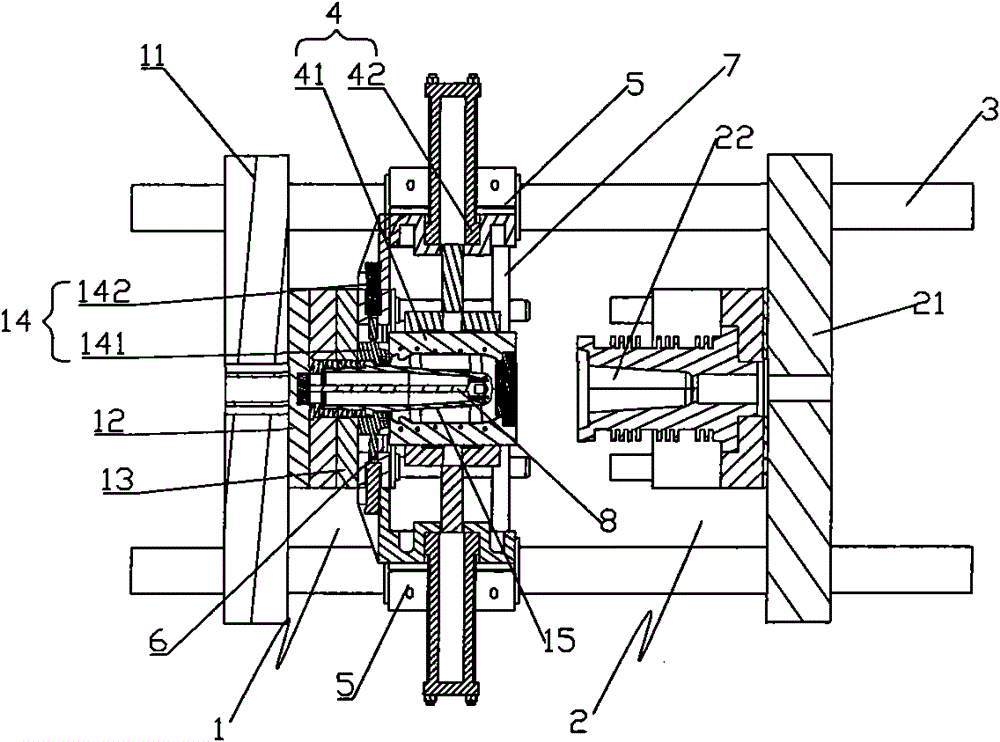

[0031] Such as Figures 1 to 6 As shown, the mold equipment for injection blowing a large-capacity plastic hollow container according to the present invention includes an injection molding machine guide rail 3 , an injection mold assembly and a blow mold assembly 4 .

[0032] The injection mold assembly includes a movable mold 1 and a fixed mold 2 arranged parallel to the left and right, the movable mold 1 is installed on the movable template 11 of the injection molding machine, the fixed mold 2 is fixed on the fixed template 21 of the injection molding machine, and the movable mold 1 It is driven by a group of driving devices to move left and right along the guide rail 3 of the injection molding machine, so as to realize the opening and closing of the movable mold 1 and the fixed mold 2 .

[0033] The fixed mold 2 is provided with an injection parison concave mold 22 .

[0034] The movable mold 1 includes an air inlet plate 12 , a push plate 13 , a container thread forming ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com