Pre-stacking device of hydraulic electromagnetic steel plates

A technology of electromagnetic steel plate and hydraulic lifting device, which is applied to the stacking, transportation and packaging of objects, and conveyor objects, etc., which can solve the problems of large equipment structure, large floor area, and low stacking accuracy, and achieve the goal of maintaining stacking Accuracy, convenient operation and accurate position movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

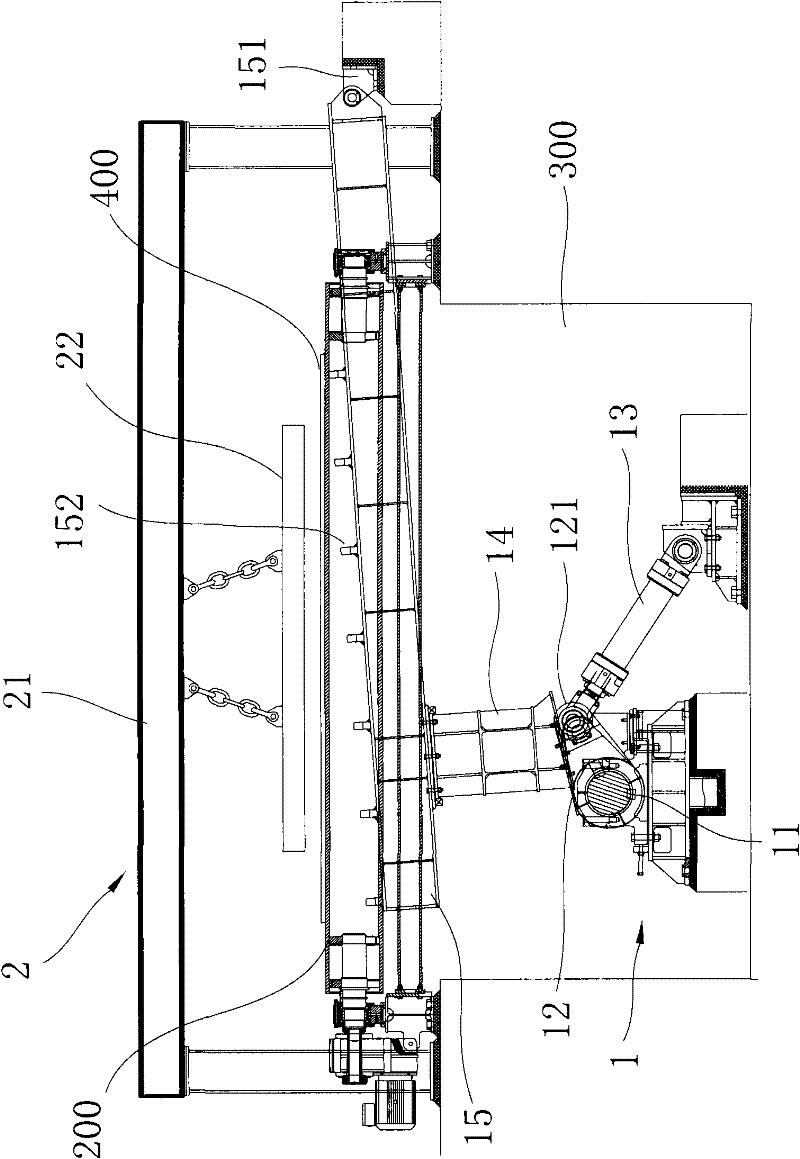

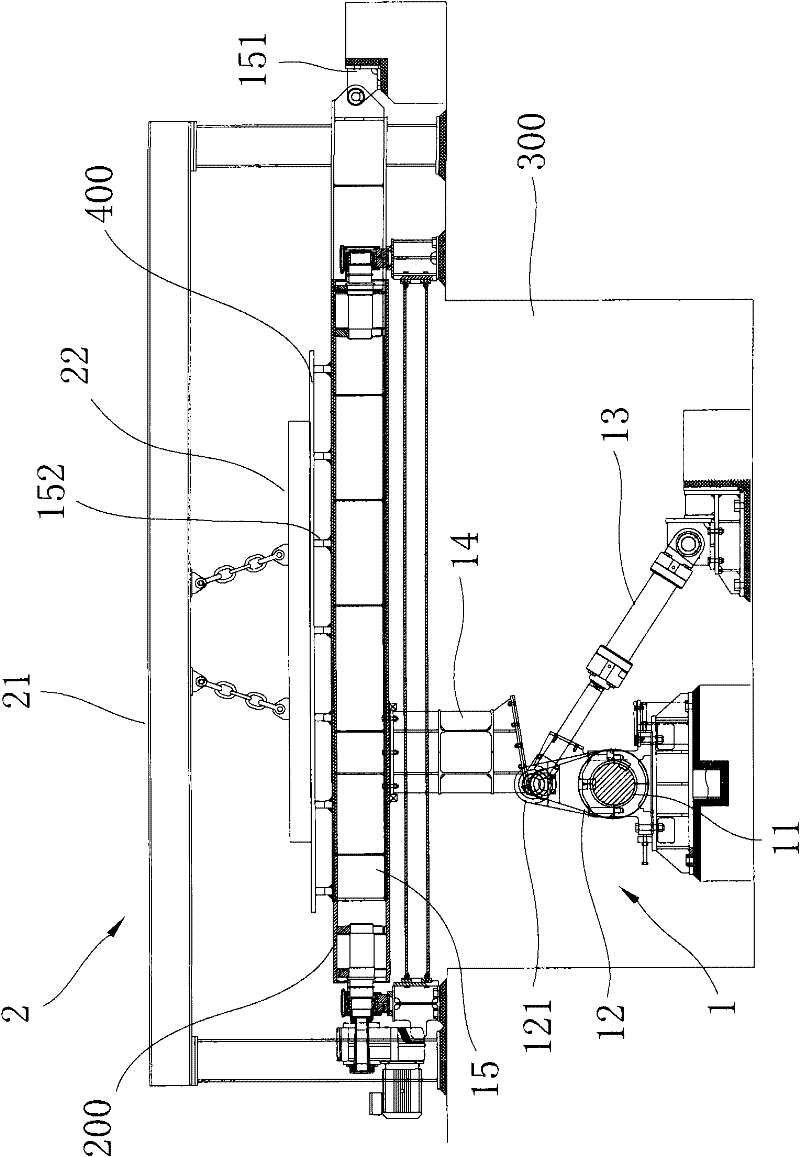

[0052] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. The hydraulic electromagnetic steel plate pre-stacking device of the present invention can be applied to a variety of working environments and can pre-stack steel plates of various specifications, among which the pre-stacking of medium-thick steel plates is the most typical, and the following is only stacked on the conveying roller table The steel plate is described as a preferred embodiment, but it is not limited thereto.

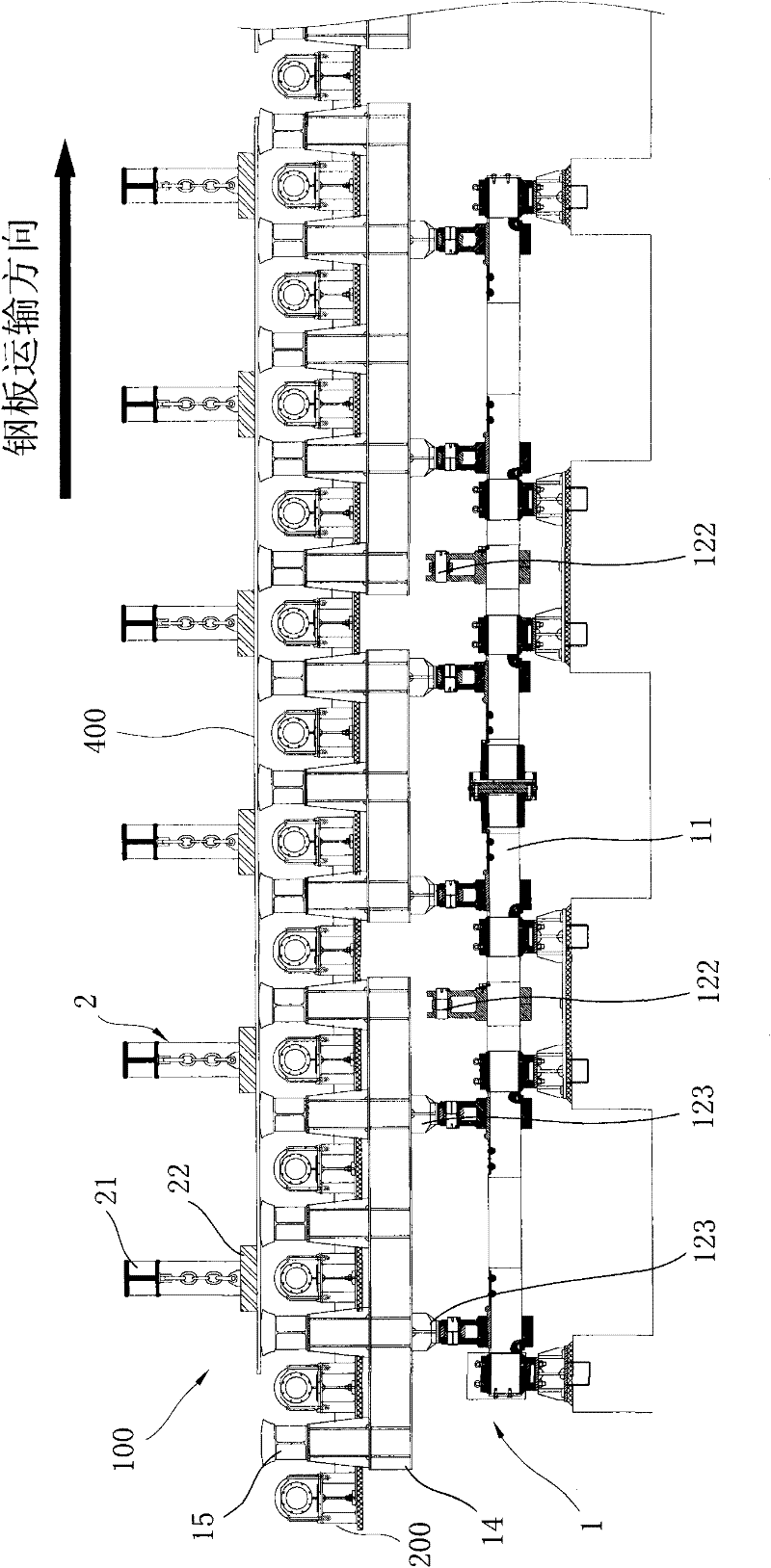

[0053] Please refer to figure 1 , is a schematic front view of the overall structure of the hydraulic electromagnetic steel pre-stacking device of the present invention. As shown in the figure, the entire hydraulic electromagnetic pre-stacking device 100 is interspersed with the transmission roller table 200, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com