Method for producing nisin by continuous fermentation

A technology of nisin and nisin, which is applied in the field of continuous fermentation to produce nisin, which can solve the problems of non-optimal economic stage of operation time, reduced equipment utilization rate, and increased production cost, so as to improve equipment utilization rate , reduce production costs, increase the effect of fermentation yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

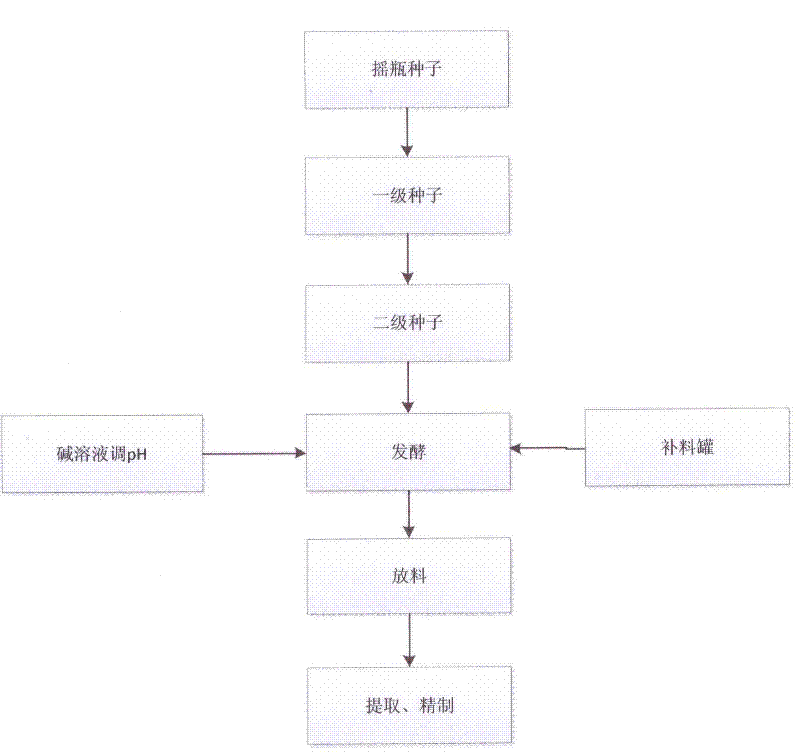

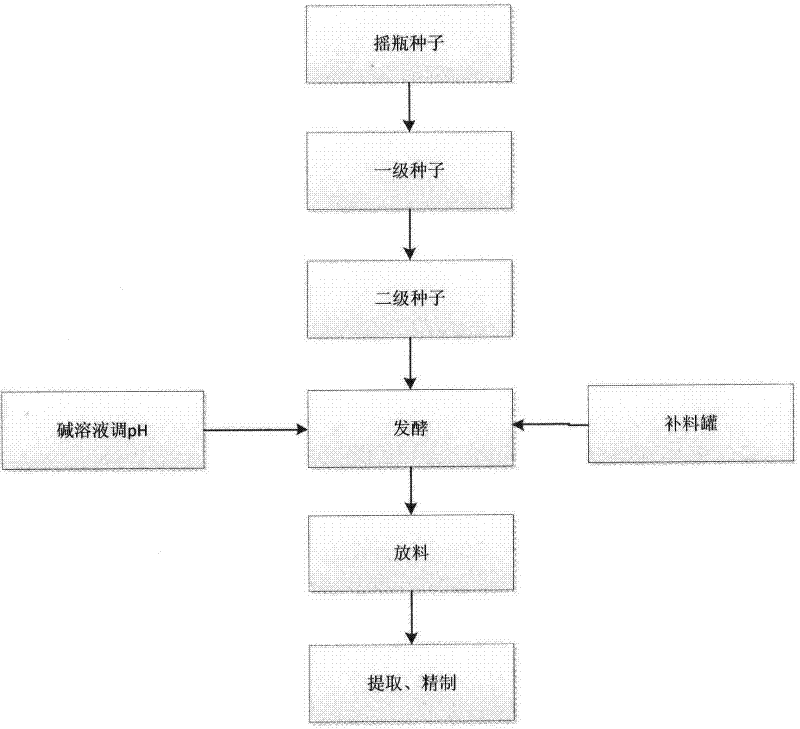

Method used

Image

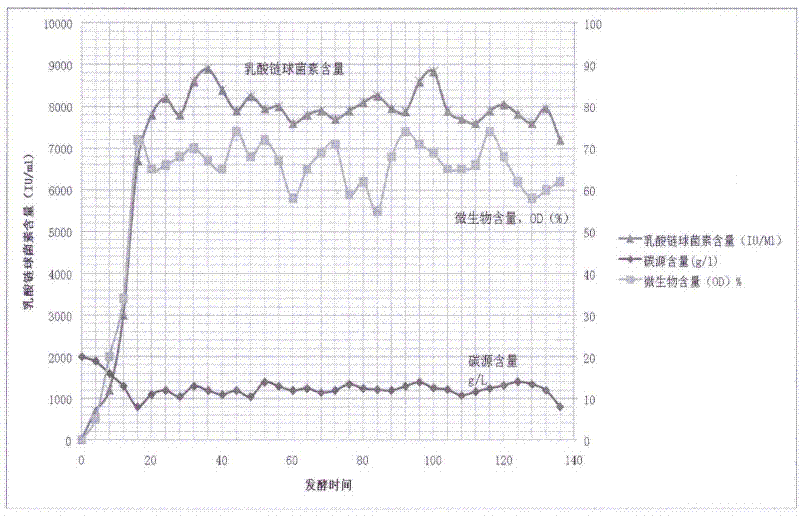

Examples

Embodiment 1

[0030] 1. Primary seed preparation

[0031] The first-level seed tank is 200 liters, and the filling capacity is 150 liters. The seed medium is prepared according to the following ratio:

[0032] Glucose: 10 g / l,

[0033] Sucrose: 10 g / l,

[0034] Yeast extract: 7 g / l,

[0035] Dipotassium hydrogen phosphate: 12 g / L,

[0036] Corn syrup: 5 g / L,

[0037] Magnesium sulfate: 0.2 g / l

[0038] 5% sodium hydroxide solution to adjust the pH to 7.2,

[0039] Sterilization: 120°C for 30 minutes, cooling to 32°C, differential pressure inoculation seed solution: 2 liters, sterile air to maintain a pressure of 0.2MPa, and culture for 16 hours.

[0040] Second, secondary seed preparation

[0041] The secondary seed tank is 2000 liters, and the filling capacity is 1500 liters. The seed medium is prepared according to the following ratio:

[0042] Glucose: 10 g / l,

[0043] Sucrose: 10 g / l,

[0044] Yeast extract: 7 g / l,

[0045] Corn syrup: 5 g / L,

[0046] Dipotassium hydrogen ph...

Embodiment 2

[0071] 1. Primary seed preparation

[0072] The first-level seed tank is 200 liters, and the filling capacity is 150 liters. The seed medium is prepared according to the following ratio:

[0073] Sucrose: 10 g / l,

[0074] Glucose: 5 g / L

[0075] Yeast extract: 5 g / l,

[0076] Corn syrup: 5 g / L,

[0077] Magnesium sulfate: 0.2 g / l

[0078] Dipotassium hydrogen phosphate: 15 g / L

[0079] 5% potassium hydroxide solution to adjust the pH to 7.0,

[0080] Sterilization: 120°C for 30 minutes, cooling to 32°C, differential pressure inoculation seed solution: 2 liters, sterile air to maintain a pressure of 0.2MPa, and culture for 24 hours.

[0081] Second, secondary seed preparation

[0082] The secondary seed tank is 2000 liters, and the filling capacity is 1500 liters. The seed medium is prepared according to the following ratio:

[0083] Sucrose: 10 g / l,

[0084] Glucose: 5 g / L

[0085] Yeast extract: 5.0 g / l,

[0086] Corn syrup: 5.0 g / L,

[0087] Dipotassium hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com