Continuous loose fiber dyeing machine

A dyeing machine and dyeing cylinder technology, applied in the field of dyeing machines, can solve problems such as being unfavorable for large roll work, waste dyes, and large roll workload, etc., and achieve the effects of improving dye penetration, saving consumption and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

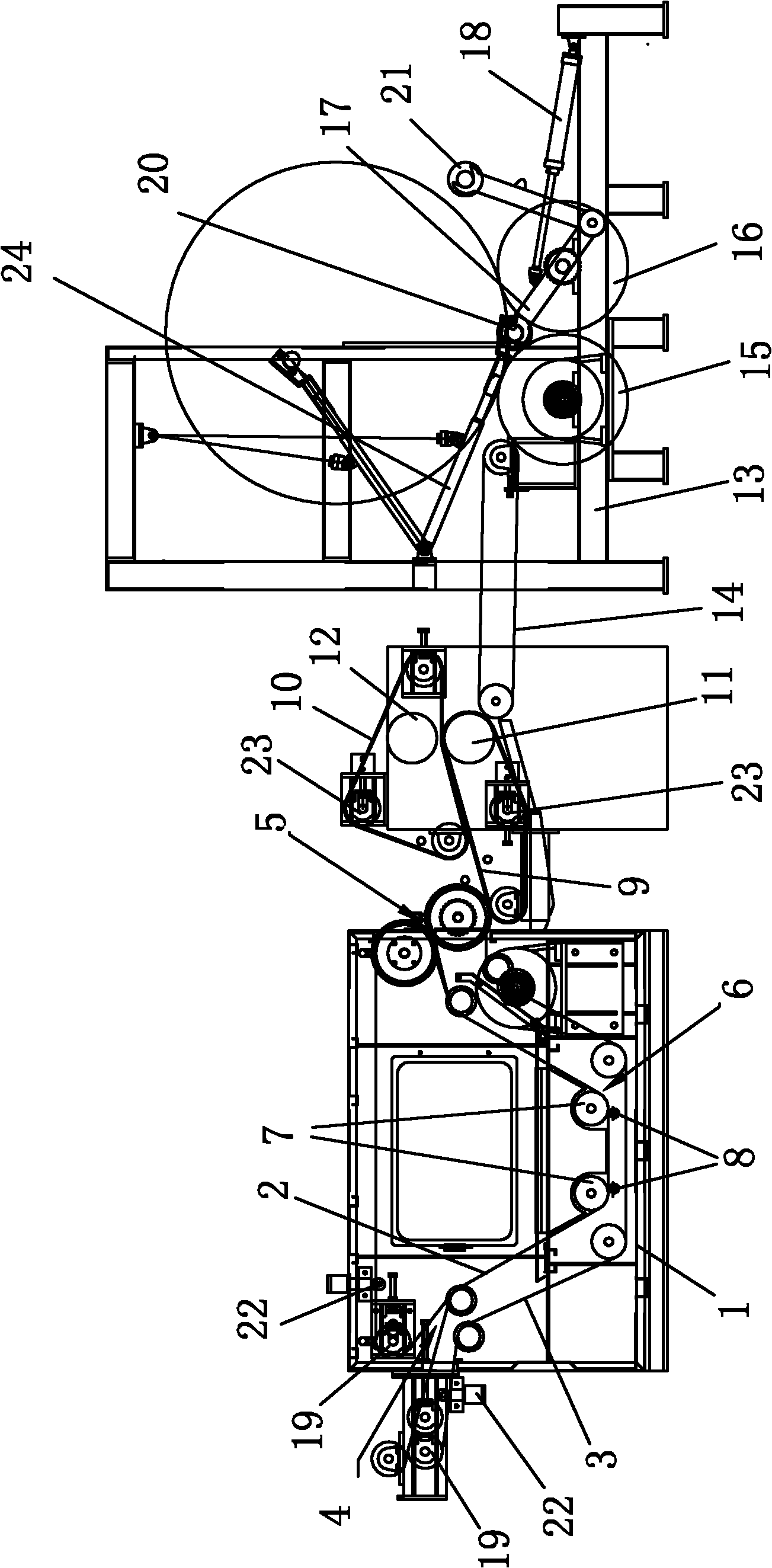

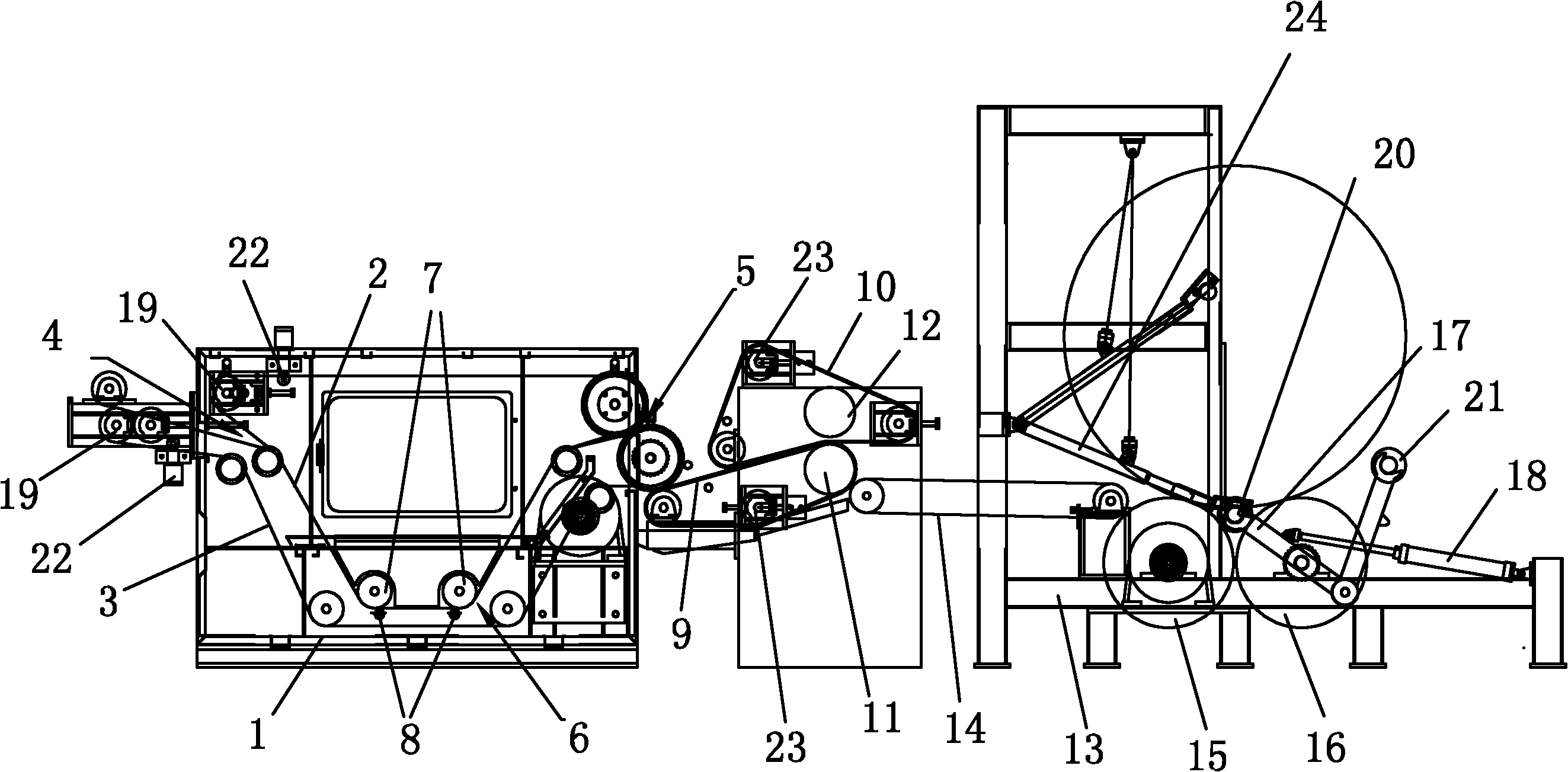

[0016] Example: Continuous bulk fiber dyeing machine, such as figure 1 As shown, it includes a dyeing vat 1, and the mechanism for conveying loose fibers matched with the dyeing vat 1 is a double-mesh belt dyeing conveying mechanism, which includes two closed endless mesh belts A2 and endless mesh belt B3, The transmission components that are respectively matched with the transmission of each dyeing mesh belt, the two ring-shaped dyeing mesh belts located in the dyeing vat 1 are interstitially stacked and matched, and the two ring-shaped dyeing mesh belts that are respectively matched with the inlet and outlet ends of the dyeing vat 1 A duckbill-shaped input port 4 and a duckbill-shaped output port 5 are respectively formed, and two ring-shaped dyeing mesh belts located outside the dyeing vat 1 cooperate with respective transmission components to form a ring-shaped transmission. The loose fiber is clamped and transported to the dyeing vat by the double mesh belt dyeing conveyi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com