Method for constructing artificial dug pile at reduced well point ground water level

A technology for artificially digging hole piles and groundwater levels, which is applied in sheet pile walls, foundation structure engineering, construction, etc., to avoid high cost investment, improve construction efficiency and safety guarantee factor, and reduce costs and operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0018] The present invention fully considers meeting the design requirements of manual-dug piles, and sets precipitation wells near the manual-dug piles for centralized drainage to provide a construction environment where there is basically no groundwater when constructing manual-dug piles. When constructing manual-dug piles, 120mm Thick concrete zigzag retaining wall, pile body concrete pouring does not require high cost investment of underwater pouring concrete.

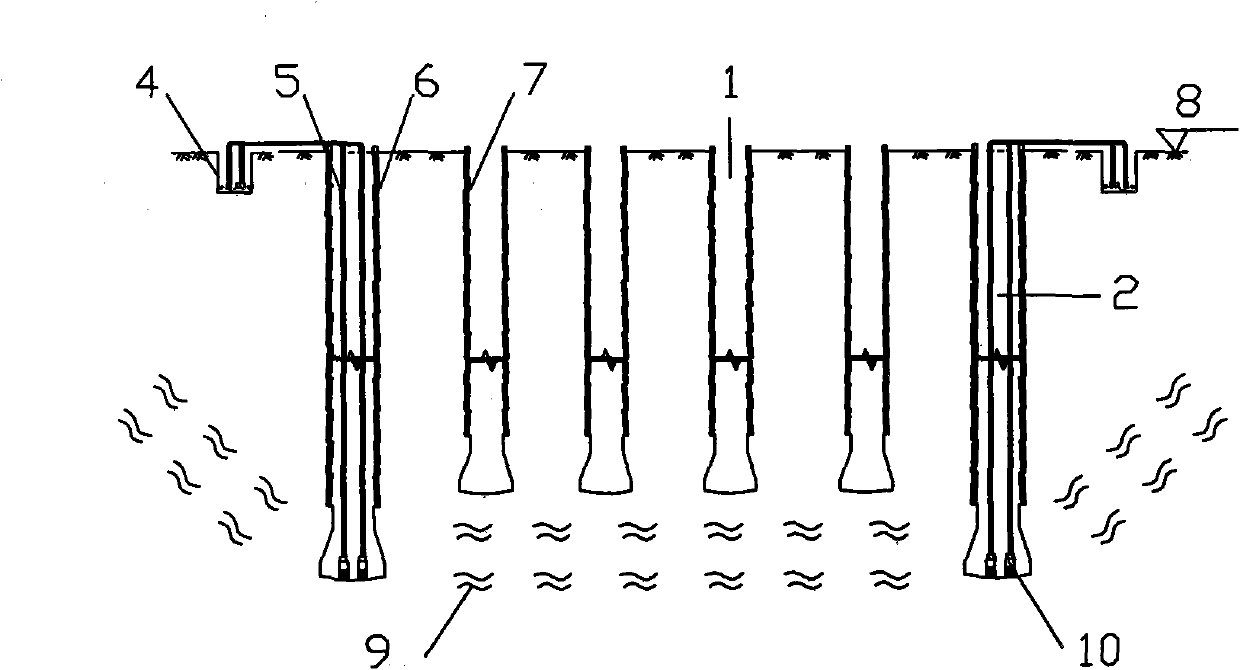

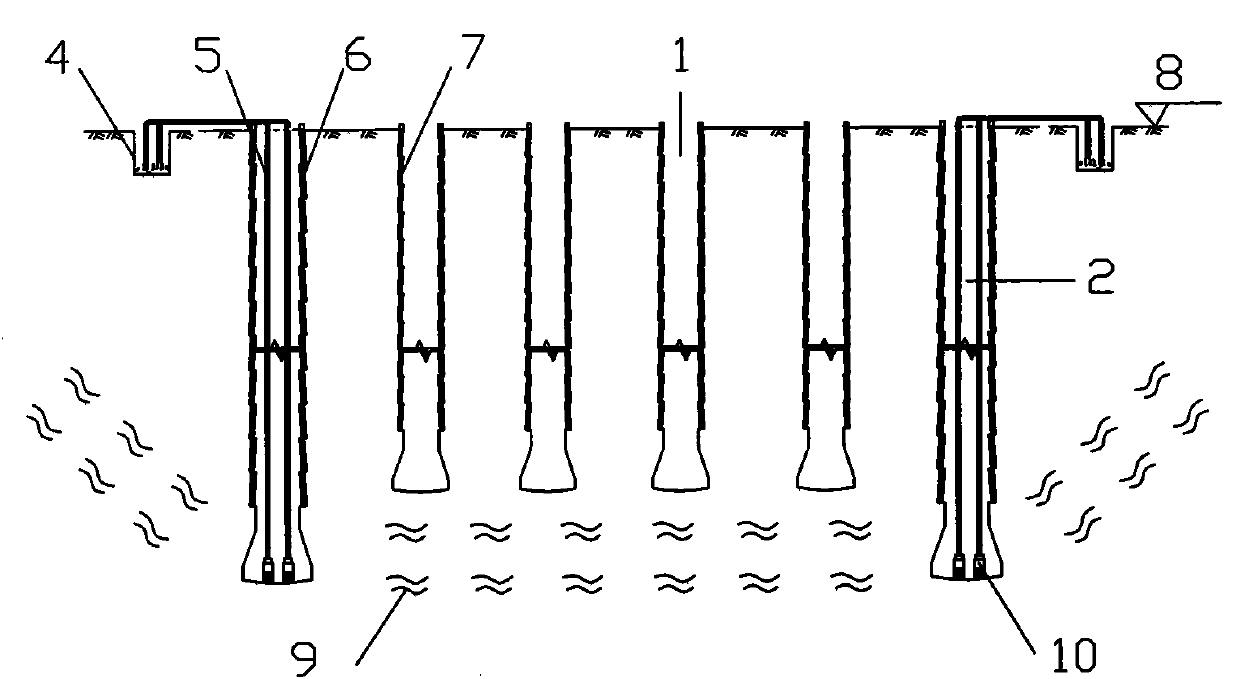

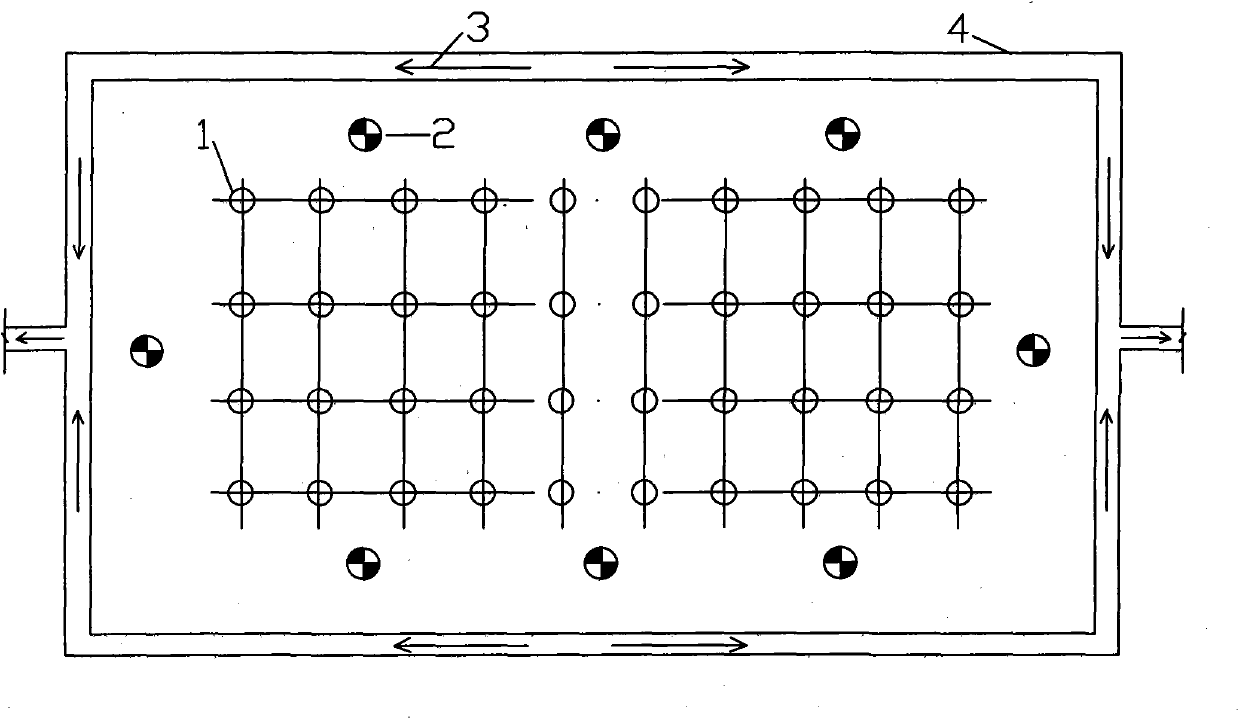

[0019] refer to figure 1 , figure 2 , a kind of well point of the present invention lowers the method for underground water level construction manual hole digging pile and the concrete steps are:

[0020] 1) Set dra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com