Carbon fiber heating source and heating system using the same

A carbon fiber heating and heating system technology, used in electric heating systems, heating systems, heating methods, etc., can solve the problems of carbon fiber impact resistance and weak tension, carbon fiber cannot be bent or folded, and resistance is easily broken or damaged. High tensile strength, oxidation prevention, high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The advantages, features and aspects of the present invention will become apparent from the description of the following embodiments with reference to the accompanying drawings. A description of the embodiments will be set forth below.

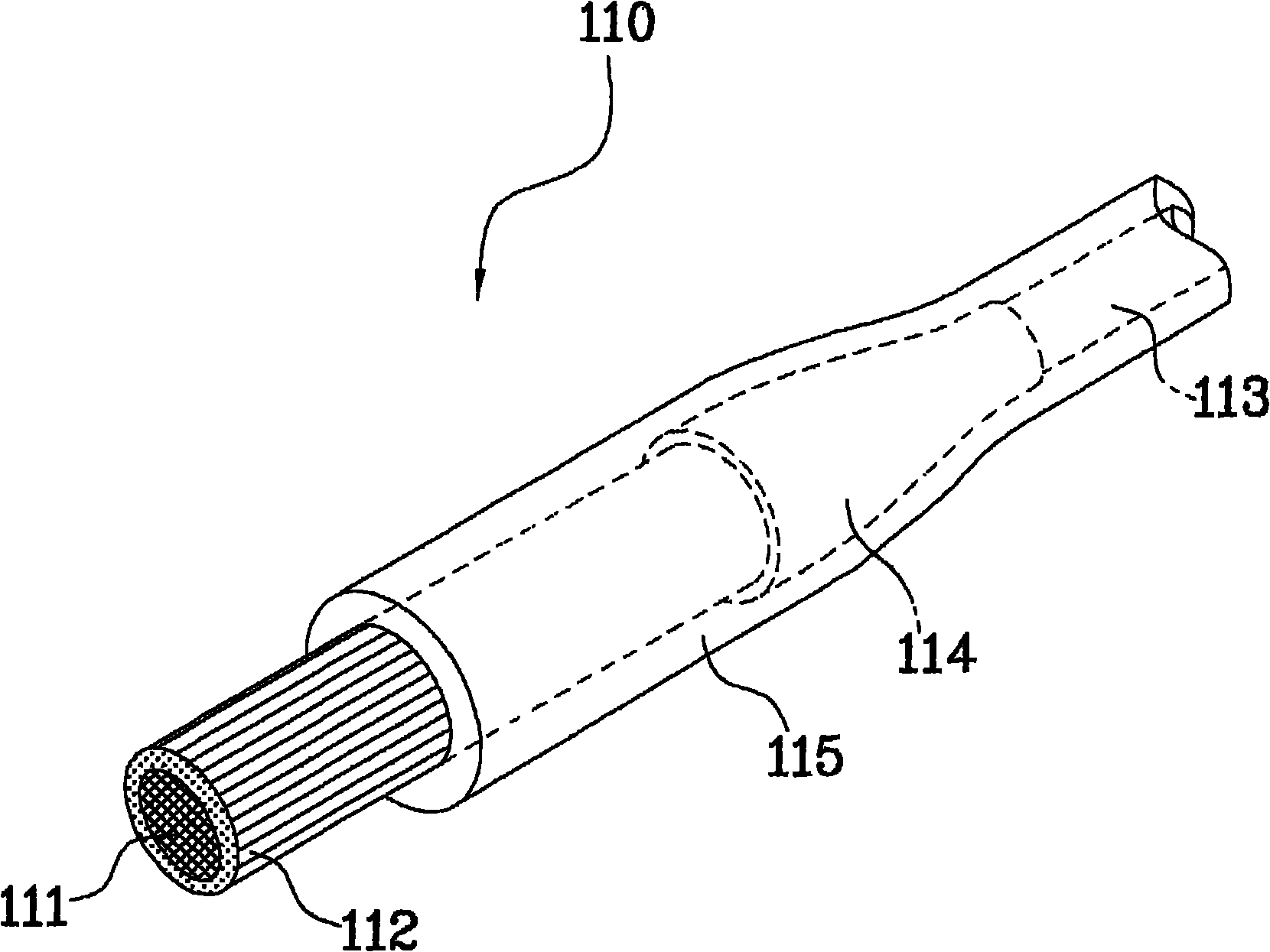

[0073] figure 1 It is a perspective view of a carbon fiber heating source according to an embodiment of the present invention.

[0074] Such as figure 1 As shown, the carbon fiber heating source 110 is formed by a bundle of two or more strands of carbon fiber 111 , and the carbon fiber 111 generates heat at high temperature after power is applied and has a predetermined length. When a bundle of carbon fibers 111 is provided, a predetermined number of glass fibers 112 having the same length are combined with the carbon fibers 111 .

[0075] According to the combination of carbon fiber 111 and glass fiber 112 , glass fiber 112 having high tensile strength against external force including tension or bending force applied to both sides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com