Cylinder

A cylinder rod and sensor technology, applied in the field of cylinders, can solve problems such as unfavorable maintenance and high cost of cylinder manufacturing, and achieve the effects of reducing production costs and reducing leakage magnetic fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

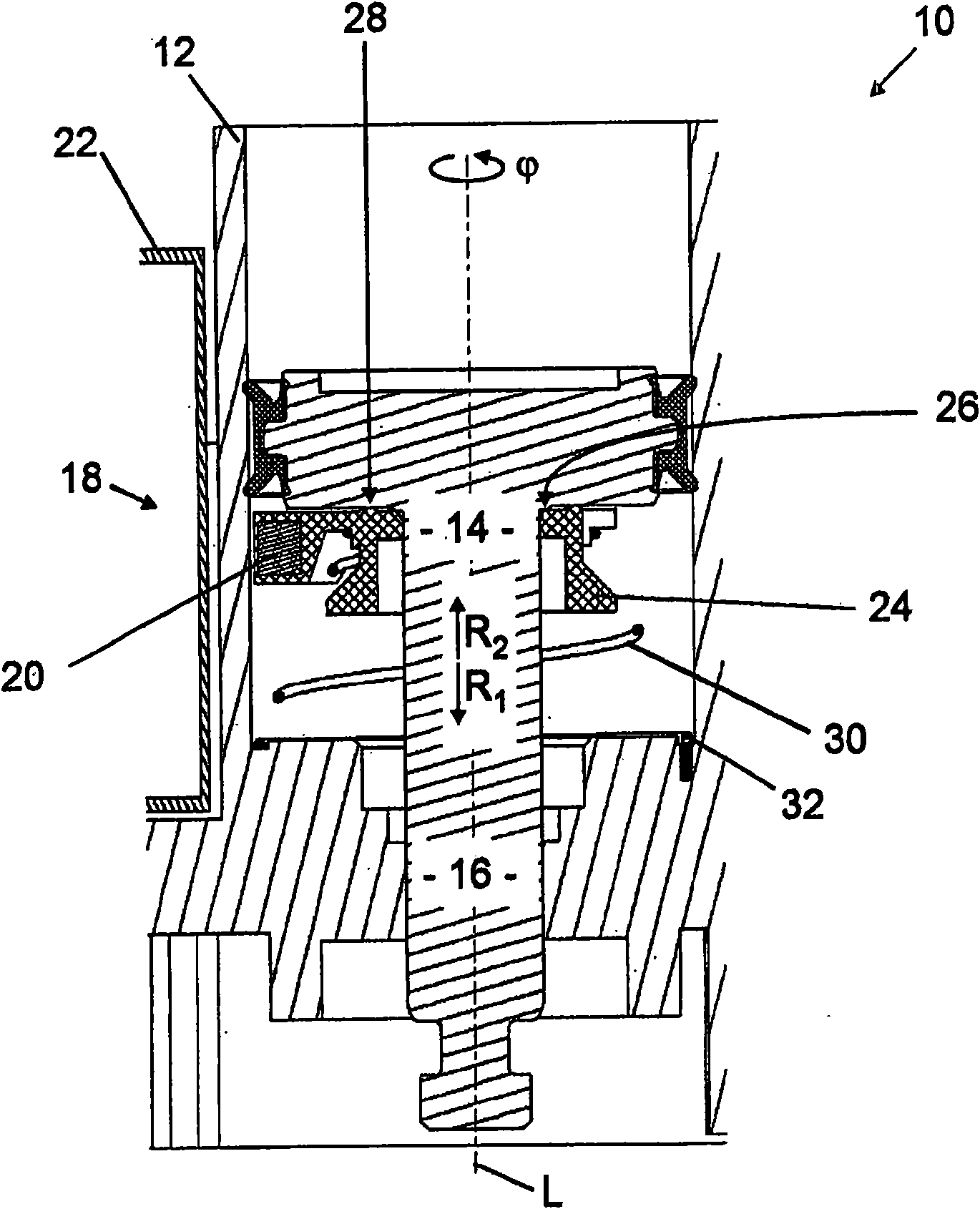

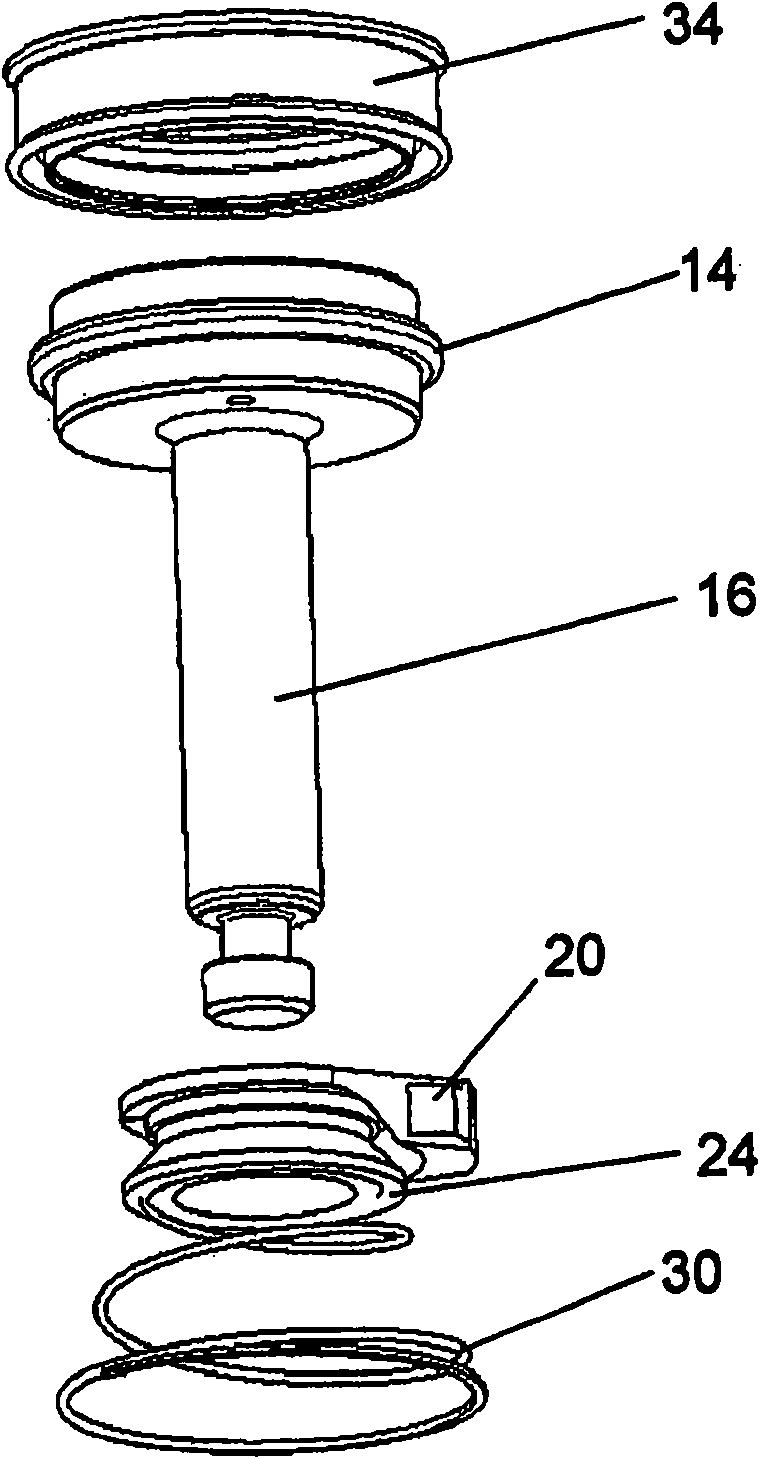

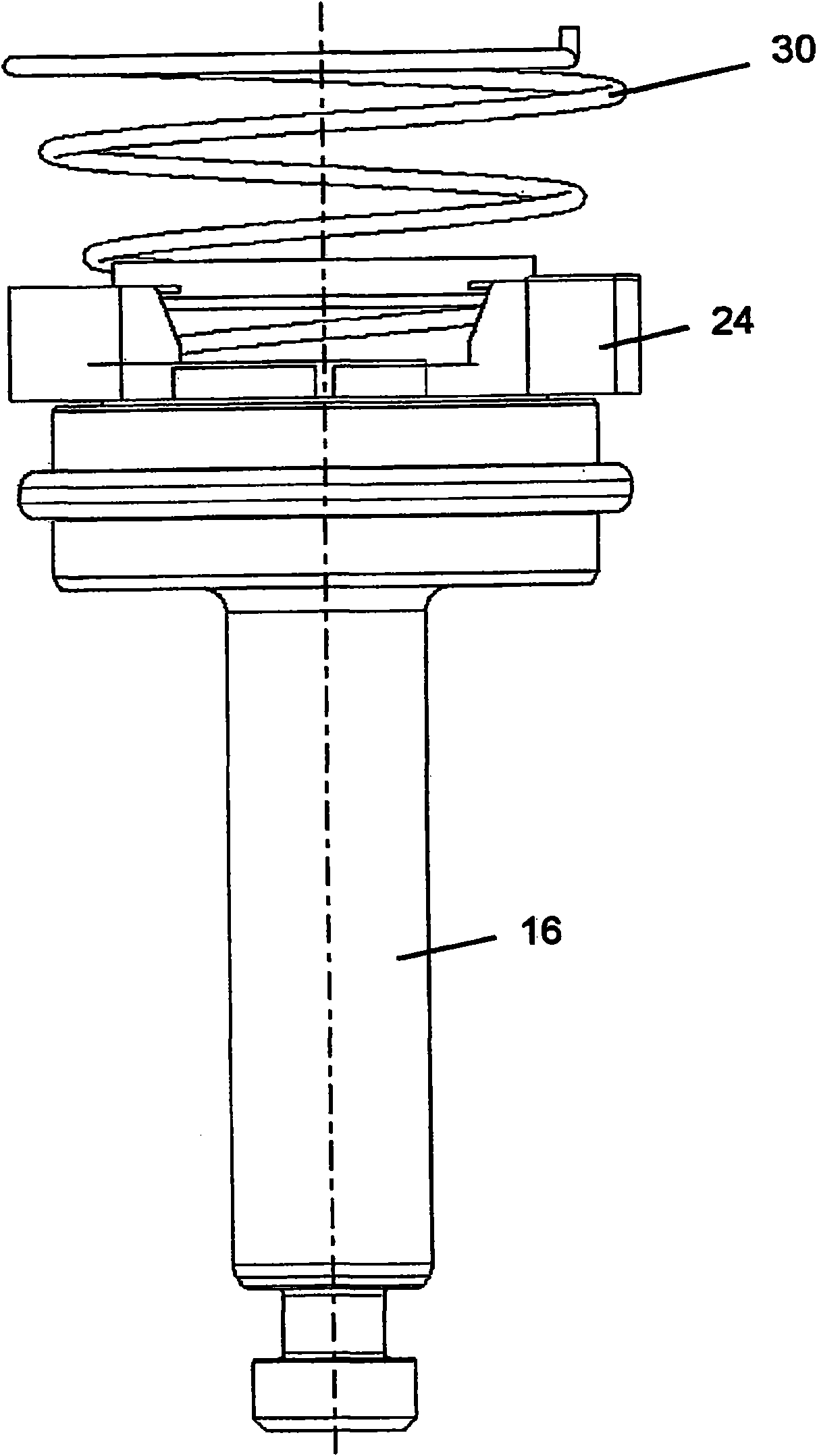

[0025] figure 1 A cylinder 10 is shown with a piston 14 running in a cylinder housing 12 , which is fastened on a cylinder rod 16 and is fixed rotatably about a cylinder rod longitudinal axis L .

[0026] Furthermore, the cylinder 10 comprises a position sensor 18 comprising a sensor magnet 20 and a sensor element 22 cooperating with the sensor magnet 20 . The position sensor 18 is designed in such a way that the position sensor 18 detects the position of the piston 14 at a height relative to the longitudinal axis L of the cylinder rod.

[0027] The piston 14 is rotatable about the longitudinal axis L through an angle of rotation with respect to the cylinder housing 12 The sensor magnet 20 is always arranged opposite the sensor element 22 with respect to the cylinder housing 12 in that the sensor magnet 20 is arranged in a rotationally fixed manner with respect to the cylinder housing 12 . Furthermore, the sensor magnet 20 is fixed on the adapter 24 . For example, the sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com