Heavy-load numerical control rotating table

A technology of rotary table and table, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor static and dynamic rigidity of the rotary table and vibration of the table, and achieve good static rigidity, eliminate vibration, Good dynamic rigidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In the following, the present invention will be further described by using the following embodiments in conjunction with the accompanying drawings.

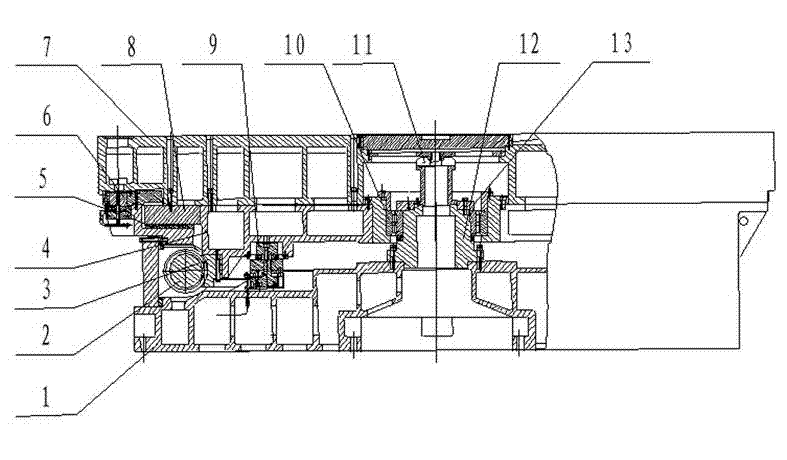

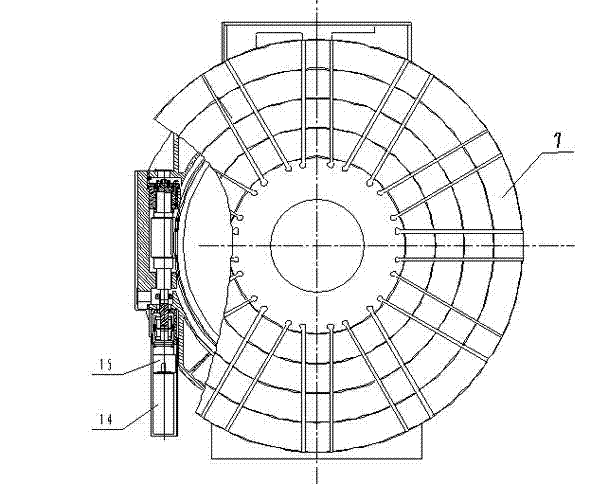

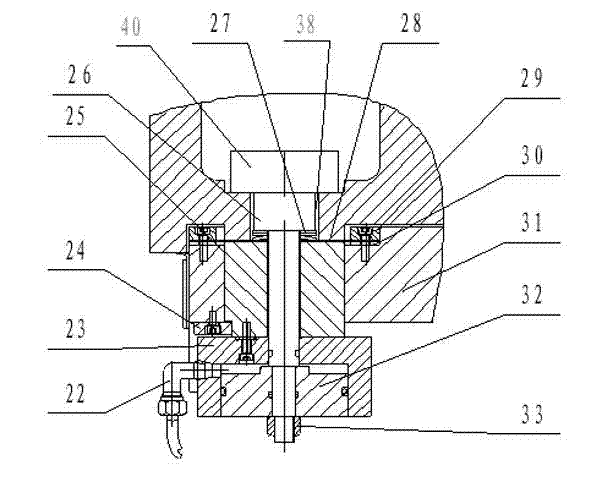

[0028] Such as figure 1 , 2 Shown is the specific structure of the present invention, which is a large-scale heavy-duty CNC rotary table, including a turntable body 1, a worktable 7, a worm gear frame 4, a worm wheel 3, a worm 2, a servo motor 14, a reducer 15, and an angle code Device 11, main shaft bearing 10, guide rail 8, guide rail plate 5, main shaft 12, static locking system 6, damping dynamic vibration elimination system 9. The turntable body is connected with the bed of the main machine, and the workbench 7 is arranged on the body through the ring guide rail 8 .

[0029] The turntable body is the basic part of the rotary table, which must have sufficient rigidity and strength. Ribs are arranged in the middle and lower part of the turntable body 1 along the circumferential and longitudinal directions, and plastic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com