Jumping robot of locust-simulated turning joint lever ejecting mechanism

A technology of movable joints and robots, which is applied to motor vehicles, transportation and packaging, etc., to achieve the effects of improving energy utilization, reducing costs, and reducing body weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

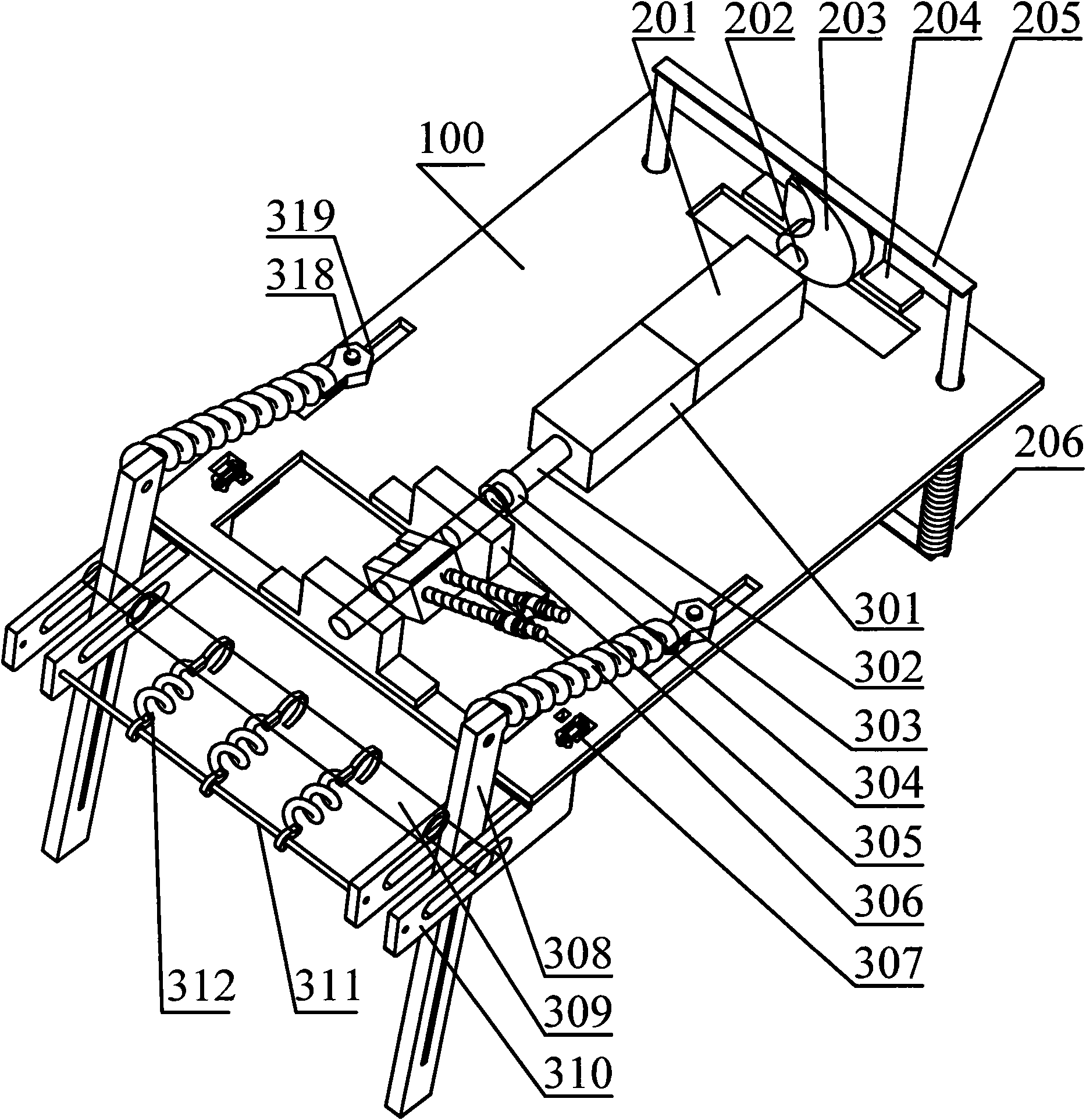

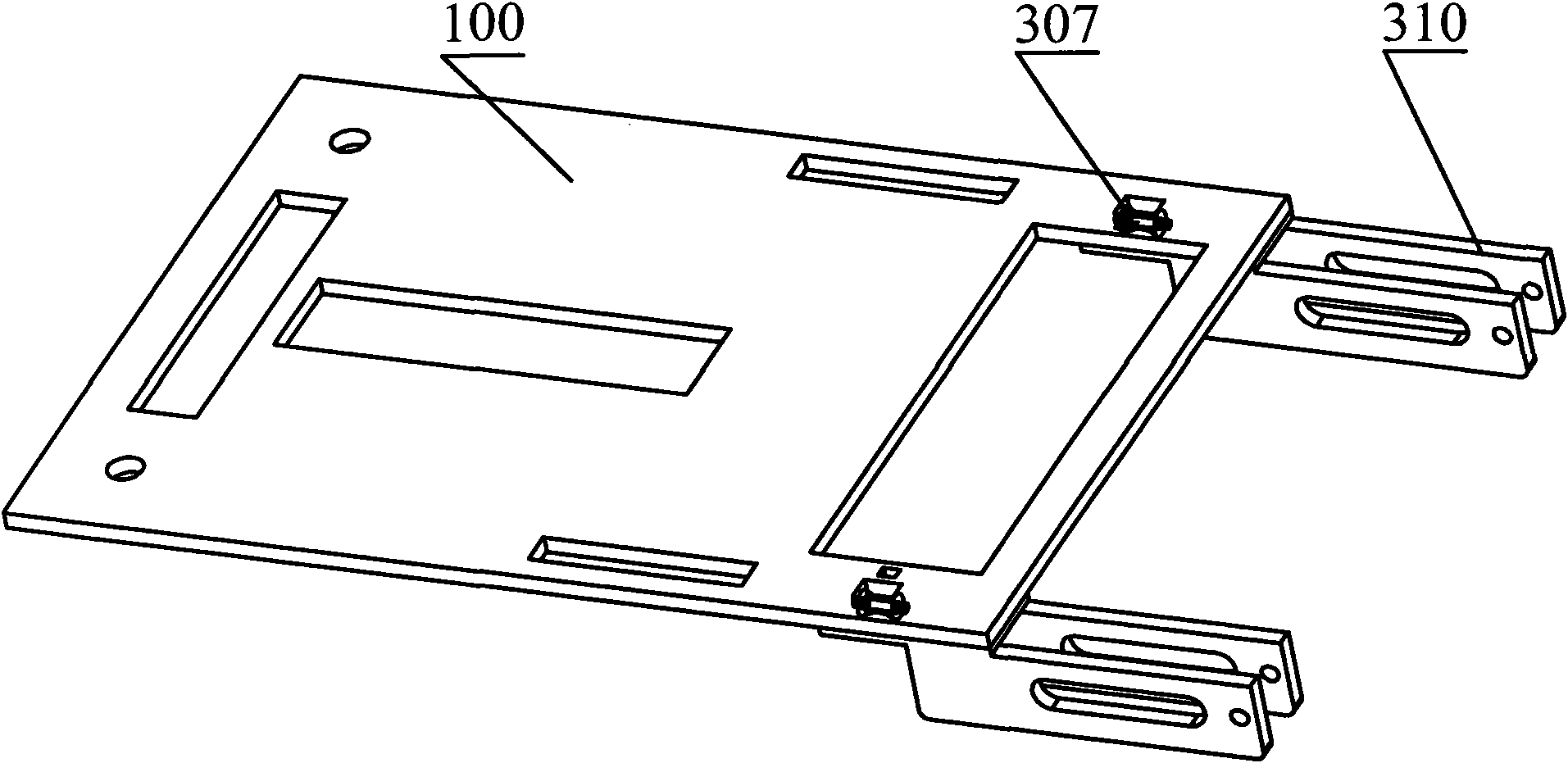

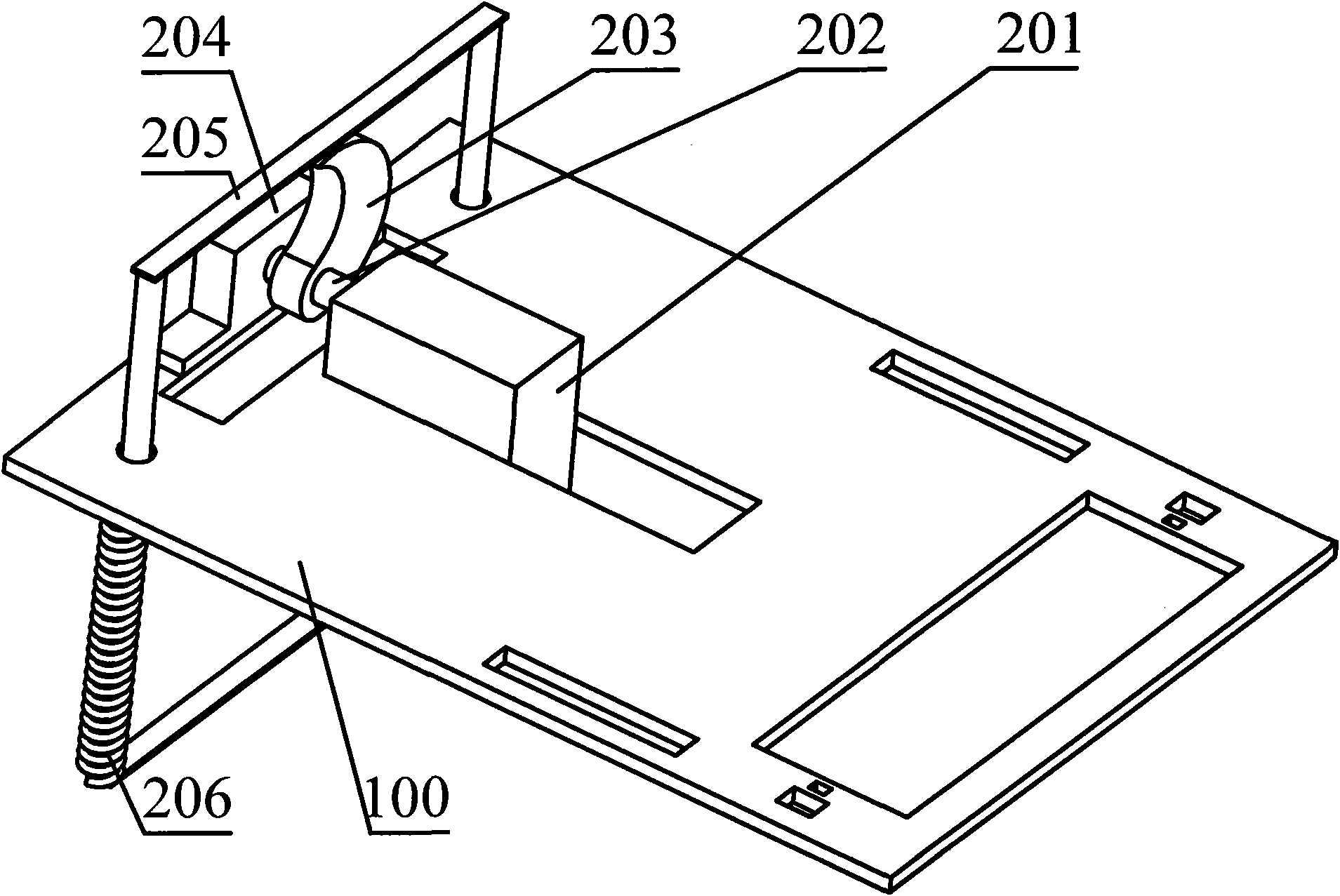

[0033] The present invention is installed with the front leg of drive and support and damping function in the front end of body 100, is installed in the rear end of body 100 with the rear leg of drive and movable joint lever elastic energy storage function. The body 100 is a cuboid structure as a whole, and holes and grooves are opened along the thickness direction on the body 100, such as figure 2 As shown, the front end of the body 100 is opened with a T-shaped through-slot, the middle of the rear end of the body 100 is opened with a rectangular through-slot perpendicular to the vertical side of the front-end T-shaped through-slot of the body 100, and two short sides of the rectangular through-slot are respectively opened. Rectangular slot, a smaller rectangular slot is opened near the short side of the rectangular through slot, and a larger rectangular slot is opened at the end away from the short side of the rectangular through slot. The length direction of the larger rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com