Method for preparing PbS spherical nano crystals by water-phase process

A nano-crystal and spherical technology, applied in the direction of lead sulfide, etc., can solve the problems of difficult control of orientation growth, few spherical nanostructures, unfavorable industrial application, etc., and achieve the effect of good crystal form, low cost and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

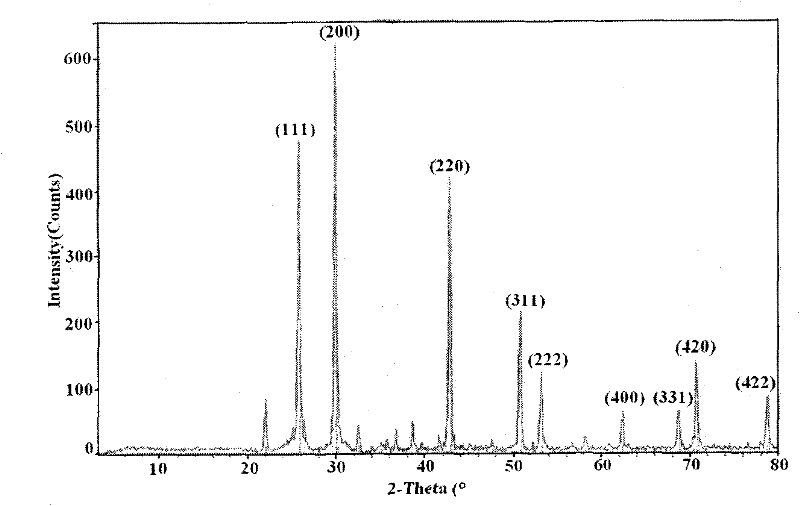

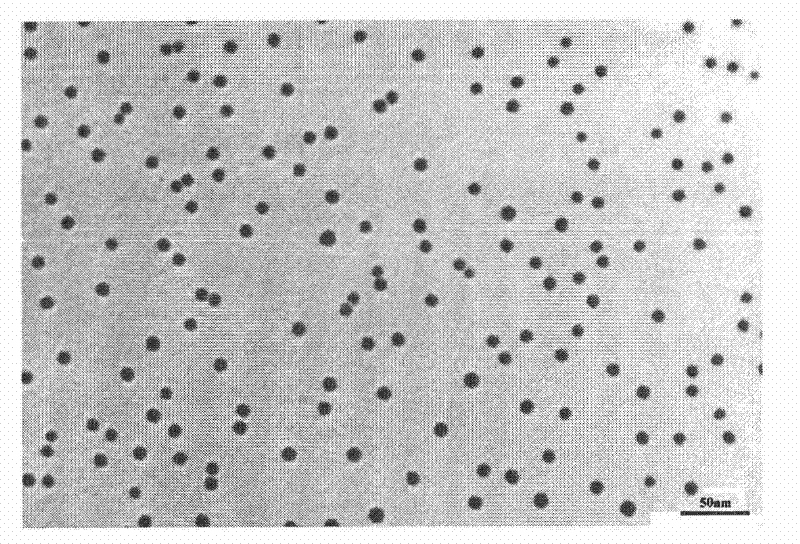

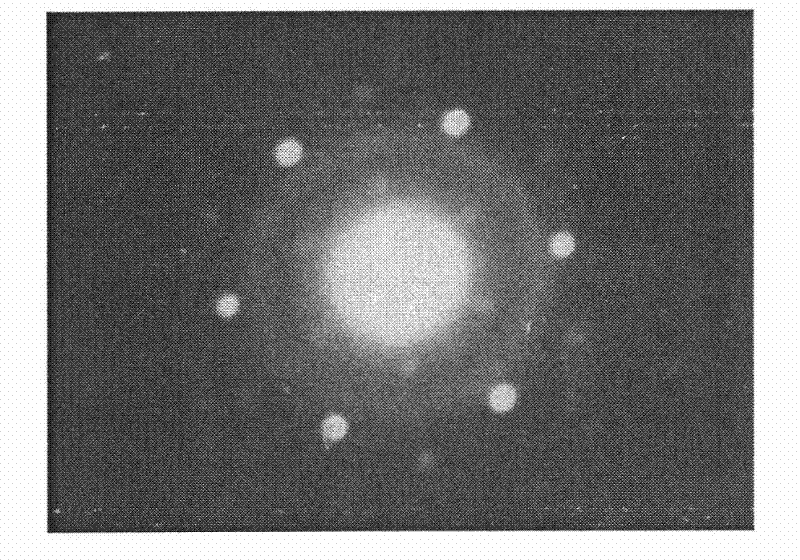

[0020] Add 8mL of distilled water, 4mL of 0.1M lead acetate solution, 7mL of 0.05M CTAB solution and 0.25mL (about 1.0mmol) of tert-dodecanethiol into a 100mL round-bottomed flask, mix the above solutions and place them in a constant temperature oil at 50°C. Stir evenly in the bath, then quickly inject 1mL of 0.1M sodium sulfide solution into the reactor, and reflux with tap water under stirring for 2 hours, 8 hours, 16 hours and 24 hours respectively. After the reaction, the centrifugation (12000rpm, 5min) was carried out after cooling to room temperature, the precipitate was washed successively with distilled water and absolute ethanol, and then the obtained precipitate was naturally dried at room temperature, and the obtained product was dark brown powder. By X-ray diffraction (XRD) (such as figure 1 shown) and electron diffraction pattern (as image 3 shown) shows that the product is a PbS nanocrystal; transmission electron microscopy (TEM) (such as figure 2 As shown), ...

Embodiment 2

[0022] Add 10mL of distilled water, 3mL of 0.1M lead acetate solution, 5mL of 0.05M CTAB solution and 0.25mL of tert-dodecanethiol (about 1.0mmol) into a 100mL round-bottomed flask, mix the above solutions and place them in a constant temperature oil at 100°C. Stir evenly in the bath, then quickly inject 2 mL of 0.1M sodium sulfide solution into the reactor, and reflux with tap water under stirring for 2 hours, 8 hours, 16 hours and 24 hours respectively. Then through the aftertreatment process of Example 1, the product form is obtained with Example 1. As the reflow time (2-24 hours) prolongs, the crystal form of PbS nanocrystals becomes better and the size increases.

Embodiment 3

[0024] Add 10mL of distilled water, 3mL of 0.1M lead acetate solution, 4mL of 0.05M CTAB solution and 0.25mL of tert-dodecylmercaptan (about 1.0mmol) into a 100mL round-bottomed flask, mix the above solutions and place them in a constant temperature oil at 100°C. Stir evenly in the bath, then quickly inject 3mL of 0.1M sodium sulfide solution into the reactor, and reflux with tap water under stirring for 2 hours, 8 hours, 16 hours and 24 hours respectively. Then through the aftertreatment process of Example 1, the product form is obtained with Example 1. As the reflow time (2-24 hours) prolongs, the crystal form of PbS nanocrystals becomes better and the size increases.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com