Processable Machinable complex-phase ceramic material and preparation method and secondary hardening heat treatment method thereof

A heat treatment method and technology of multiphase ceramics, applied in the field of ceramic material manufacturing, can solve the problems of limiting the application field of machinable ceramics, the inability to improve the hardness of machinable ceramics, the contradiction between machinability and hardness, and achieve hardness improvement, hardness and strength The effect of increasing and shortening the sintering time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

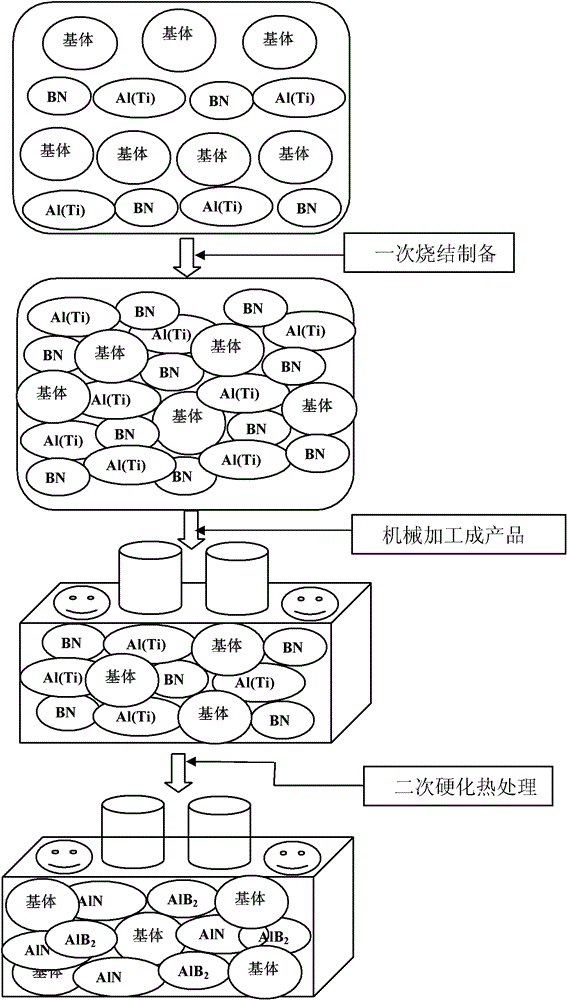

[0022] A method for preparing a machinable multiphase ceramic material, comprising the following steps: according to the above weight percentages, the ingredients are distributed, the mixed powder is ball milled, and then sintered in a plasma activation (PAS) furnace, wherein the heating rate is 300-500 ° C / min, and the pressure is 30- 50MPa, vacuum degree 6-10Pa, sintering temperature 900-1200℃, keep warm for 2-4min, and finally cool with the furnace.

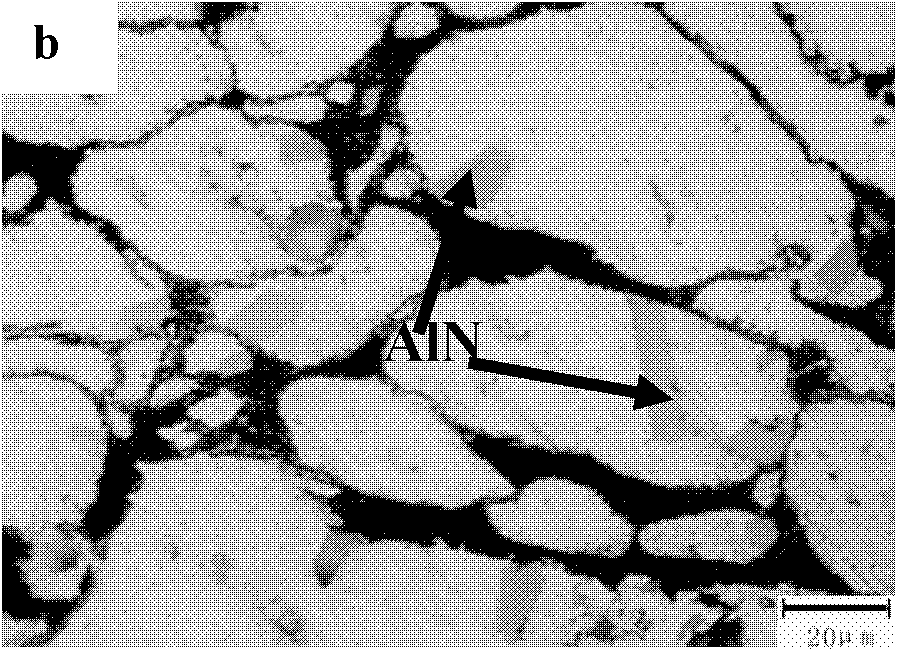

[0023] A secondary hardening heat treatment method for a machinable multiphase ceramic material. The machinable multiphase ceramic material prepared above is machined into a product, put into a vacuum furnace, and heated in N 2 Under gas protection, first raise to 900-1200°C at 5-10°C / min, then rise to 1600-1800°C at 2-5°C / min, keep warm for 2-3h, and finally cool with the furnace.

Embodiment 1

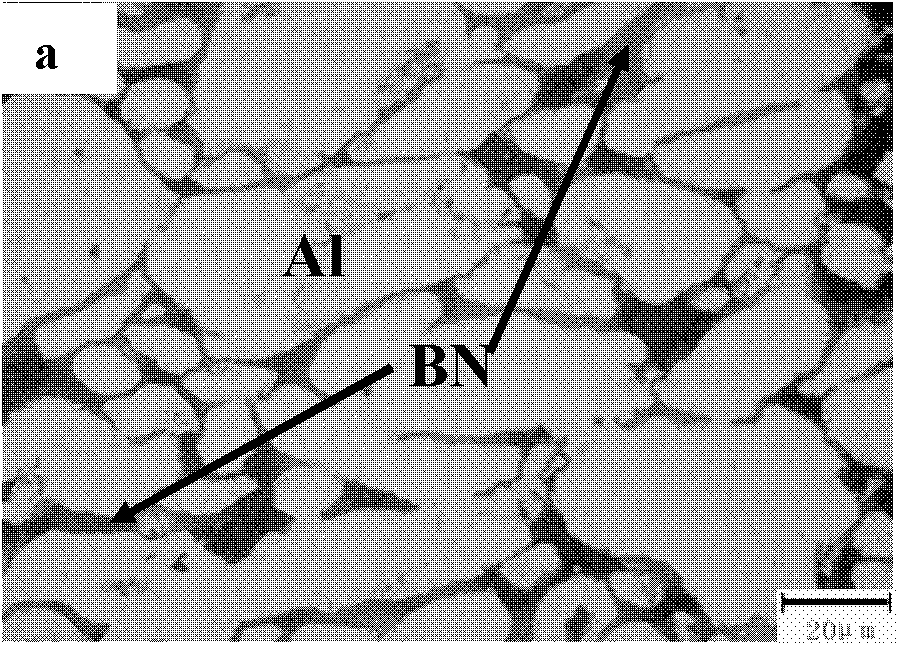

[0025] Machinable composite ceramic material ingredients: Al 2 o 3 It is the ceramic matrix phase, Al and h-BN are the toughening and reaction phases, and the weight percentage ratio of each component is Al 2 o 3 60%, h-BN15%, Al25%.

[0026] Preparation of machinable composite ceramic material: Mix the above-mentioned components, wet mill them in a ball mill jar for 24 hours, the medium is absolute ethanol (concentration 99.7%), the balls are agate balls, dry at 70°C, and pass through a 200-mesh sieve ; Then, the h-BN / Al / Al 2 o 3 The powder is loaded into a graphite mold and placed in a plasma activation furnace. Plasma activation (PAS) is rapidly sintered once. During the first sintering, the temperature is 1150°C, the heating rate is 300°C / min, the pressure is 30MPa, the vacuum degree is 10Pa, and the heat preservation is 2min. The sintering process Infrared temperature measurement is adopted, and it can be obtained after cooling with the furnace.

[0027] Secondary h...

Embodiment 2

[0030] Machinable composite ceramic material ingredients: Al 2 o 3 It is the ceramic matrix phase, Al and h-BN are the toughening and reaction phases, and the weight percentage ratio of each component is Al 2 o 3 75%, h-BN10%, Al15%.

[0031]Preparation of machinable composite ceramic material: Mix the above-mentioned components, wet mill them in a ball mill jar for 24 hours, the medium is absolute ethanol (concentration 99.7%), the balls are agate balls, dry at 70°C, and pass through a 200-mesh sieve ; Then put the h-BN / Al / SiC powder into the graphite mold, and put it into the plasma activation furnace, plasma activation (PAS) rapid primary sintering, the primary sintering temperature is 1200℃, the heating rate is 400℃ / min, and the pressure is 40MPa , Vacuum degree 8Pa, heat preservation 4min, infrared temperature measurement is used in the sintering process, and finally it is cooled with the furnace.

[0032] Secondary hardening heat treatment of machinable multiphase ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap