Rotary bin for vacuum continuous coating production line

A coating production line and vacuum technology, applied in the field of rotary silo, can solve the problems of multiple vacuum equipment, high cost, long production line, etc., and achieve the effect of reducing vacuum equipment, saving cost and shortening production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

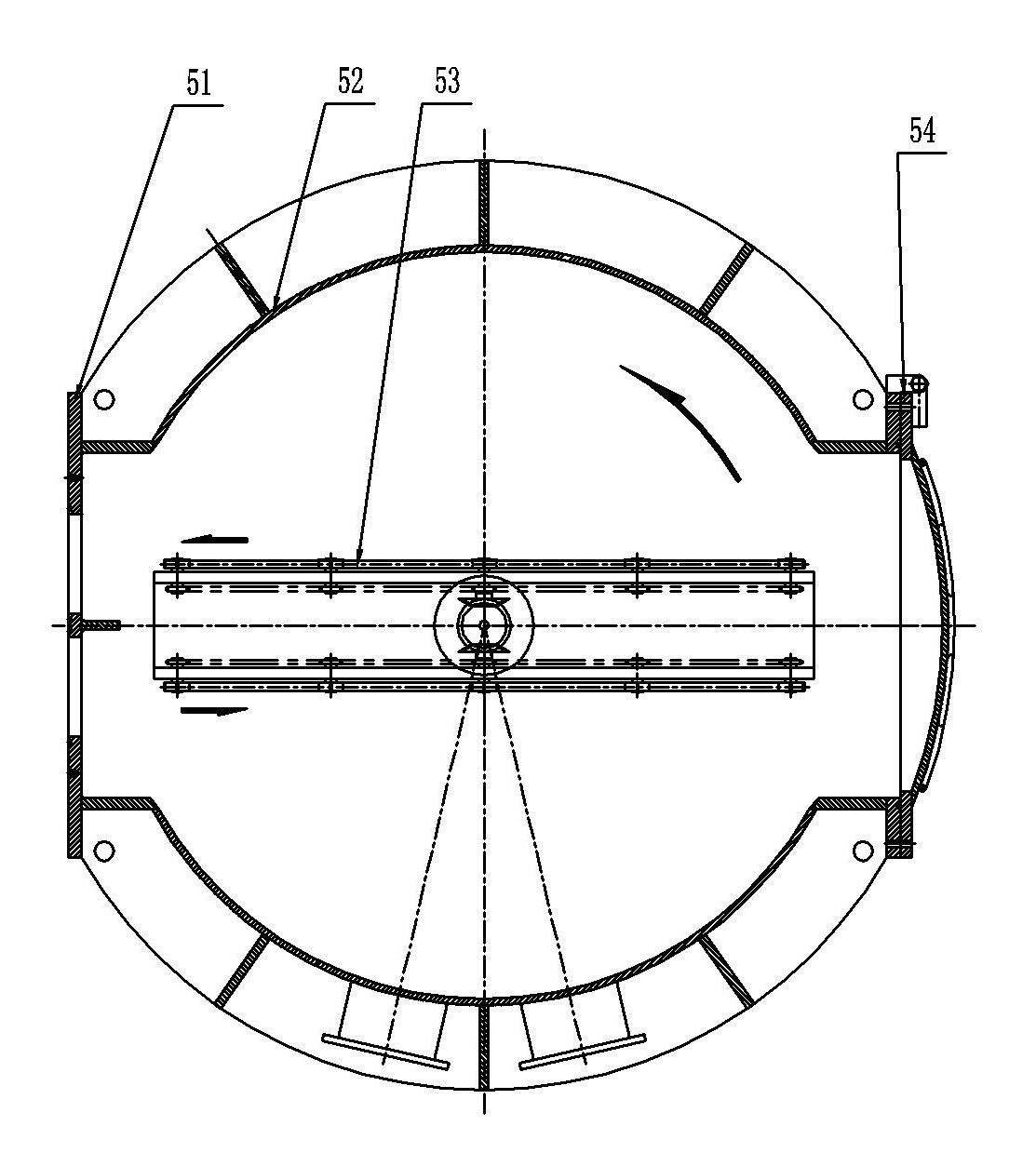

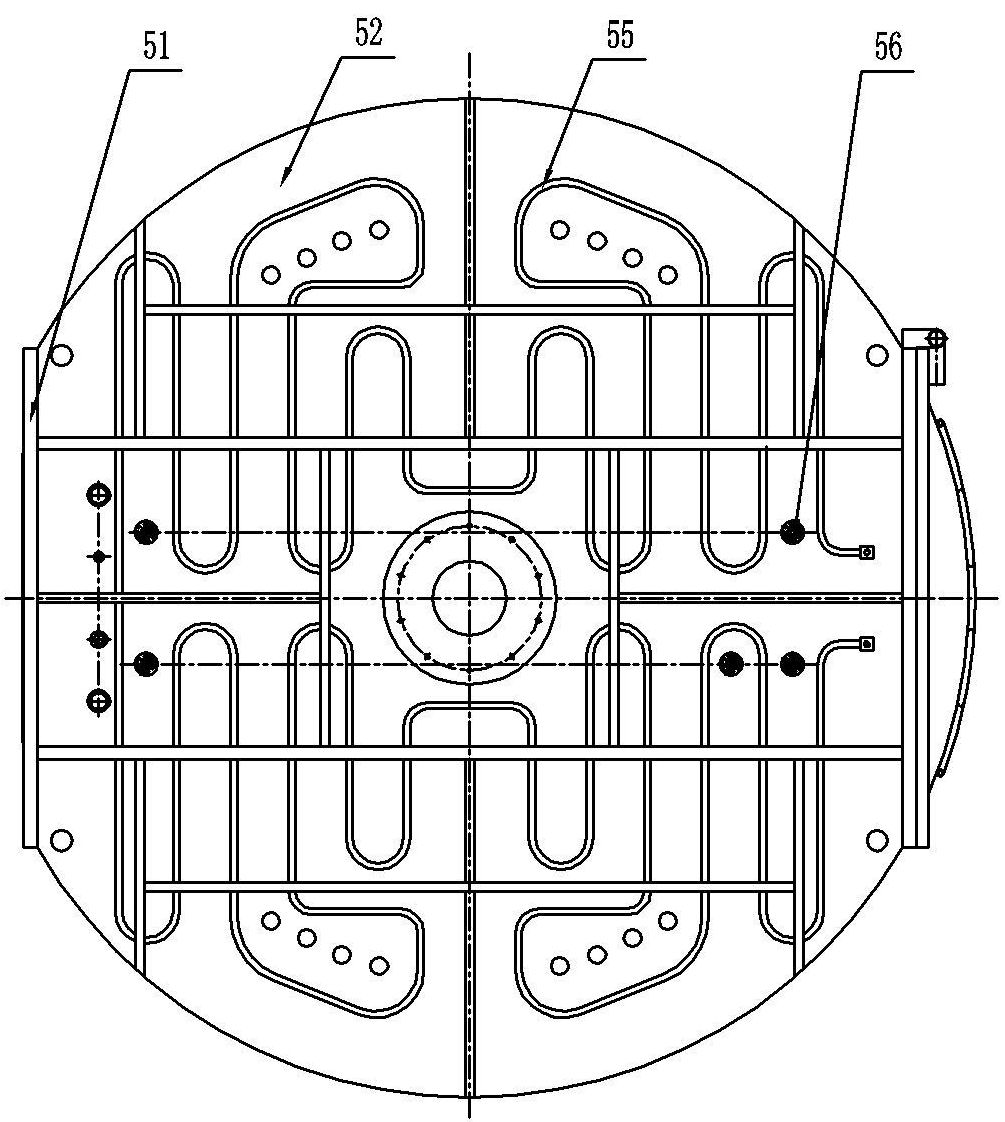

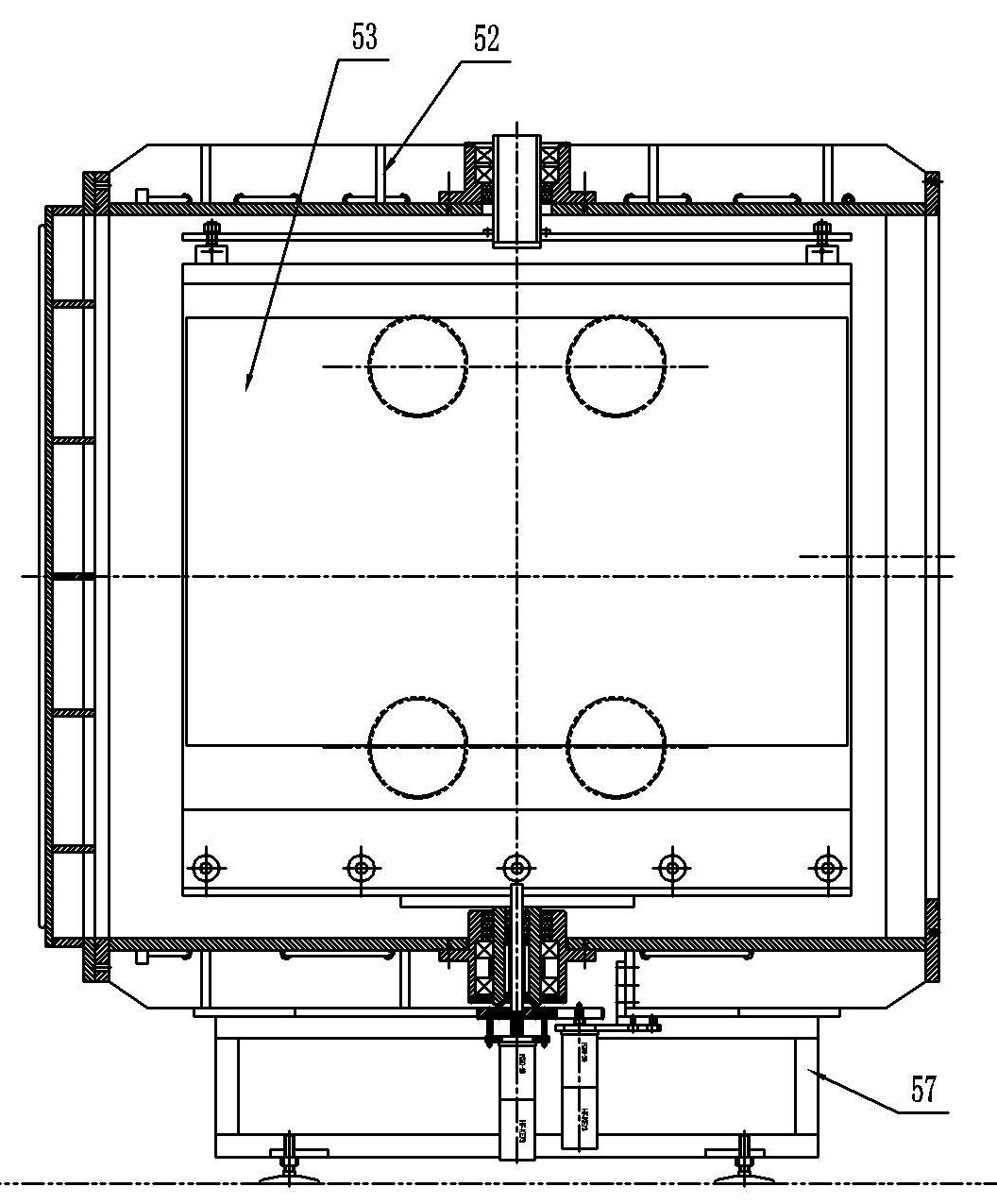

[0026] Embodiment 1, the present invention includes a bin body 52, a revolving bin door frame 51, a positioning device 56, and a rotary mechanism 53. The bin body 52 is fixedly mounted on a bin body frame 57, and a revolving bin door frame is arranged on one side of the bin body 52. 51. A rotary mechanism 53 compatible with the inner chamber of the container body 52 and a positioning device 56 matched with the rotary mechanism 53 are arranged in the bin body 52 . For the convenience of maintenance and observation, a sealed detection door 54 can also be arranged on one side of the bin body 52; One side of the warehouse body side wall water pipe 59 is provided, or the warehouse top water pipe 55 and the warehouse body side wall water pipe 59 are set at the same time; for the convenience of connection with the production equipment, the warehouse body connection door cover can also be installed on the outside of the rotary warehouse door frame 51 58, the connecting door cover 58 c...

Embodiment 2

[0033] Embodiment 2, for the convenience of heating the workpiece, the present invention can also install a heater 4 in the rotating frame 3 . refer to Figure 1 to Figure 9 , all the other are with embodiment 1.

Embodiment 3

[0034] Embodiment 3, the lower part of the lower rotating shaft 23 of the present invention can also be equipped with a pulley A, and the pulley A is connected with the pulley B of the rotary driving device, so as to realize rotation through a belt drive. Apparently, in the present invention, the lower part of the lower rotating shaft 23 can also be connected with the rotary cylinder, so as to realize the rotation through the transmission of the rotary cylinder. refer to Figure 1 to Figure 9 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com