Full-automatic assembling machine of bearing retainer

A bearing retainer, fully automatic technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of complex design, difficult assembly, multiple installation references, etc., and achieve high assembly quality, fast debugging, and beautiful appearance of the whole machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

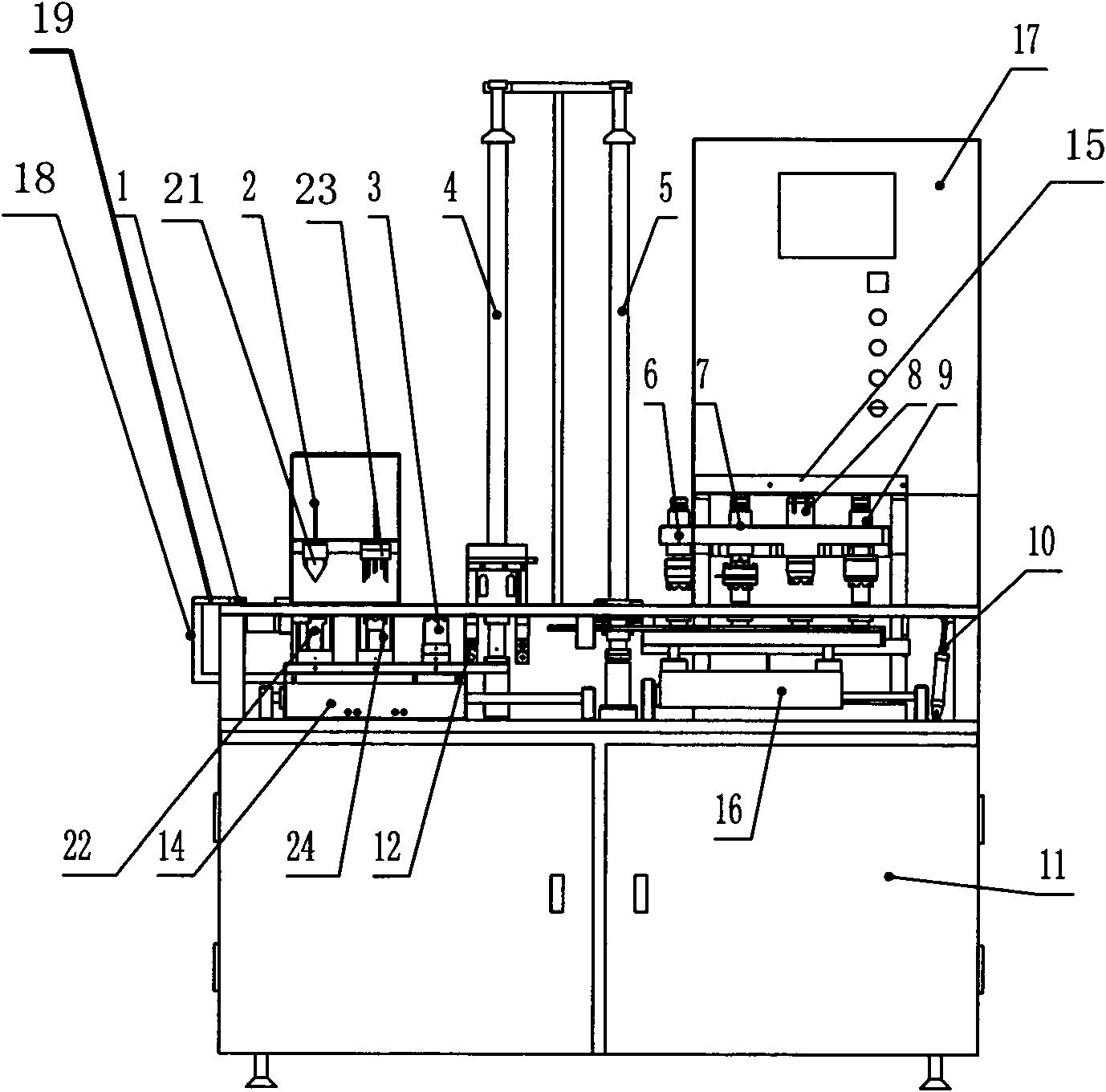

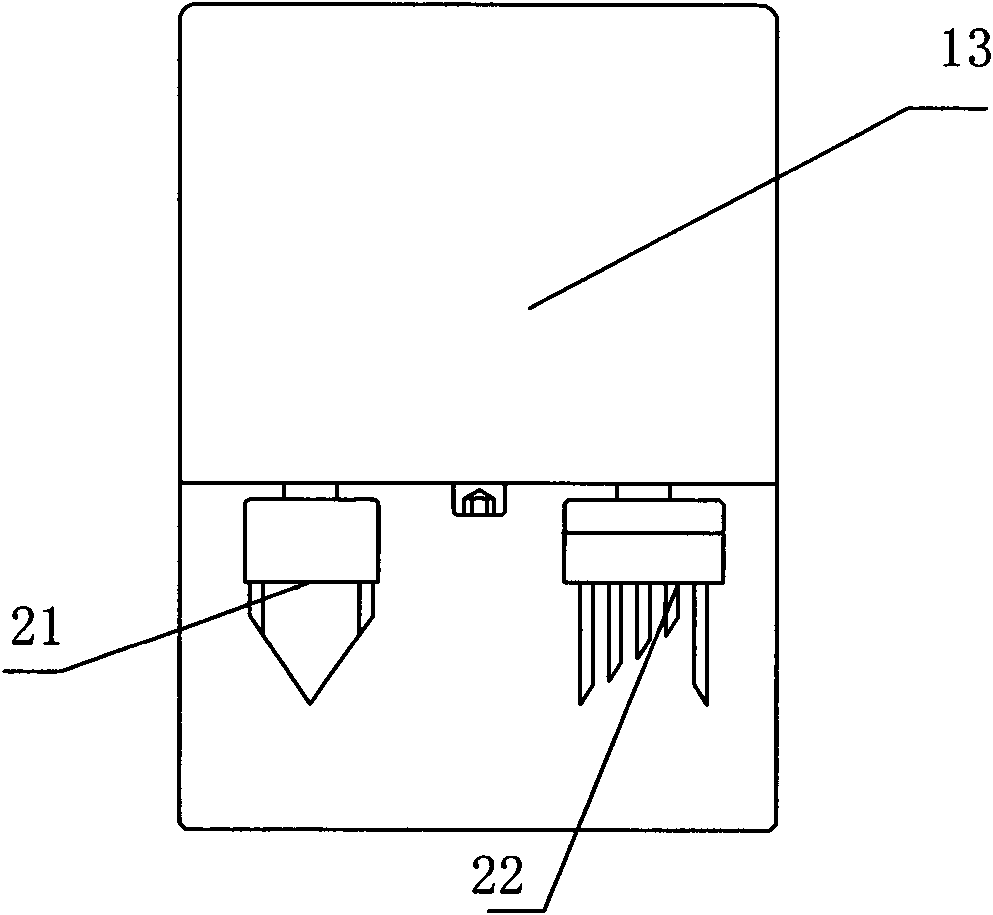

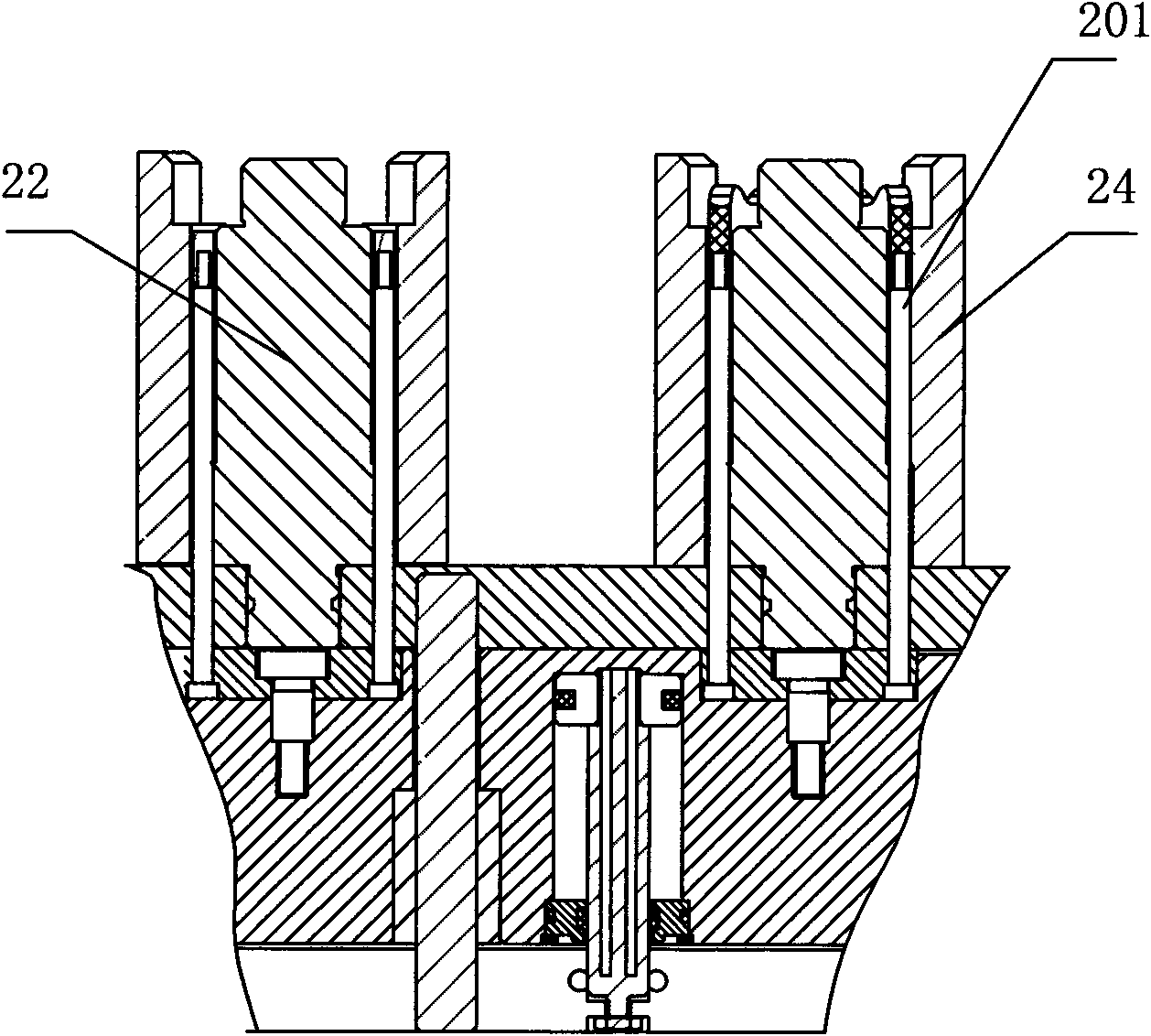

[0015] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 shown. Fully automatic bearing cage assembly machine, including feeding device 1, steel ball separating device 2, ball inspection device 3, upper cage blanking device 4, lower cage feeding device 5, nailing mold device 6, nail inspection mold device 7. Rivet riveting device 8, detection device 9 after riveting, finished product conveying device 10, semi-finished product kicking waste device 11 and frame 12, the feeding device is located on the left side of frame 12, and the described steel ball gathering and separating device 2 includes Ball gathering upper mold 21, ball gathering lower mold 22, and corresponding ball dividing upper mold 23, ball dividing lower mold 24, ball gathering upper mold 21 and ball dividing upper mold 23 are sequentially installed on the steel ball gathering and dividing bracket 13 , and be connected with the cylinder in the steel ball bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com