Vacuum transmission pipe and connecting structure thereof

A vacuum transmission and vacuuming technology, which is applied in the direction of flange connection, sealing surface connection, pipe/pipe joint/pipe fitting, etc., can solve the problems of thick heat transfer pipe and unsatisfactory heat transfer effect, and achieve good and good heat preservation effect Thermal insulation effect, effect of preventing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

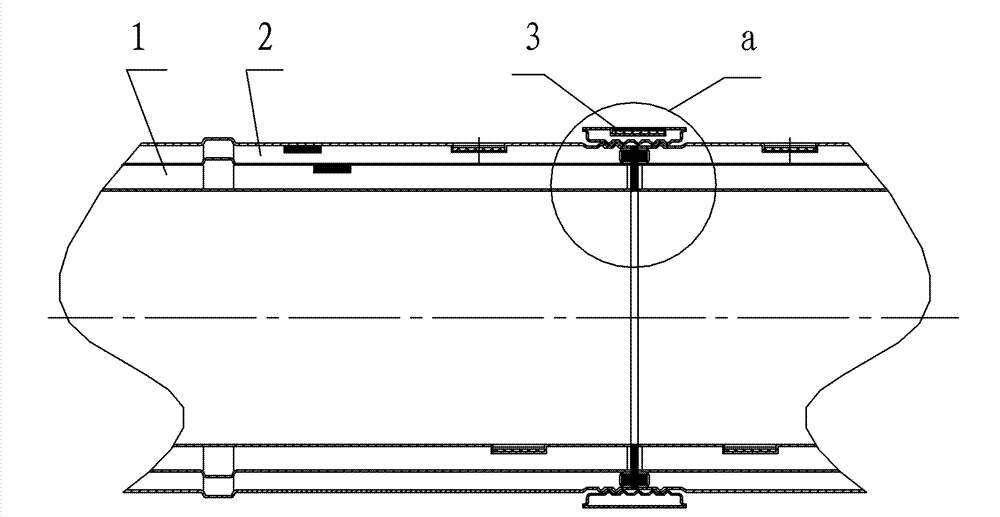

Embodiment 1

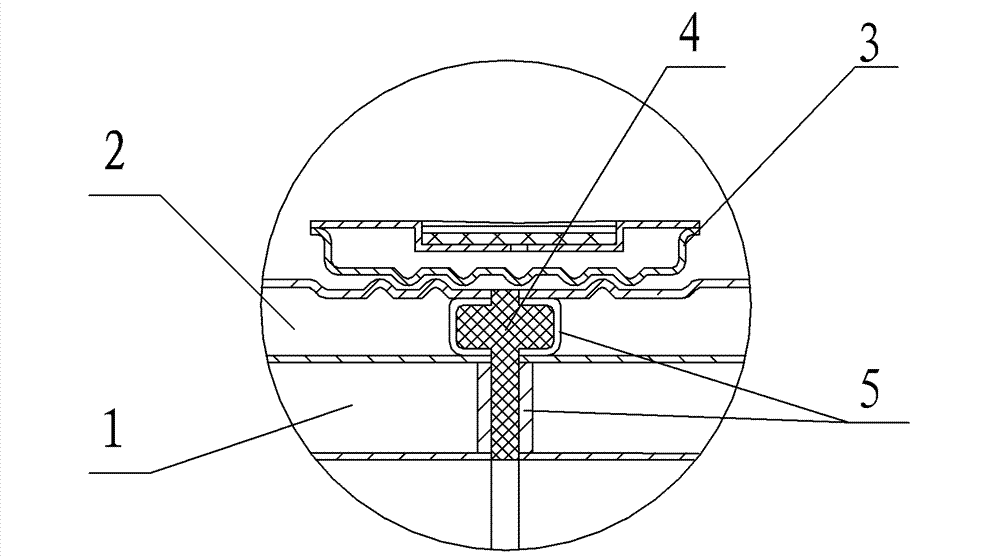

[0020] Embodiment 1: This embodiment is a double-layer vacuum heat insulation pipe composed of three layers of pipes. The inner layer vacuum heat insulation pipe 1 is vacuumized between the inner layer pipe and the middle layer pipe, and the vacuum heat insulation pipe 1 is between the outer layer pipe and the middle layer pipe. Vacuum outer layer vacuum heat insulation pipe 2, two adjacent vacuum transmission pipes are connected by a connecting piece in the axial direction, the connecting piece is composed of a collar 3 and a sealing piece 4, and the collar 3 is vacuum insulation The inner surface of the pipe is provided with threads, the outer surface of the end of the vacuum transmission pipe is provided with threads, and the threads on the inner surface of the coupling are respectively connected with the threads on the outer surfaces of the ends of two adjacent vacuum transmission pipes.

[0021] In the inner and outer vacuum heat insulation pipes, the ends of each layer of...

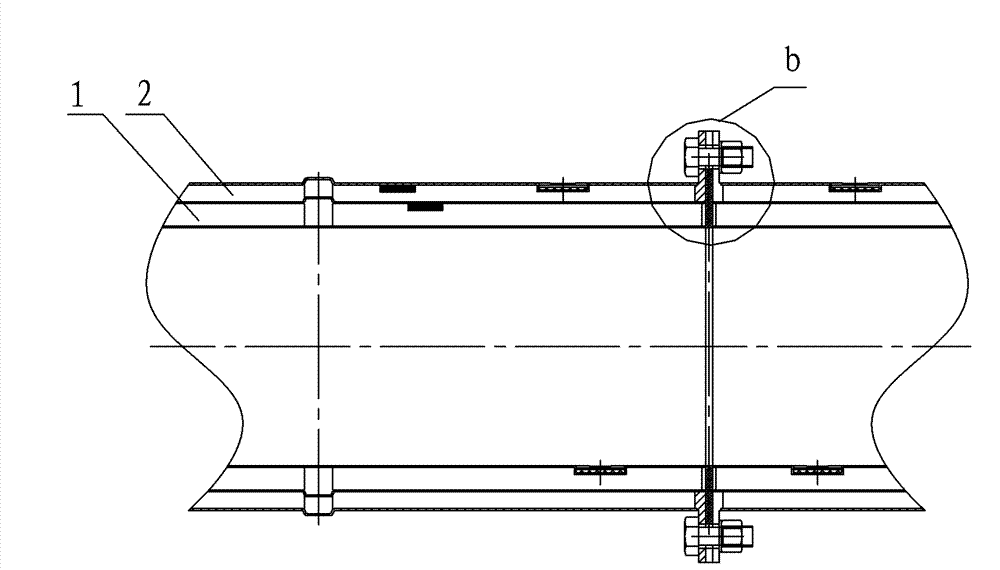

Embodiment 2

[0023] Embodiment 2: This embodiment is basically the same as Embodiment 1, except that the connecting piece is composed of a flange 6 , a seal 4 and a connecting bolt 7 . Sealed plugs 5 are welded to the ends of the inner and outer vacuum heat insulation pipes in the vacuum transmission pipe, and the plugs 5 are sealed and welded to the end faces of the inner and outer pipes of each layer of vacuum heat insulation pipes. The flange 6 is integrated with the plug 5 at the end of the outer vacuum heat insulation pipe 2, the outer end surface of the plug 5 at the end of the inner vacuum heat insulation pipe 1 is a plane, and the end surface of the flange is insulated from the inner vacuum heat insulation The outer end faces of the plug 5 at the end of the pipe 1 are on the same plane. Two adjacent vacuum transmission pipes are connected by flanges 6 through connecting bolts 7, and the seal 4 used between the flanges and the two adjacent vacuum transmission pipes is a gasket.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com