Ice maker

A throttling device and ice cylinder technology, which is applied in ice making, ice making, lighting and heating equipment, etc. It can solve the problems of refrigerant leakage, users cannot know the refrigerant supply, and difficult to seal, so as to solve the leakage problem Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

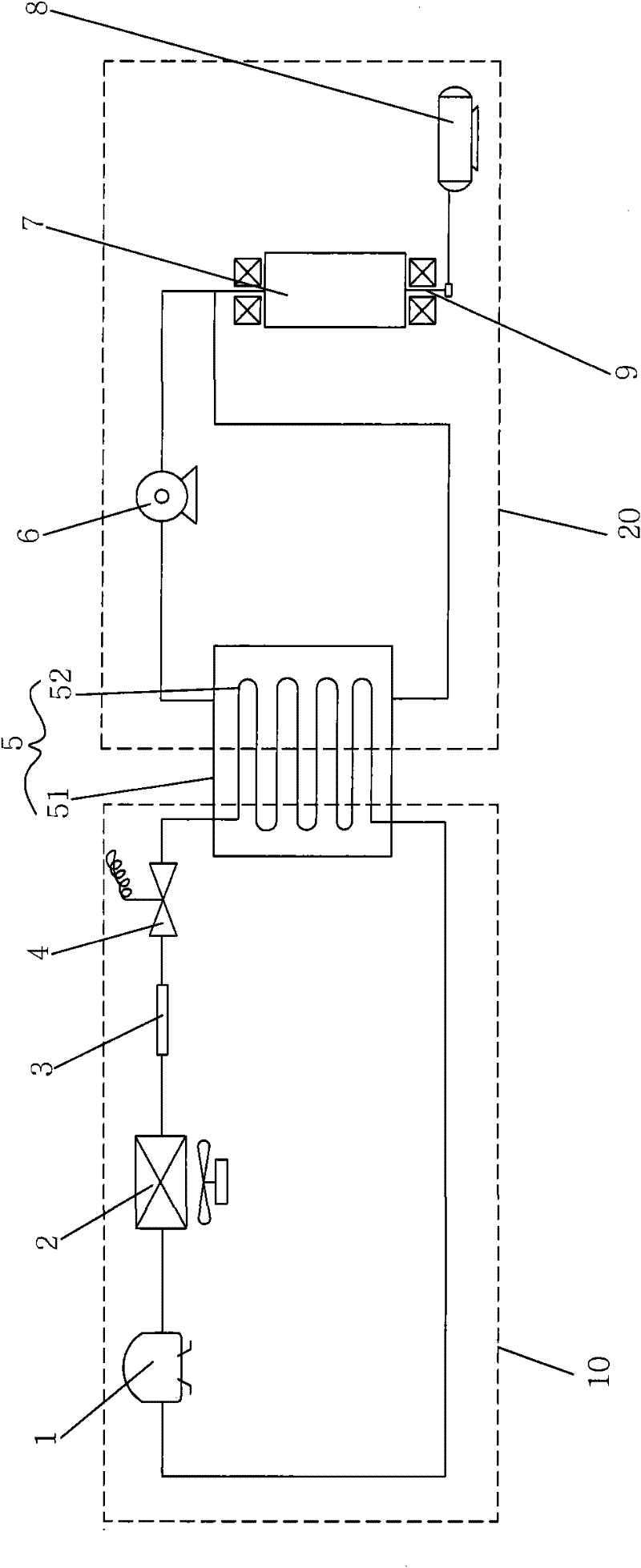

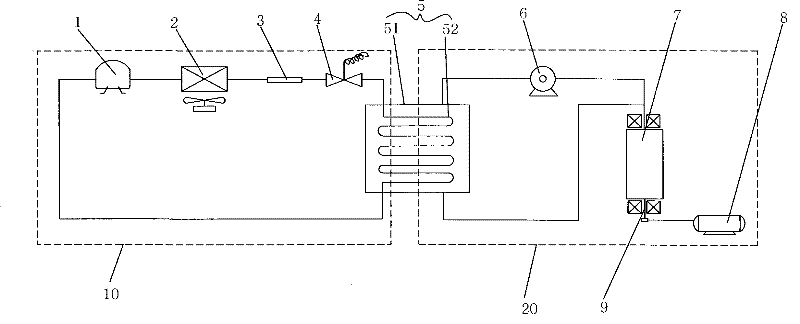

[0023] figure 1 Represented is a schematic diagram of an embodiment comprising the technical solution of the present invention:

[0024] As shown in the figure, the ice making device includes two circulation systems, and the one on the left is a common refrigerant circuit system 10, which includes a compressor 1, an air-cooled condenser 2, a dry filter 3, and a throttling device 4. Heat exchanger 5. The heat exchanger 5 includes an outer shell 51 and an evaporation coil 52 inside the outer shell 51 . The compressor 1 , the air-cooled condenser 2 , the dry filter 3 , the throttling device 4 and the heat exchanger 5 have an interconnection structure forming a refrigerant circuit system 10 . Specifically: the air outlet of the compressor 1 is connected with the outlet of the condensing pipe of the air-cooled condenser 2, the outlet of the condensing pipe of the condenser 2 is connected with the inlet of the drier filter 3, and the inlet of the drier filter 3 is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com