Method for detecting and monitoring high-resistance ground fault by online zero setting and test device thereof

A technology for monitoring high-resistance and ground faults. It is applied in the direction of measuring devices, fault locations, and measuring electricity. It can solve problems such as the inability to overcome the influence of distributed capacitance, and achieve the effects of eliminating DC signal drift, truly receiving signals, and eliminating distributed capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

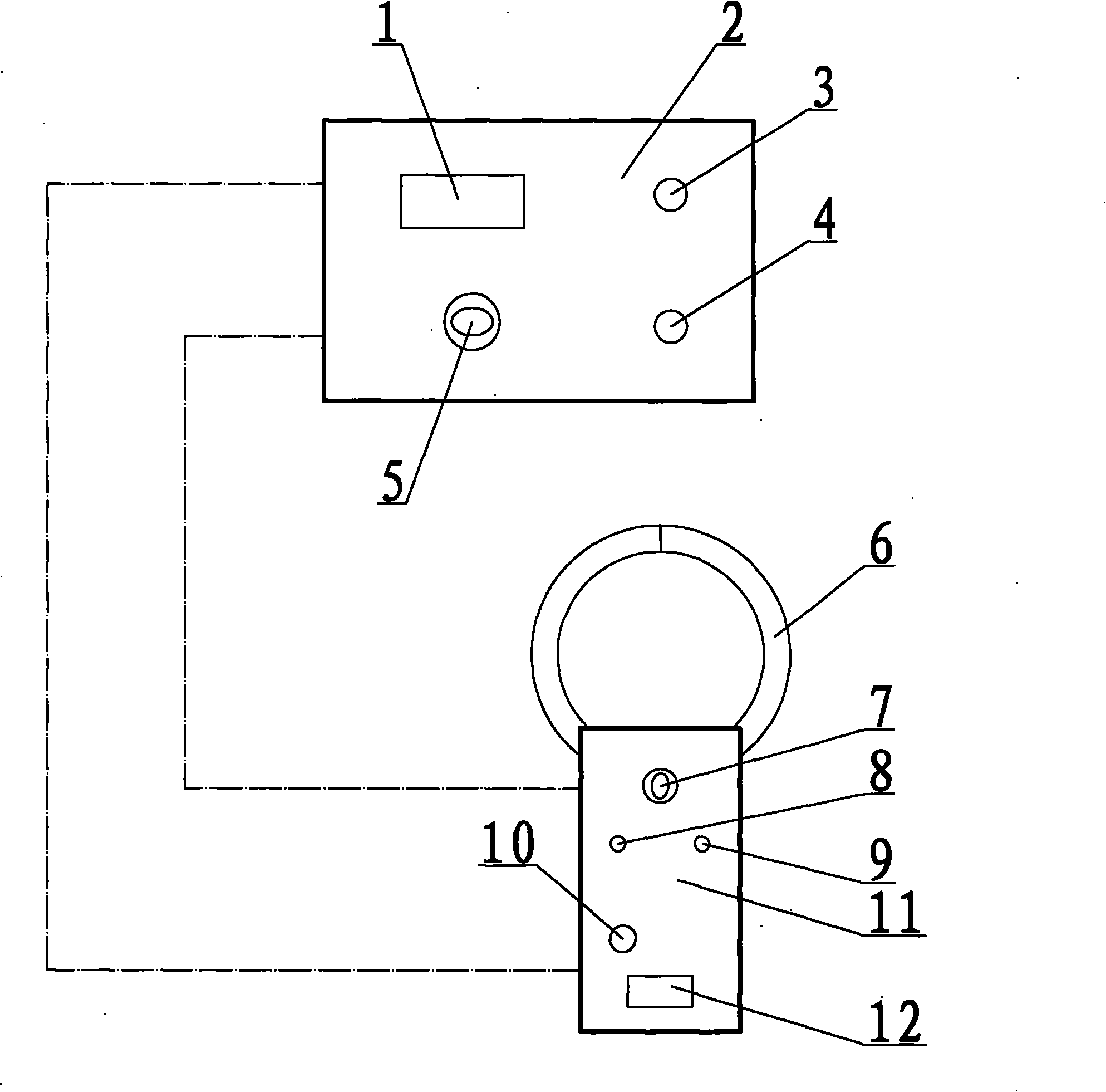

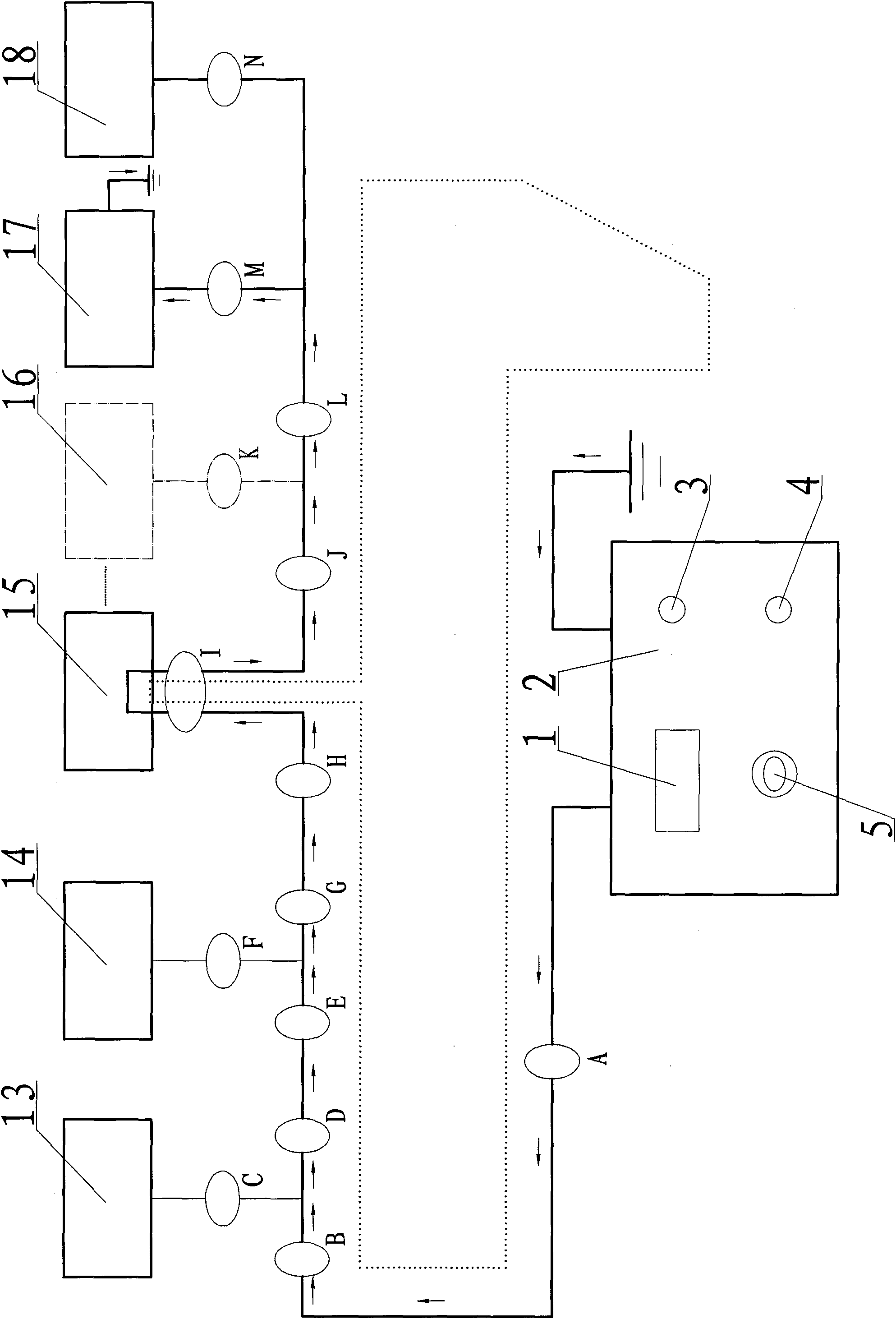

[0018] A method for online zero-setting detection and monitoring of high-resistance grounding faults, such as Figure 1 to Figure 6 As shown, it includes a DC waveform signal generator and a DC current signal receiver that can generate a DC tooth wave signal. The claws of the clamp transformers of all the above-mentioned DC current signal receivers are sequentially stuck on the faulty line connected to the electrical equipment. Constitute one or more stuck line points;

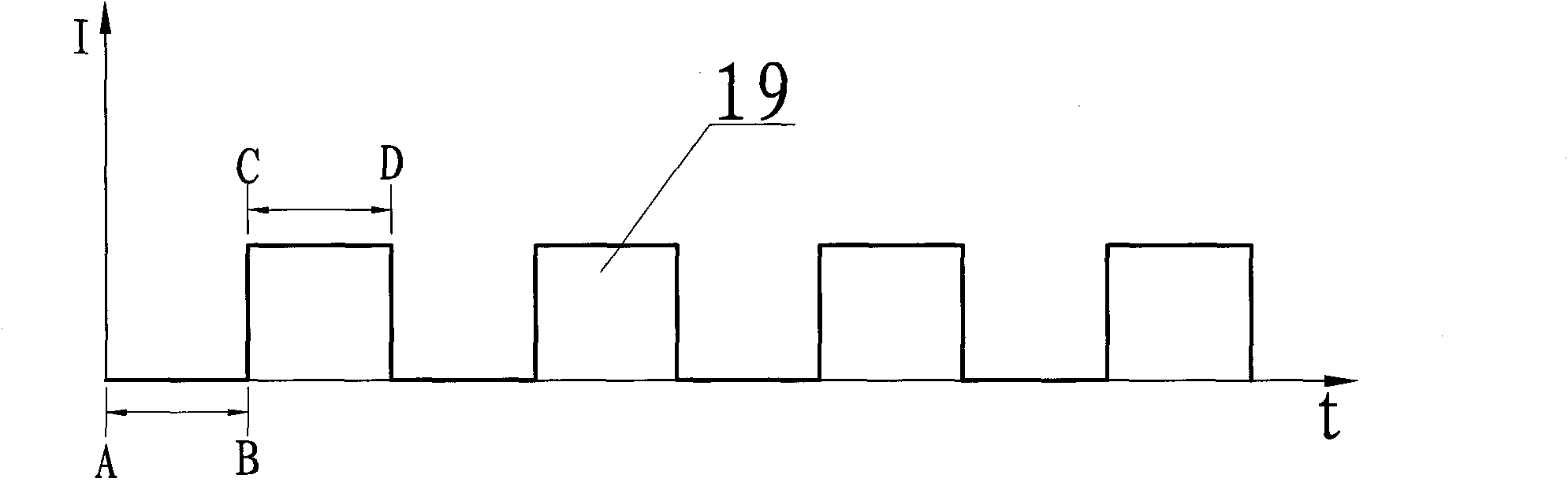

[0019] (I) Connect one of the two signal output terminals of the DC waveform signal generator to one end of the faulty line, and the other terminal to the ground or to the other end of the faulty line, and use the DC waveform signal generator to apply a voltage to the faulty line. The DC tooth wave signal makes the applied DC tooth wave signal pass through the fault line to form a closed circuit of the DC tooth wave current, and in turn the DC current signal receiver receives the DC tooth wave through its claw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com