Rolling hexagonal cold-drawing cover die

A rolling die and cold drawing technology, applied in the direction of wire drawing dies, etc., can solve the problems of high price, time and energy waste of cemented carbide cold drawing dies, and achieve the effect of shortening the production cycle, reducing the use of acid, and less investment in molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

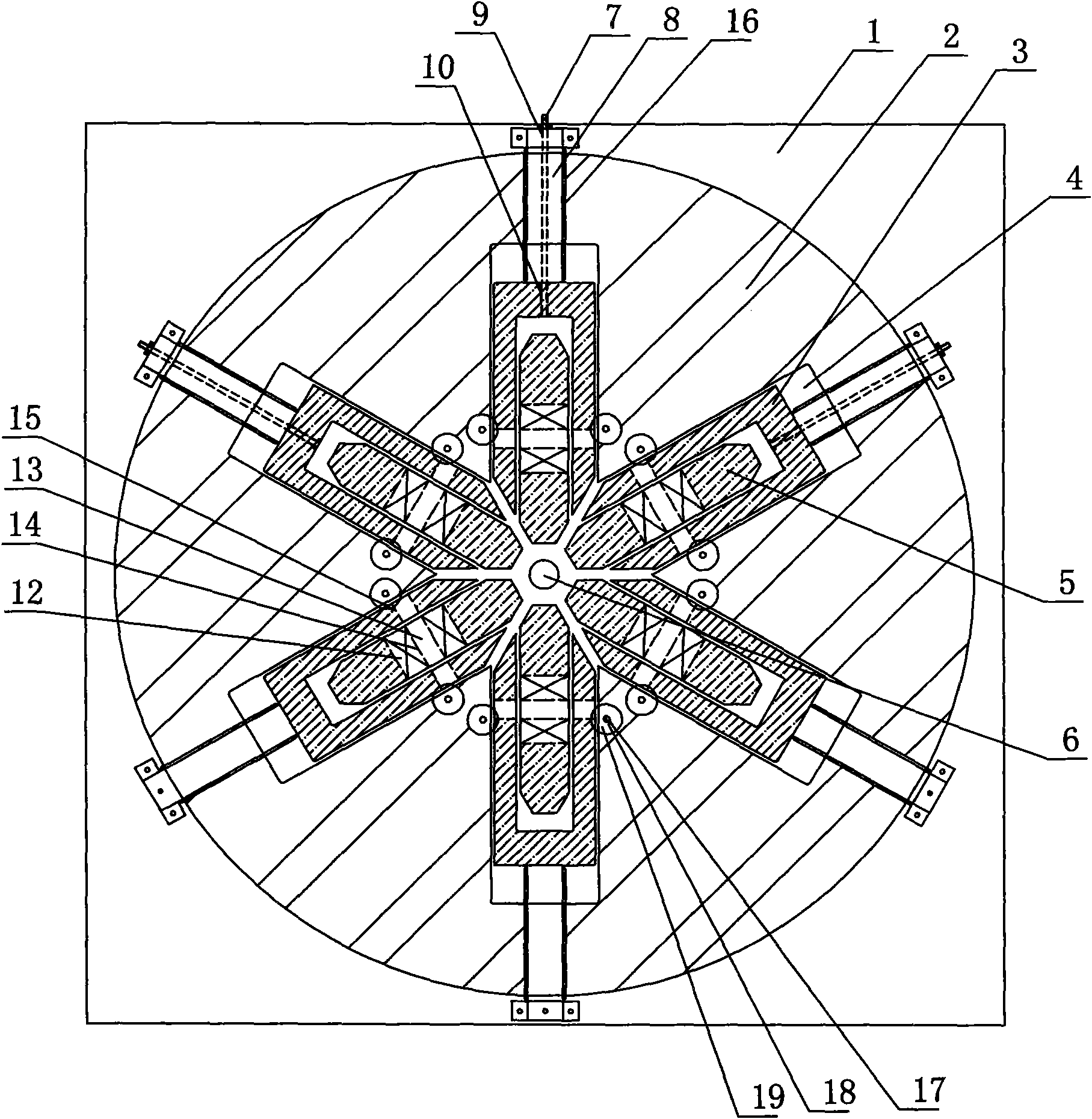

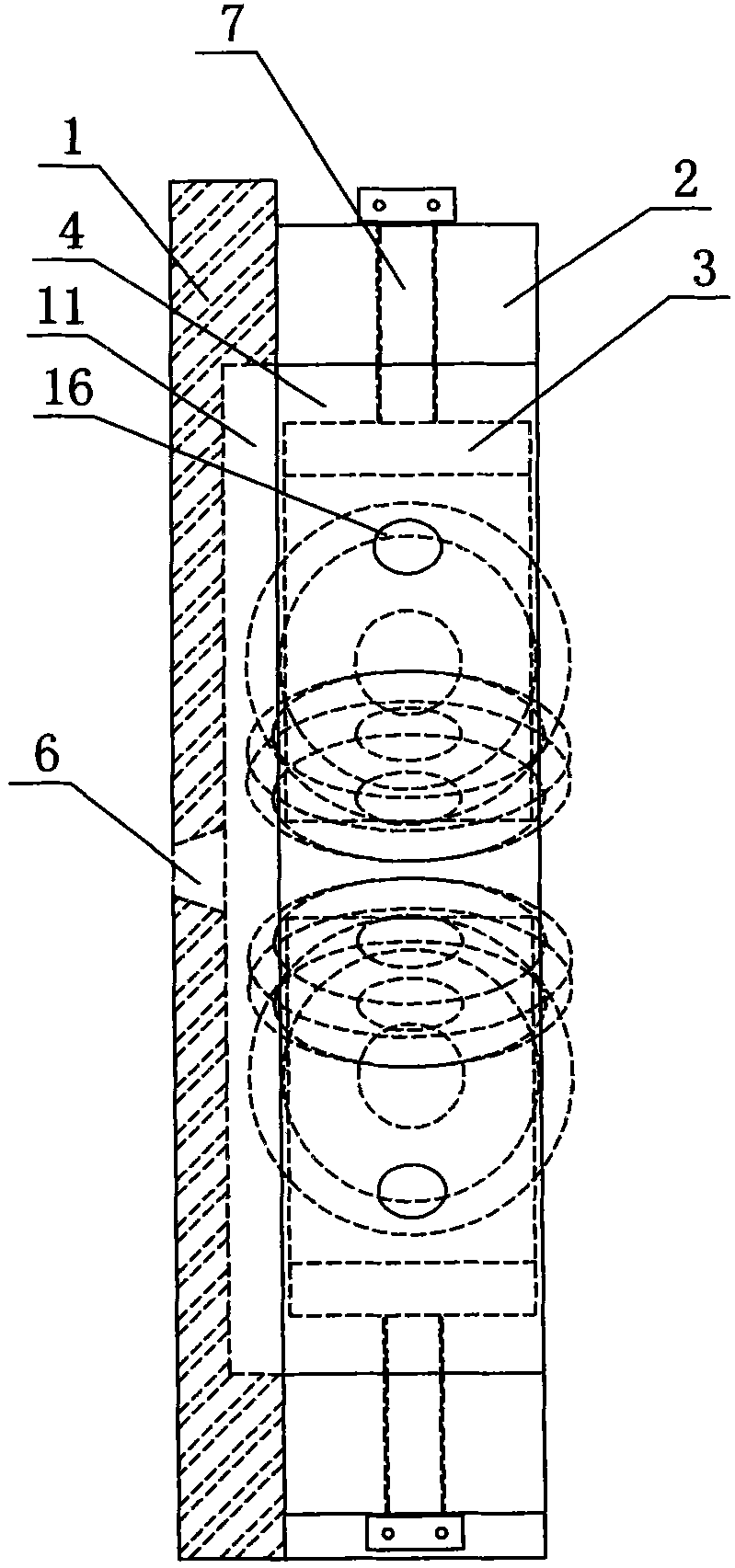

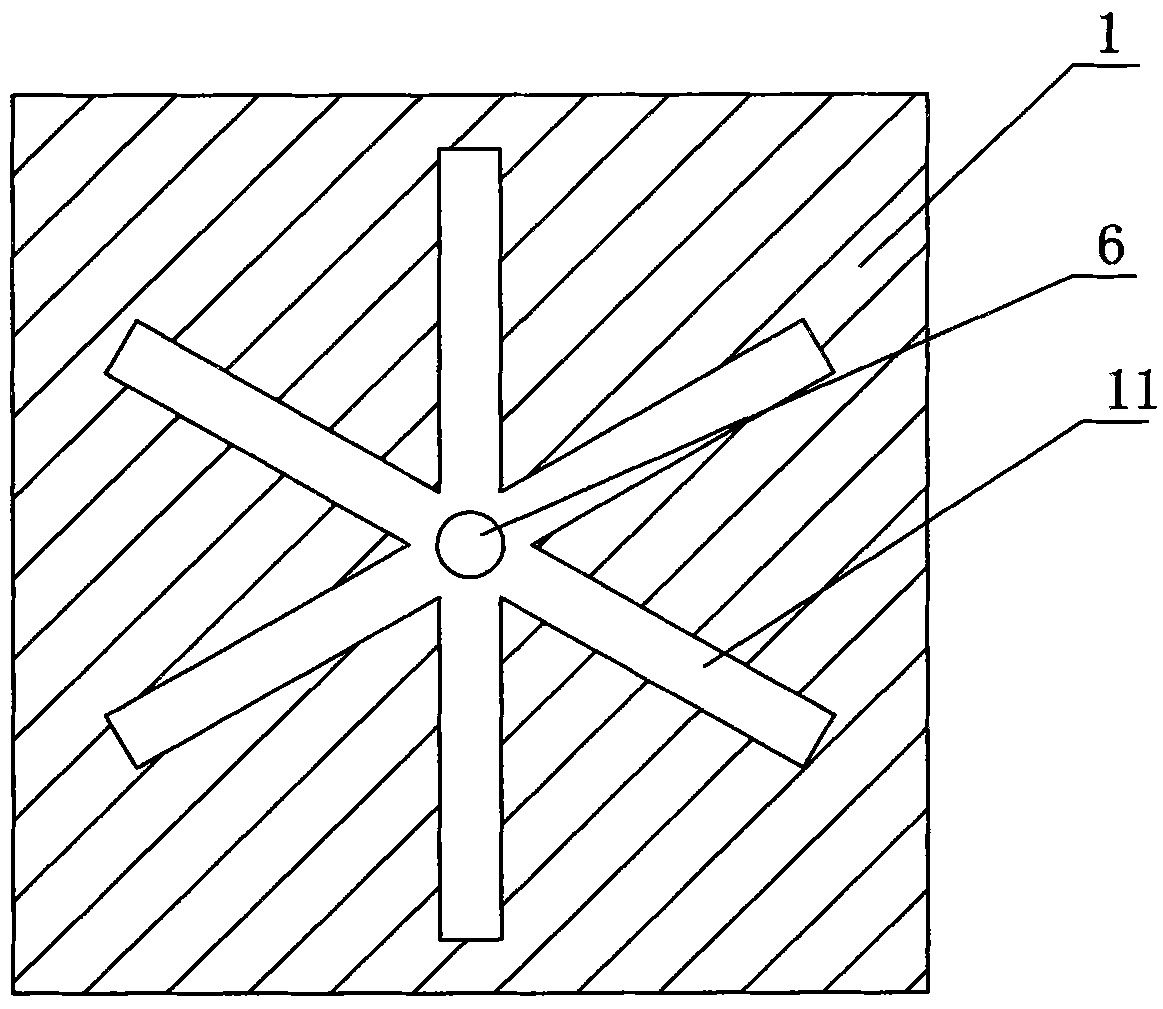

[0024] Such as figure 1 , 2 , 3, and 4, the rolling hexagonal cold-drawing die includes a mold base plate 1, a feeding hole 6 and six rolling grooves 11 are set on the mold base plate 1, and the six rolling grooves 11 are evenly distributed on the sides of the feeding hole 6 peripheral. The mold body 2 is fixed on the mold bottom plate 1, and six mold rolling seat grooves 4 are evenly distributed on the mold body 2 along the circumferential direction, and each rolling mold seat groove 4 is respectively arranged above the corresponding rolling mold groove 11.

[0025] Rectangular rolling die seats 3 with one end open are respectively arranged in each die rolling seat groove 4 , and the opening direction of each die rolling seat 3 faces the feeding hole 6 respectively. Each rolling die seat 3 is composed of two transverse sections 3-1 and a longitudinal section 3-2 respectively, the two ends of the longitudinal section 3-2 are respectively fixed to the transverse section 3-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com