Manufacture method for integral splayed sand blocking net

A technology of a figure-eight sand blocking net and a manufacturing method, which can be applied to nets, other household appliances, household appliances, etc., can solve problems such as time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

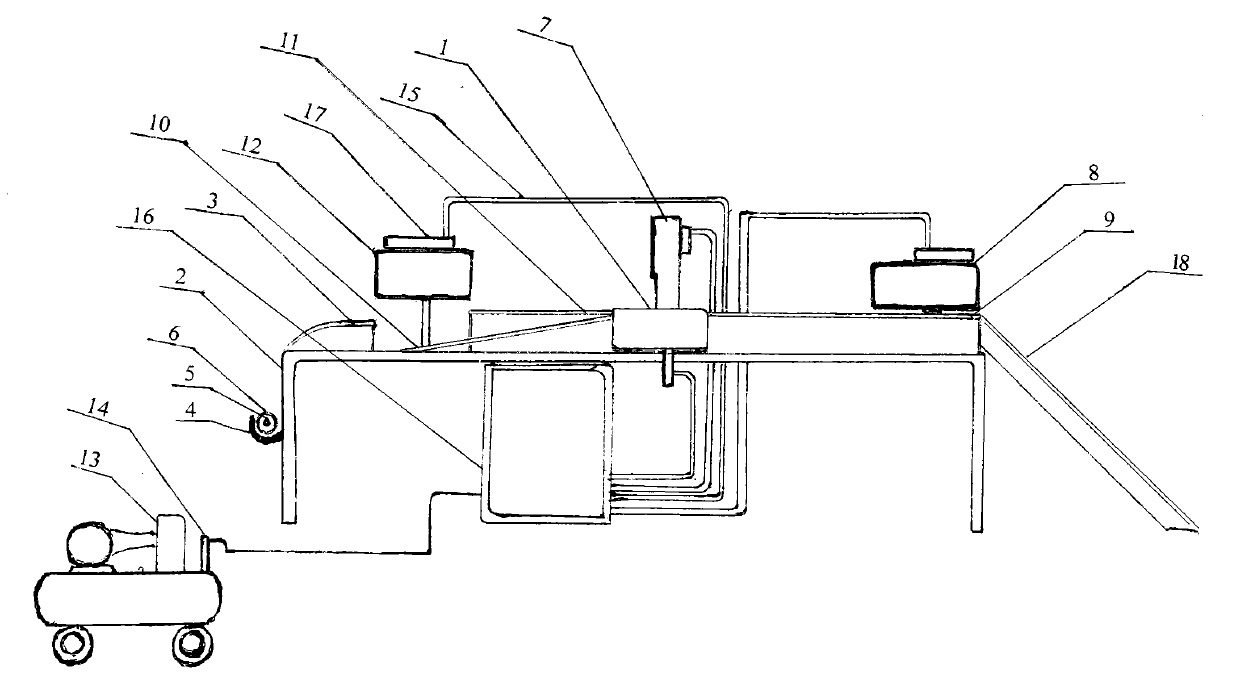

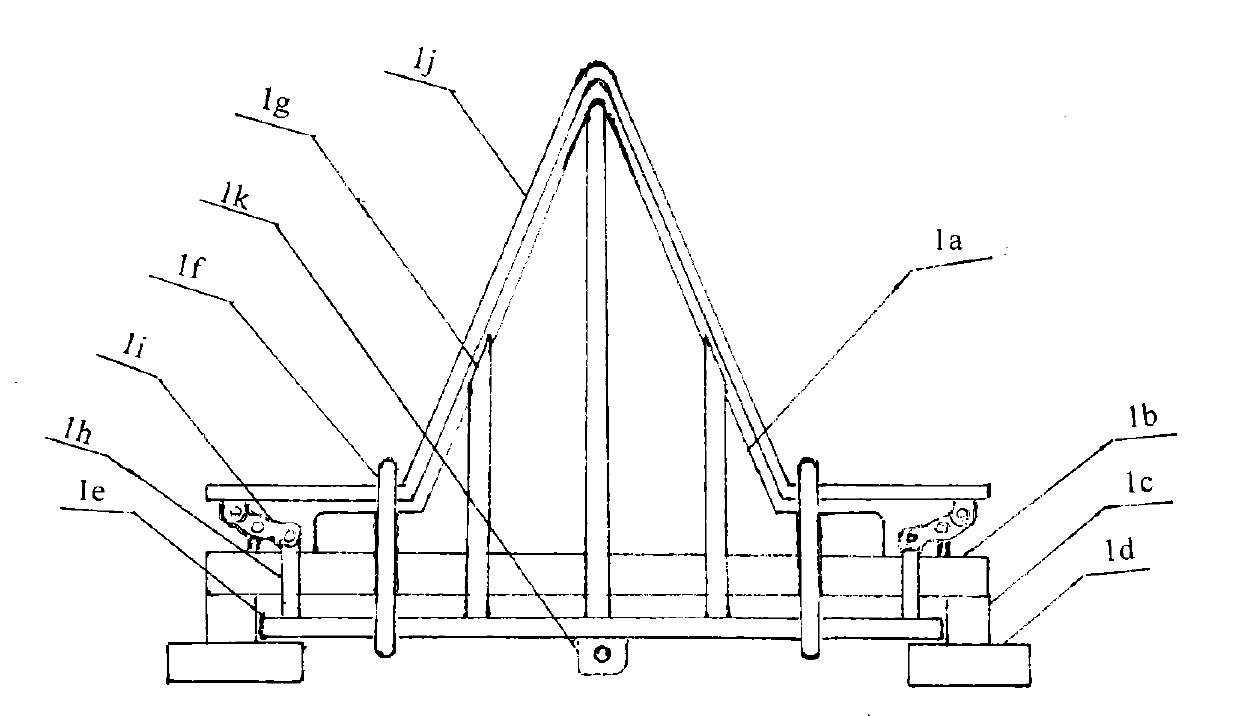

[0012] now attached figure 1 , 2 , 3, 4, 5 further describe the manufacturing method of the integrated figure-eight sand-blocking net of the present invention as follows: the manufacturing method of the integrated figure-eight sand-blocking net is to be assembled (production) by the plastic net and the figure-eight-shaped net clamp with the assembly machine .

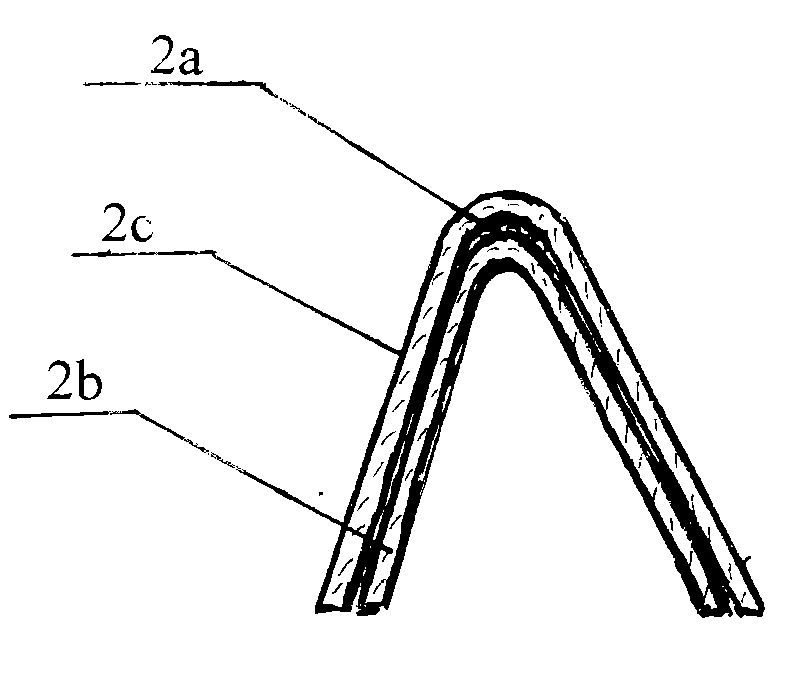

[0013] The plastic net (2a) is made of anti-oxidant and reinforced plastics. The weaving specification of the plastic net is 1.5 mm × 0.2 mm for weft wire (flat shape), φ0.3 mm for diameter wire (round shape), 0.9 mm for weft wire density, and 0.9 mm for diameter wire. The distance between each other is 8mm, the width is 63cm, the weaving form, the diameter wire and the weft wire are both in the form of cross winding, processed by the corresponding plastic mesh weaving machine, the plastic mesh is wound into a cylindrical mesh roll, and the mesh clip is inside the mesh clip (2b) Outer net folder (2c), the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com